I drew up a rough sketch and figured my angles first. I cut the slots into the tubing using our CNC plasma table and a piece of plate as a stop. Having a laser locator lets you really line up stuff like this.

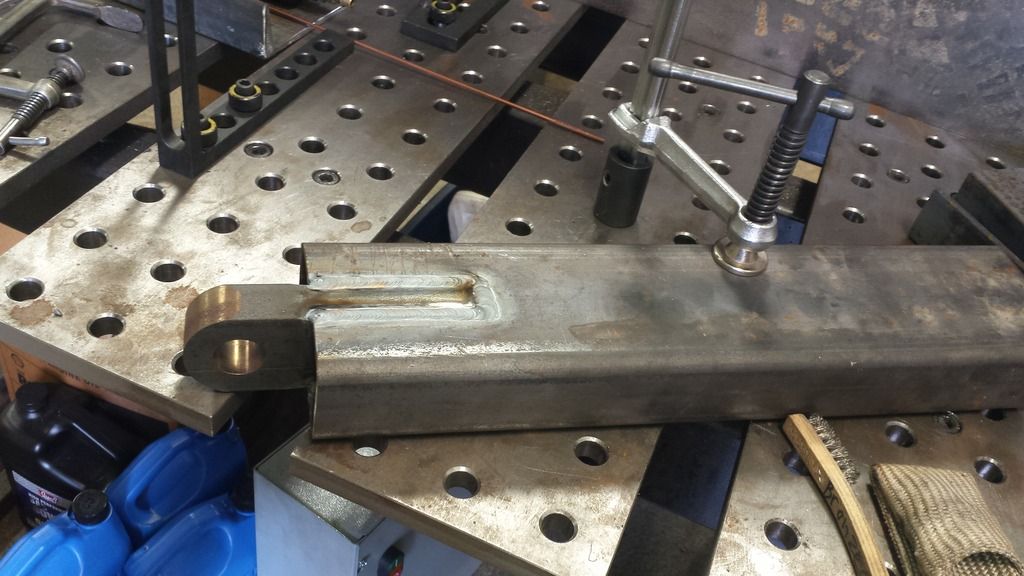

I already had some 1x2" bar with a hole and a radius on one end to act as a pivot for the top plates. Welded these up with my TIG machine.

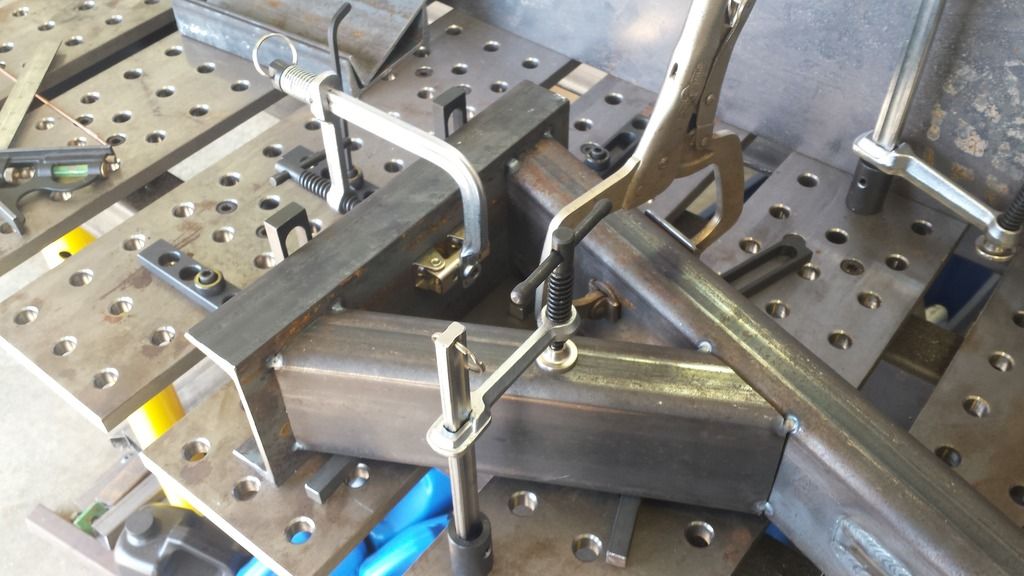

Next,I jigged the pieces up on my table and tacked them all together.

Speaking of the jig table, sometimes it just really handy for holding that piece in a good position to weld. It made getting into the tight angle a fairly easy.

I cut out these tabs from 1/2 plate and welded them to a piece of C channel to make the top pivot plates.

Closeup of the weld. I'd like to get a bit more consistent. I really don't get as much tig steel practice as I'd like.

We cut out some chain plates and bent up some handles for these.

Here they are in use. I had to order the chains I want to use with these. They will be welded to one side and attached with the chain plate to the other.