Well most if not all materials used where scraps or excess from other projects stocked in my garage. Using 2" GI pipes for the main body and some 1" GI pipes as well plus others. Decided to make this project to make cutting some logs for firewood easier. I have seen different variations on YouTube but decided instead of remaking or copying their designs, I'll make my own version and see how it will come out. Ok, plans were not set on paper, I just started the project with a clear mind of what I wanted to achieve, adding things here and there as it progresses.

Sorry for there were no pics taken during the initial stages but manage to take some during the middle and last stages up to the completion of the project.

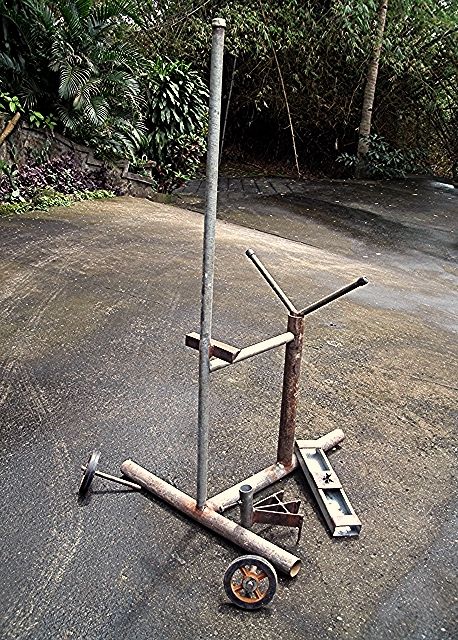

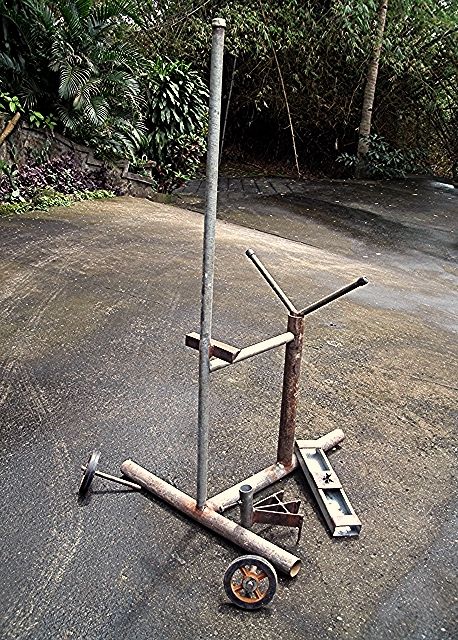

And this is somehow the cutting stand will come out with some of its accessories to be welded.

THE INITIAL ACCESSORIES TO BE USED:

The two 6" rubber wheels with its axles.

The movable clamping claws.