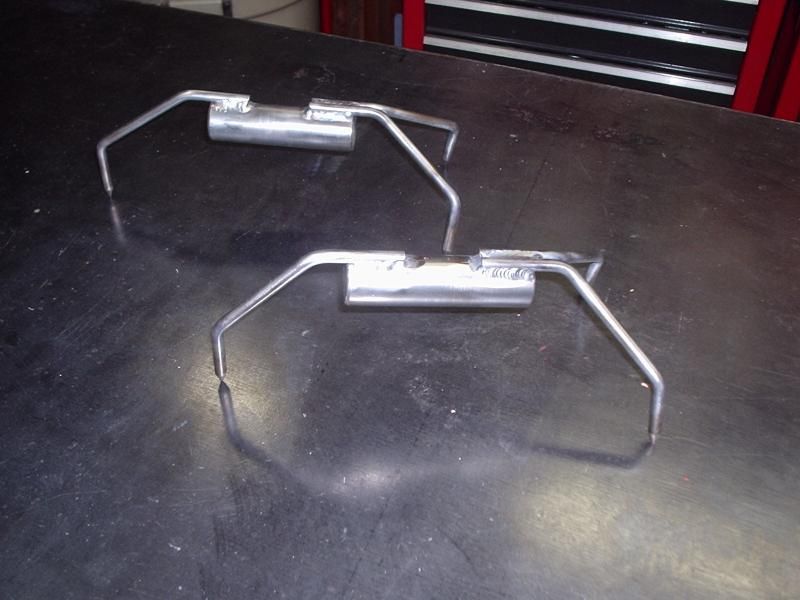

Each uses a 3" long piece of 1" diameter mild steel for the "weight", 1/4" mild steel rod for the two "legs", (each about 6" long), and a bent, sharpened 3/8" rod for the "neck" (I was thinking I'd want some extra weight up there, but in hindsight, 1/4" would have been easier to bend and probably would have been about as functional.

A tried a small variation on the design between the two. I ended up putting a little bend in the legs, to try and make an improvement in "table traction". (I will probably also end up sharpening the legs, for yet more traction.)

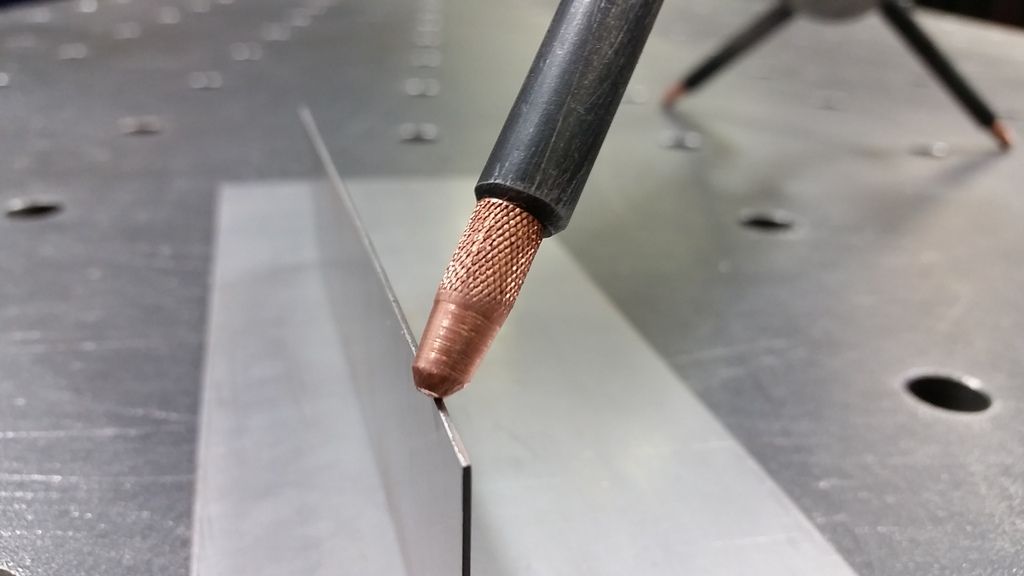

I used E70S6 filler for the first one with a small cup (looks like nothing special...) and for the second, tried some 309L stainless filler with a #8 gas lens cup and about 15 cfh. They were my first stainless TIG weld beads. The stainless filler made some real purdy looking weld beads, with neat color!

I am hopeful that these prove helpful in holding some small pieces in position for tack welding (especially aluminum pieces, because they are sometimes real hard to tack with one hand!) There is a forum post relating to these I made previously in this thread: http://forum.weldingtipsandtricks.com/v ... 1313#p1313