What welding projects are you working on? Are you proud of something you built?

How about posting some pics so other welders can get some ideas?

How about posting some pics so other welders can get some ideas?

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Ok I had to stop watching that after a minute or two. And that was pushing it for me. The noise of the CNC in the background was too much for my ears. And when he began discussing his plan to splice in a rudimentary DIY water cooler (which is the most diplomatic description I could conjure up) to the "110" of his 225X, I gave up the ghost. Definitely makes it into the Top-10 of the worst ideas I have heard this year. Sheesh!

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

Yeah, but don't say I didn't warn you, I tried to disclaim that pretty heavily.av8or1 wrote:Ok I had to stop watching that after a minute or two. And that was pushing it for me.

No argument from me. heheheav8or1 wrote:Definitely makes it into the Top-10 of the worst ideas I have heard this year. Sheesh!

Shows the inside of the box though, and that can be seen in the beginning.

v5cvbb (member here) did take some pics inside his Primeweld 225, but they were on his account to one of the photo sites, and I didn't want to post them. That dolt above shows the inside pretty well, though.

Collector of old Iron!

Alan

Alan

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

I dunno Alan, I couldn't have recommended that video to anyone, 'cept maybe as a submission for the Darwin awards, assuming those are still-a-thing.TraditionalToolworks wrote:Yeah, but don't say I didn't warn you, I tried to disclaim that pretty heavily.

Wasn't worth it, at least not for me it wasn't. I'll take the cover off of my own box prior to watching that...and I have no plans on removing my cover. So that should sum it up rather nicely.TraditionalToolworks wrote:Shows the inside of the box though, and that can be seen in the beginning.

Raining like it's never rained before in central TEXAS ... so no fab work to be had around my property for a few-to-several days. 'Gotta get a bigger shop!

Last edited by av8or1 on Wed Sep 09, 2020 6:02 pm, edited 1 time in total.

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I'm quite the opposite, I have to take everything apart, in fact Everlast (lugnuts specific) got mad at me for opening my green weenie and cleaning some of the spooged insulator plastic off the fan which it had wrapped around. v5cvbb's images were pretty good though, as I recall.av8or1 wrote:and I have no plans on removing my cover. So that should sum it up rather nicely.

I need to take everything apart, just my nature...

Collector of old Iron!

Alan

Alan

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Wha-? Do tell. Who was not happy with you and for what exactly? I ask because I was told that I needed to remove the cover from my 275p every so often and clean out the dust, etc. with compressed air or else my warranty was invalid. I remember thinking at the time that such notion was fairly ridiculous, but I have done it anyway. Every so often I remove the cover per what that fella told me and ever-so-gently apply compressed air to anything that looks dirty/dusty. Doing so taught me that a couple of those tiny sheet metal box screws are slightly longer than the others and thus must be used in certain places.TraditionalToolworks wrote:I'm quite the opposite, I have to take everything apart, in fact Everlast (lugnuts specific) got mad at me for opening my green weenie and cleaning some of the spooged insulator plastic off the fan which it had wrapped around.

I have a suggestion then if taking things apart is your thing: post your own video of the internals of your 225X box and include the link here! I'd have a look for certain.

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

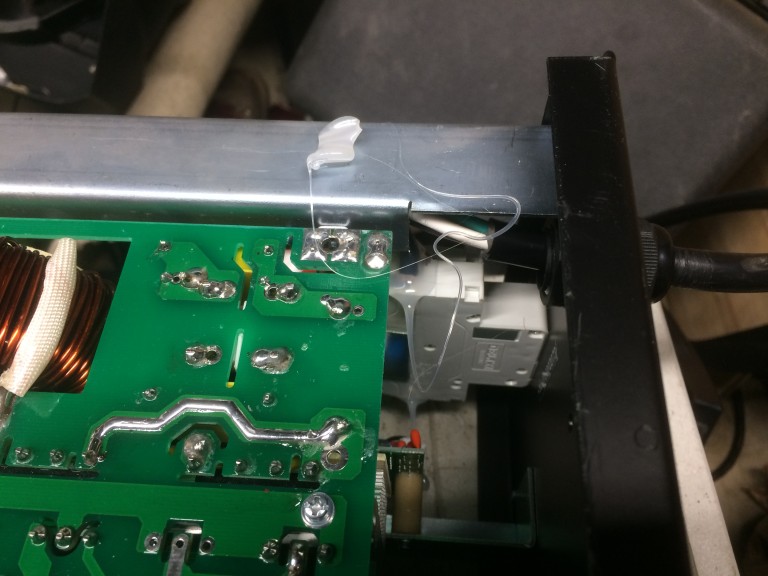

That part I was told also. I removed the cover to snap some pics inside, it didn't look too bad, but some of the insulator was spooged all over and it had dripped down on the fan.av8or1 wrote:Wha-? Do tell. Who was not happy with you and for what exactly? I ask because I was told that I needed to remove the cover from my 275p every so often and clean out the dust, etc. with compressed air or else my warranty was invalid.

When I first opened the box, this plastic booger fell out:

It was connected and wrapped around the fan, so I cleaned it off and removed it:

Mark told me I voided my warranty by doing so. I told him what he could lick and that if there was a problem with my welder in the warranty period I would hold them to fix it.

I also wanted to adjust my points for the HF start, but as it turned out the points in my machine are not the points that are pictured in the manual, mine has some cheaper points that need to have the metal bent to change the gap, but I was told not to touch anything or, again, I would void my warranty. He was primarily upset that I opened my machine and took pics to show the workmanship and/or quality that went into manufacturing it. He claimed how much better it was than Lincoln or other top names. That incident really soured me on Everlast. I dealt with Oleg direct myself, I drove up and did the transaction in person. Mark is a total lughead, lugnut is a misnomer. He's always saying bad stuff about the competition, he would be best to focus on Everlast and try to improve them.

I will if/when I do, but no reason to get p!$$y with me over some guy's video on YouTube. If you don't want to open your machine, no worries, I will open mine eventually, I would guess...just like I do most everything I own.av8or1 wrote:I have a suggestion then if taking things apart is your thing: post your own video of the internals of your 225X box and include the link here! I'd have a look for certain.

Collector of old Iron!

Alan

Alan

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I agree, you don't find that BS on Italian red, no argument. And Jeff doesn't tell you that you void your warranty for opening the box after he tells you to open it to blow it out or you void your warranty...Oscar wrote:That doesnt surprise me one bit. I'm tellin you all, go Italian red, but nnnoooooooo I dont wanna sell my kidney on the black market to switch to Italian red everyone saysyou only need one ! (Kidney)

But Primeweld doesn't tell you that either...

Collector of old Iron!

Alan

Alan

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Agreed. On both points. And he is the one who informed me of the periodic cleaning of the internals of the machine also.TraditionalToolworks wrote:Mark told me I voided my warranty by doing so. I told him what he could lick and that if there was a problem with my welder in the warranty period I would hold them to fix it.

[SNIP]

Mark is a total lughead, lugnut is a misnomer. He's always saying bad stuff about the competition, he would be best to focus on Everlast and try to improve them.

Wha-? Who is/was getting pissy? Certainly not me. That was actually a sincere suggestion. If you're into that sort of thing, you do it. I'd be interested to see the video of that. And that is intended on the up-n-up again, just as it was originally. But now to have a laugh with you ... don't you get pissy about perceiving that someone else is getting pissy.TraditionalToolworks wrote:I will if/when I do, but no reason to get p!$$y with me over some guy's video on YouTube. If you don't want to open your machine, no worries, I will open mine eventually, I would guess...just like I do most everything I own.

Too good.

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

My sentiment precisely Alan. Look Oscar, I was setting my sights on a red box. However I just couldn't justify the cost given the context of my usage. Period. If I was able to earn some type of side income from welding such that an investment in a red box would pay for itself, then I would definitely go in that direction. However that isn't the case and so I haven't. Nothing more than that. I would prefer the HTP 221, but as a family guy I can't do that.TraditionalToolworks wrote:I agree, you don't find that BS on Italian red, no argument. And Jeff doesn't tell you that you void your warranty for opening the box after he tells you to open it to blow it out or you void your warranty...Oscar wrote:That doesnt surprise me one bit. I'm tellin you all, go Italian red, but nnnoooooooo I dont wanna sell my kidney on the black market to switch to Italian red everyone saysyou only need one ! (Kidney)

But Primeweld doesn't tell you that either...

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I completely get it about being a family guy, wait until your little guy is in college, I just finished getting 2 kids through college and it ain't cheap these days. For me it's more about wanting to get my shop/home going, I'm looking for a 2nd lift so I can move machines and logs up to my property and have something to move them on the property end.av8or1 wrote:My sentiment precisely Alan. Look Oscar, I was setting my sights on a red box. However I just couldn't justify the cost given the context of my usage. Period. If I was able to earn some type of side income from welding such that an investment in a red box would pay for itself, then I would definitely go in that direction. However that isn't the case and so I haven't. Nothing more than that. I would prefer the HTP 221, but as a family guy I can't do that.

It's like all things in life, many people buy the best tools they can. I'm more convinced that Miller is the gold standard, but HTP is certainly not a bad sacrifice. I have to be a realist about the Primeweld, it's no Miller, HTP or Fronius. You can't expect too much for $800. It's quite a machine for $800 though, I will give it that.

Collector of old Iron!

Alan

Alan

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Congratulations regarding your achievement of getting your children through a higher level education. That is no small feat. We've started early with a generous initial installment into a 529 plan and still wonder if it will be enough...TraditionalToolworks wrote:I completely get it about being a family guy, wait until your little guy is in college, I just finished getting 2 kids through college and it ain't cheap these days. For me it's more about wanting to get my shop/home going, I'm looking for a 2nd lift so I can move machines and logs up to my property and have something to move them on the property end.

It's like all things in life, many people buy the best tools they can. I'm more convinced that Miller is the gold standard, but HTP is certainly not a bad sacrifice. I have to be a realist about the Primeweld, it's no Miller, HTP or Fronius. You can't expect too much for $800. It's quite a machine for $800 though, I will give it that.

Oh sure, I too don't view the 225X that I purchased to be anything other than it is. And it isn't a Miller or HTP or anything of the like. 'Never thought of it that way, never claimed it was. Rather, it is a good "beginner TIG welding box" as someone described it. However that's ok with me since I am in fact a beginning TIG welder and will likely never use it in any professional capacity. So for me it's not about buying the best tool I can, although that is a part of it, it is about buying the correct tool for my application context. And not breaking the family bank in the process.

It hasn't rained today thus far, so I might have an opportunity to do some fab stuff after work, depending on how wet the ground is. TBD. I'd like to finish off the plasma and move to building the TIG cart. Gotta think about that one a bit...haven't given it a single brain cycle just yet...

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I won't digress on this too much, and not sure where you're located, but this is a huge problem for parents, For UCs and State colleges in CA it's about $25k/semester (including housing), and in most cases the kids can't finish in 4 years to get their degree, so it's like $250k-$300k to get 1 child through college with a degree. Private school is more. My son went to UCLA, my daughter Cal Poly San Luis Obispo, both very respected schools. The UCs were intended to be affordable education in CA, but they are now considered to be the public ivys. Very hard to get in, many foreigners also. It's a problem, good luck to you.av8or1 wrote:Congratulations regarding your achievement of getting your children through a higher level education. That is no small feat. We've started early with a generous initial installment into a 529 plan and still wonder if it will be enough...

I was the one who described it that way, and I feel the same about myself. I'm not pro, but I do want to weld like one. I think it's a good machine for people like me, and better than many alternatives at much higher prices.av8or1 wrote:Oh sure, I too don't view the 225X that I purchased to be anything other than it is. And it isn't a Miller or HTP or anything of the like. 'Never thought of it that way, never claimed it was. Rather, it is a good "beginner TIG welding box" as someone described it.

I would say I'm similar but like good quality tools. Given my choice, I would select a Dynasty for TIG.av8or1 wrote:However that's ok with me since I am in fact a beginning TIG welder and will likely never use it in any professional capacity. So for me it's not about buying the best tool I can, although that is a part of it, it is about buying the correct tool for my application context. And not breaking the family bank in the process.

But the Primeweld fits my needs and more so fits the budget I currently wanted to spend. I have a massive project going on that is magnitudes more expensive, and coincidentally more dear to my heart.

Collector of old Iron!

Alan

Alan

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Thanks.

So I've been thinking about tungsten grinding. There are a number of ways to go about it obviously. Some of them become rather pricey, rather quickly. So I thought I'd ask what others do. Any feedback?

So I've been thinking about tungsten grinding. There are a number of ways to go about it obviously. Some of them become rather pricey, rather quickly. So I thought I'd ask what others do. Any feedback?

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I use a couple ways. I have an attachment for my Dremel that was about $40, it uses some small diamond wheels and has a collet. I only have a collet for 3/32", which is pretty much what I use mostly. I could make my own collets to fit in it on the lathe if I want, but I use 3/32" almost exclusively.

I also have a 6" diamond lapping disc, at least someone said it was a lapping disc here. There's a thread I posted somewhere in Product Reviews possibly. I bought 3 discs with different grits on ebay, 150, 400 and 1200. I have the 400 grit disc mounted on the side of one of my bench grinders and use the exposed area to sharpen. I chuck the electrode in my cordless drill. I use this primarily when the electrode gets horked and won't fit in the collet on the Dremel attachment, then after I get it down to size I use the Dremel attachment.

This is what they look like off the Dremel attachment.

I also have a 6" diamond lapping disc, at least someone said it was a lapping disc here. There's a thread I posted somewhere in Product Reviews possibly. I bought 3 discs with different grits on ebay, 150, 400 and 1200. I have the 400 grit disc mounted on the side of one of my bench grinders and use the exposed area to sharpen. I chuck the electrode in my cordless drill. I use this primarily when the electrode gets horked and won't fit in the collet on the Dremel attachment, then after I get it down to size I use the Dremel attachment.

This is what they look like off the Dremel attachment.

Collector of old Iron!

Alan

Alan

I chunk mine in a cordless drill and just sharpen on a grinding disc or flap disc depending on my expectations and how lazy I'm feeling in the moment. You should use a dedicated fresh disc for tungsten, but I don't usually bother. That said, tungsten is hard and if you use a worn out flap disc it's going to take a whole lot longer to sharpen a chewed up piece.

Sharpie tungsten grinder. Worth the money to get dead perfect, consistent results in a single step. Occasionally only will I follow up with a scotchbrite pads to remove any discoloration/oxidation (as Toolie's post shows).av8or1 wrote:Thanks.

So I've been thinking about tungsten grinding. There are a number of ways to go about it obviously. Some of them become rather pricey, rather quickly. So I thought I'd ask what others do. Any feedback?

If you want consistency and best results, proper tools.

av8or1

- av8or1

-

Ace

-

Posts:

-

Joined:Fri Aug 21, 2020 11:37 pm

-

Location:TEXAS

-

Contact:

Thank y'all for the replies. 'Preciate them.

I had been eyeing the HF bench top mini-grinder ever since I watched one of Kevin Caron's YouTube videos a while ago. He's since moved on to a larger variant. I researched that option too, but it became as expensive as a dedicated tungsten grinder once you factored in the cost of the diamond wheels. Since Oscar mentioned the cheap-o HF grinder in his reply, though he just uses the polishing half of it, I've decided to take a punt on this little critter. I found a 3" diamond wheel on Amazon with the 1/2" bore that the mini-me has. Mixed reviews on whether or not it will fit. 'Spose I'll find out soon enough.

You're only about $60 all-in with this option, so it seemed attempt worthy. I'll report back in a few days once I have the two in-hand and have tried them.

Thanks again!

I had been eyeing the HF bench top mini-grinder ever since I watched one of Kevin Caron's YouTube videos a while ago. He's since moved on to a larger variant. I researched that option too, but it became as expensive as a dedicated tungsten grinder once you factored in the cost of the diamond wheels. Since Oscar mentioned the cheap-o HF grinder in his reply, though he just uses the polishing half of it, I've decided to take a punt on this little critter. I found a 3" diamond wheel on Amazon with the 1/2" bore that the mini-me has. Mixed reviews on whether or not it will fit. 'Spose I'll find out soon enough.

You're only about $60 all-in with this option, so it seemed attempt worthy. I'll report back in a few days once I have the two in-hand and have tried them.

Thanks again!

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I completely agree, one day I will probably have one. For the time being my Dremel attachment is working out ok it uses similar discs, but the one problem is it doesn't have a cutoff and when a glob gets on the end of the tungsten and it won't fit in, I need to take it to the grinder. I can kind of cut the tungsten on the edge of the lapping disc, but it's not ideal. One thing is for certain, tungsten is tough $#!T...cj737 wrote:Sharpie tungsten grinder. Worth the money to get dead perfect, consistent results in a single step.

I'll have to try the scotchbrite pad to clean the oxidation, I'm usually more worried about the globs when I really stick the tungsten or jam the filler hard. $#!T happens...

Collector of old Iron!

Alan

Alan

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

I've seen you post this pic before, but I have to ask you, often in other pics you show a much more blunt tip to people and show a very small stickout on your tungsten, most often recommending they use that style.Oscar wrote:Hand sharpening on an alum oxide and silicon carbide wheel on a regular bench grinder. Follow up with a polishing wheel on a harbor freight 3" mini grinder.

That is completely different than these long shallow tungsten you show all shinny and polished here.

Which style do you use when you tig? And why the discrepancy in the tungstens?

Those do look beautiful, but I don't think I have time to polish mine like that, I just do them in batches before I sit down to tig, if I see the slightest change in the tip I drop it out and put a new one in. I most often go through 3-4 during a session, some I probably don't need to swap out but I do as I will notice a change in the end of the point, sometimes if I notice color difference which probably makes no difference.

I have never sharpened any of mine so shallow of an angle like that, and that entirely walks in the face of how you show others to tig weld, so you have me confused. My Dremel sharpener doesn't have adjustable angle, and that's how mine come off the wheel when I sharpen and use them. Takes me about 2-3 minutes to freshen up the few used ones to have a batch like I have in my hand above.

Collector of old Iron!

Alan

Alan

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

Quite honestly I'd like to see more of his applications/projects.Poland308 wrote:I’m guessing like most of us Oscar varies his grind angle to the given application.

I suspect he pulls out those polished tungstens when it seems appropriate to show off some shiny metal. But I'm not faulting him for that, just that I don't see those tungstens being too useful with how shallow the angle is, call me a skeptic.

My wife says I'm too honest with people at times...Ya think?

Collector of old Iron!

Alan

Alan

Return to “Welding Projects - Welding project Ideas - Welding project plans”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities