Page 1 of 1

First Beads

Posted: Mon May 25, 2015 1:01 am

by yamahablue

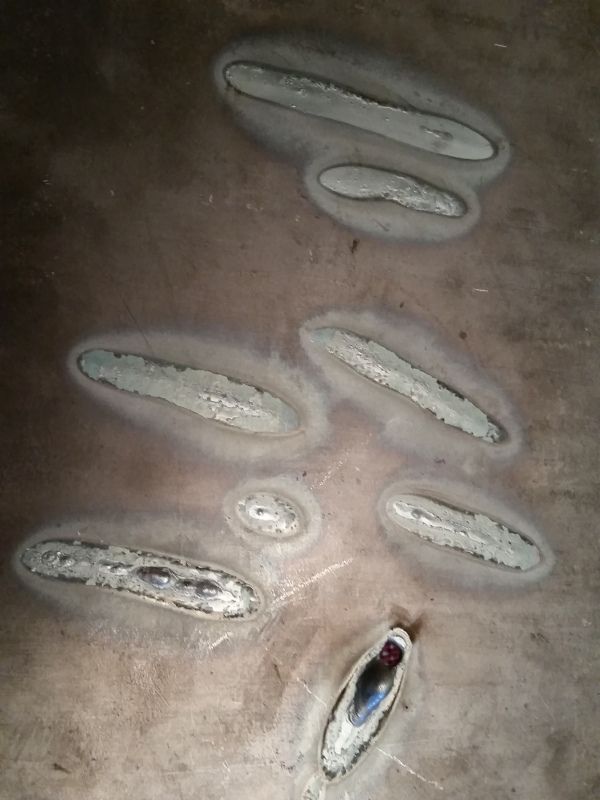

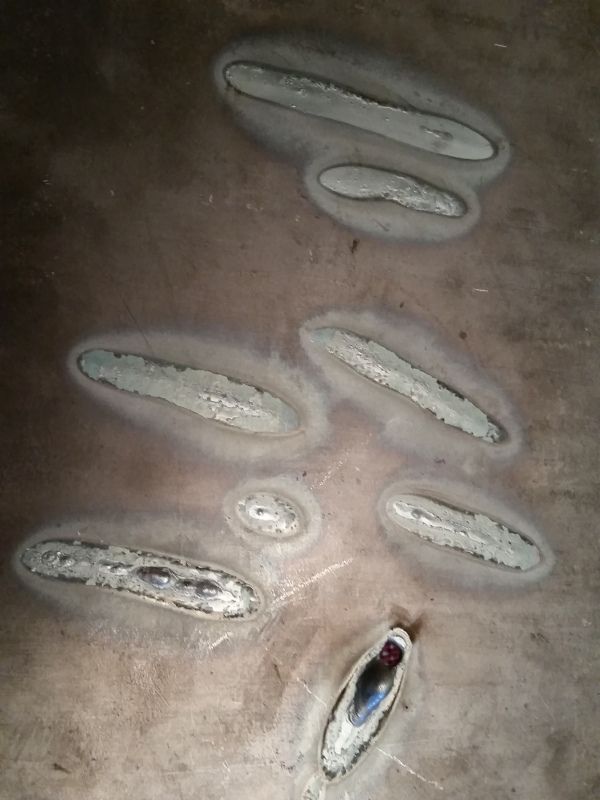

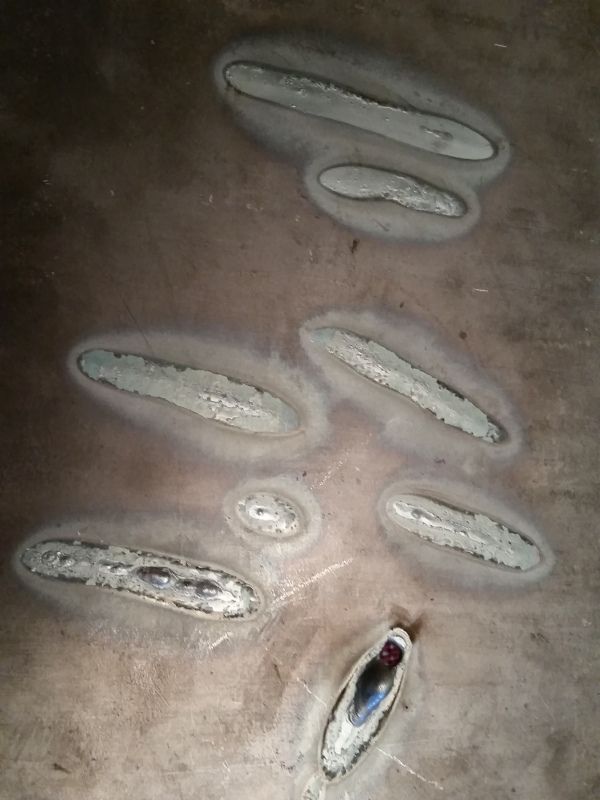

I've said this in my other threads but I'm brand new to welding, this is my first try at mig. I bought a millermatic 211 maybe a month ago and finally got a tank and gas for it a couple days ago. I still need a cart, gloves and some other misc items but I couldn't wait. I hooked up the gas grabbed a piece of 1/8" and ran a few beads. I didn't clean it, could that be why it has that burnt color around the welds? Also seemed to have more spatter than I expected, could that also be from not prepping it right, or not enough gas flow?

I was plugged into 230 with it on autoset at the low range of 1/8", the burn through was my first pass, I tried a couple setting it manually using the door chart and then went back to the auto set. All expect 1 were done pulling, pushing I couldn't see what I was doing, nozzle was in the way. Anyway I don't know if anything can even be seen from the pictures but here they are, also you can see it warped the crap out of the metal.

Before cleaning

Bottom

Warpage

Re: First Beads

Posted: Mon May 25, 2015 1:08 am

by yamahablue

Re: First Beads

Posted: Mon May 25, 2015 1:59 am

by weldin mike 27

All of that is completely normal. Especially for a first timer. The spatter is because the settings are not quite right. But tuning the machine will come with practice.

Re: First Beads

Posted: Mon May 25, 2015 7:28 pm

by yamahablue

I was surprised that it burned through, that flux core didn't and I went slower and ran longer beads. Overall this seemed hot or that I needed to move faster than expected. Is it normal for a good portion of the weld to stay glowing red after stopping?

When making changes to minimize spatter where would I start? One setting at a time or both?

Re: First Beads

Posted: Mon May 25, 2015 10:17 pm

by weldin mike 27

Again normal, burn thru is avoided by practice regarding travel speed. The glowing red is normal. It takes a fair deal of heat to melt metal. With the spatter, it can be caused by a number of things. One being excessive wire speed. Leave the volts set where they are, and gradually lower the w/s unroll you get a nice crackle. Don't go too far or you will get a hissing popping noise.

Re: First Beads

Posted: Mon May 25, 2015 11:51 pm

by yamahablue

Thank you.

Re: First Beads

Posted: Tue May 26, 2015 1:36 am

by weldin mike 27

No problem mate

Re: First Beads

Posted: Wed May 27, 2015 8:44 am

by TRACKRANGER

Mike's exactly right about the sound. It should sound like bacon sizzling in a pan. Short and sharp. I think Jody mentioned words like that in one of his videos. I remember thinking 'what an appropriate description!'

Re: First Beads

Posted: Wed May 27, 2015 12:37 pm

by yamahablue

I was watching some of his mig welding videos the other night, good stuff. I don't know why it is but it looks like his travel speed is slower than I feel is possible in my case.

Re: First Beads

Posted: Wed May 27, 2015 6:51 pm

by Otto Nobedder

yamahablue wrote:I was surprised that it burned through, that flux core didn't and I went slower and ran longer beads. Overall this seemed hot or that I needed to move faster than expected. Is it normal for a good portion of the weld to stay glowing red after stopping?

When making changes to minimize spatter where would I start? One setting at a time or both?

"Generally";

Too much spatter means too much wire speed for the voltage. Conversely, it can mean too little voltage for the wire speed.

Given the picture, my choice would be to increase voltage first, but I doubt you can do that much with a 90A machine.

Back the wire down until the spatter is under control.

My best suggestion based on what I see and the information you've given.

Steve S

Re: First Beads

Posted: Wed May 27, 2015 9:05 pm

by yamahablue

Otto Nobedder wrote:yamahablue wrote:I was surprised that it burned through, that flux core didn't and I went slower and ran longer beads. Overall this seemed hot or that I needed to move faster than expected. Is it normal for a good portion of the weld to stay glowing red after stopping?

When making changes to minimize spatter where would I start? One setting at a time or both?

"Generally";

Too much spatter means too much wire speed for the voltage. Conversely, it can mean too little voltage for the wire speed.

Given the picture, my choice would be to increase voltage first, but I doubt you can do that much with a 90A machine.

Back the wire down until the spatter is under control.

My best suggestion based on what I see and the information you've given.

.

Steve S

I'll give that a try. Yeah that 90a machine only has a min and max setting and wire speed. I probably won't ever use that machine again it's my 211 that I would like to get dialed in with solid wire.

Re: First Beads

Posted: Wed Apr 27, 2016 10:57 pm

by yamahablue

I haven't been practicing like I should or would like to but I had a couple drops sitting in the garage and decided to run a couple beads. Hopefully the pictures show enough to get some advice from you guys.

I didn't clean the scale off of any of it and set the machine by the chart for 3/16. Doing the 3/16 to the 10g (bottom) I dropped the wire speed a little. Most of it I tried a whip I think it's called, pushing out and then back. The bottom bead, 2/3 of it on the right was just a straight push.

I would like to know if there's a way to avoid cutting into the top piece so much, maybe nozzle position?

Re: First Beads

Posted: Thu Apr 28, 2016 8:46 pm

by yamahablue

I guess I should add that this is done with the 211, 230v, .030 and 75/25 gas. The material thickness is the same that I'll be working with on my project, 3/16 flat onto 10g or so.

Hoping to get some advice so that the actual project turns out better than this.

Re: First Beads

Posted: Thu Apr 28, 2016 9:50 pm

by Poland308

Try focusing less on the movement pattern but more on steady even travel. This will help you get a feel for the puddle and let you watch for keeping the wire shooting at the leading edge. It will leave you with a smoother looking bead but give you some confidence.

Re: First Beads

Posted: Fri Apr 29, 2016 4:09 am

by Backsheddave

Some good advice above. Have you downloaded the Miller welding App. I've found this useful for getting welder settings close so you can fine tune from there. You say you don't have a welding cart yet. Once you get a handle on running some decent beeds, why not make your own. I did this while learning to tig aluminium, and found it an excellent learning curve. Welding out of position etc. That's my 5 cents worth.......... Enjoy!

Re: First Beads

Posted: Fri Apr 29, 2016 10:31 am

by yamahablue

Thanks, I'll look into the miller welding app. Since originally starting this thread I have purchased a cart.

One of the beads pictured, at least most of it, was done without any type of motion. I'm wondering why the welds cut into the top of the thicker material so much but dont look to be tied in well on the bottom. Maybe cause the mil scale?

Re: First Beads

Posted: Fri Apr 29, 2016 7:19 pm

by Otto Nobedder

yamahablue wrote:Thanks, I'll look into the miller welding app. Since originally starting this thread I have purchased a cart.

One of the beads pictured, at least most of it, was done without any type of motion. I'm wondering why the welds cut into the top of the thicker material so much but dont look to be tied in well on the bottom. Maybe cause the mil scale?

The mill scale will affect tie-in on the bottom, but in a lap joint it's very hard not to cut in to the top edge, especially when it's sharp. A point is where heat will concentrate most, having nowhere to go, and it will melt quickly and unpredictably. Try chamfering over the corner on the top piece, to make a slightly rounded edge, and this problem will be reduced. Only hood time will eliminate it.

Steve S

Re: First Beads

Posted: Fri Apr 29, 2016 9:13 pm

by yamahablue

Thank you, that's good to know. I'll give that a try.

Re: First Beads

Posted: Sat Apr 30, 2016 4:01 am

by Backsheddave

Could also be something as simple as gun angle. Maybe a slight eeeeeeee pattern may help, really it's about having a bit if a play with the advice given and what works for you.

Re: First Beads

Posted: Wed May 04, 2016 11:00 pm

by yamahablue

I tried prying up on the top piece to see what would happen. I knew the tie in looked questionable on the 10g but I didn't expect that the weld would lift completely off. It wasn't very easy to pry it up but definitely didn't penetrate. The little glob that stuck might have been a tack weld, not sure why it seperated from the weld. This was the section I tried just a straight stringer bead.

The end circled in red I used some forward and back movement, it seemed to be holding on better.

I'm a little surprised considering the machine was set closer to the thicker metal setting. Is this the result of welding over mil scale? Also, is it difficult to get fusion welding onto a tack weld?