Page 1 of 1

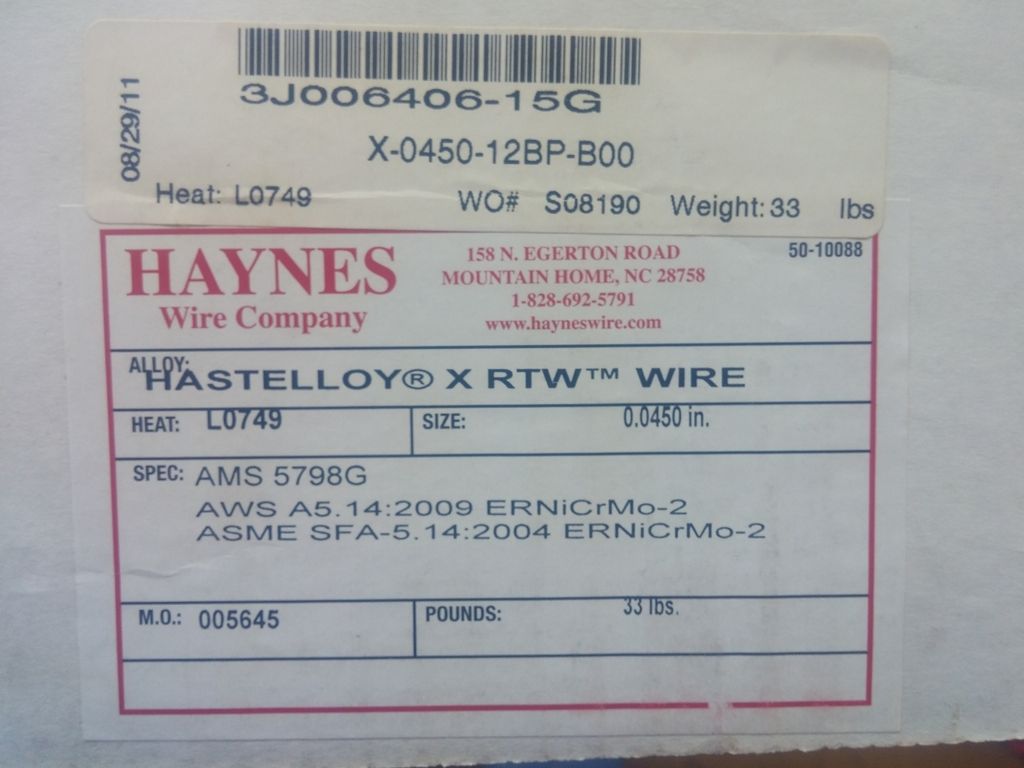

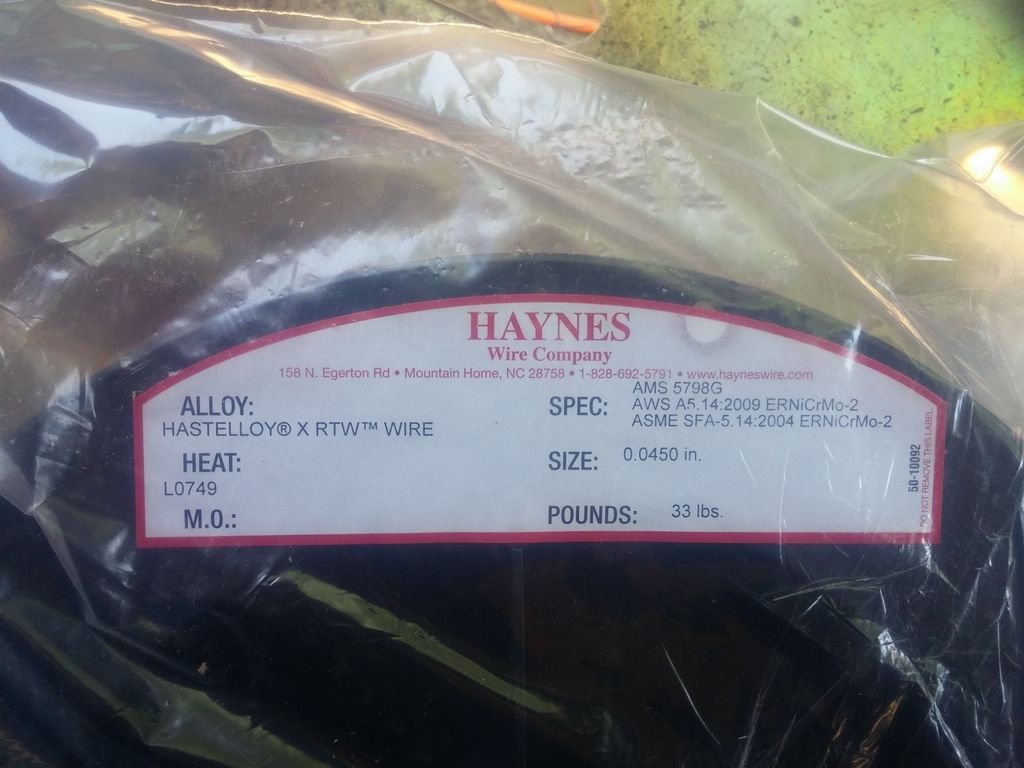

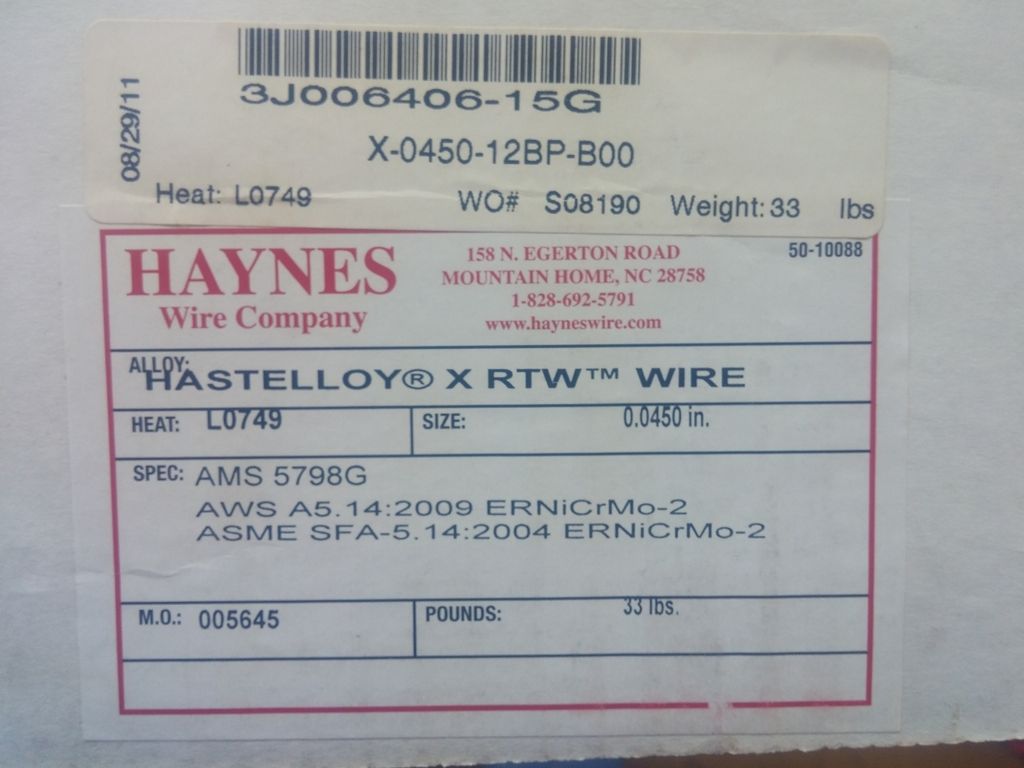

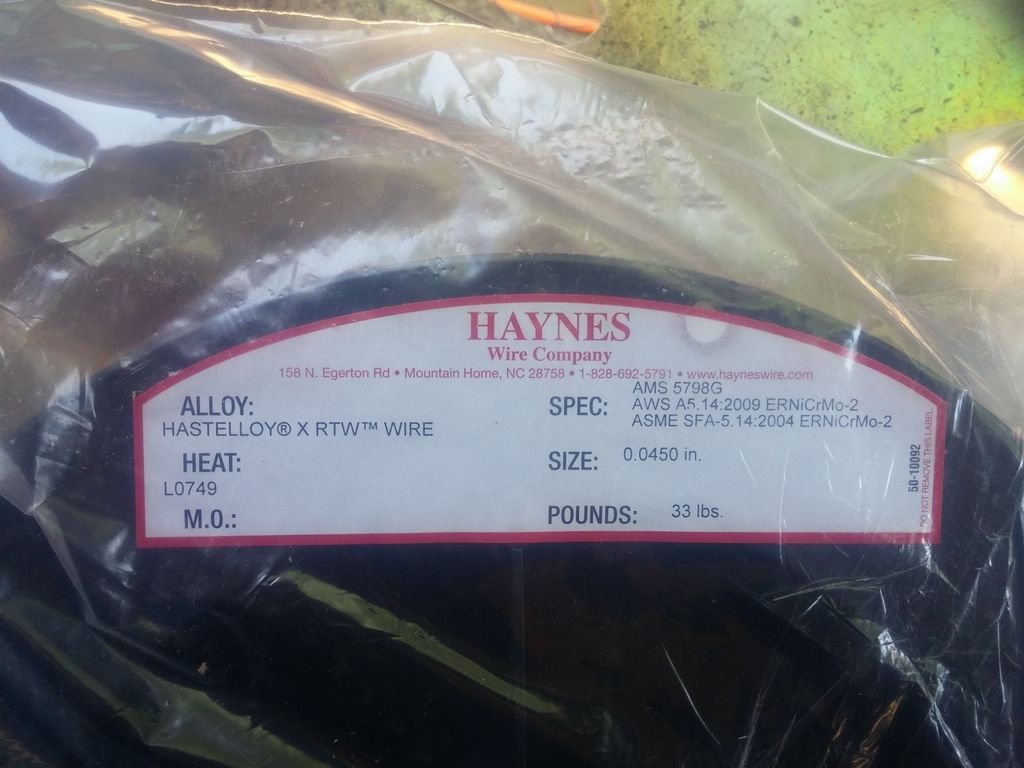

Anyone use Hastelloy X?

Posted: Mon Jun 13, 2016 2:52 pm

by Oscar

Re: Anyone use Hastelloy X?

Posted: Mon Jun 13, 2016 3:50 pm

by DLewis0289

Hastelloy=$$$$$$$$$$$$$

Just out of curiosity how did you get a hold of a roll of Hastelloy-C? Usually only used in chem plants with corrosive processes stainless steel won't handle.

Just noticed it is X not C, has hi temp properties as well as superior corrosion resistance.

Re: Anyone use Hastelloy X?

Posted: Mon Jun 13, 2016 4:00 pm

by Oscar

DLewis0289 wrote:Hastelloy=$$$$$$$$$$$$$

Just out of curiosity how did you get a hold of a roll of Hastelloy-C? Usually only used in chem plants with corrosive processes stainless steel won't handle.

Just noticed it is X not C, has hi temp properties as well as superior corrosion resistance.

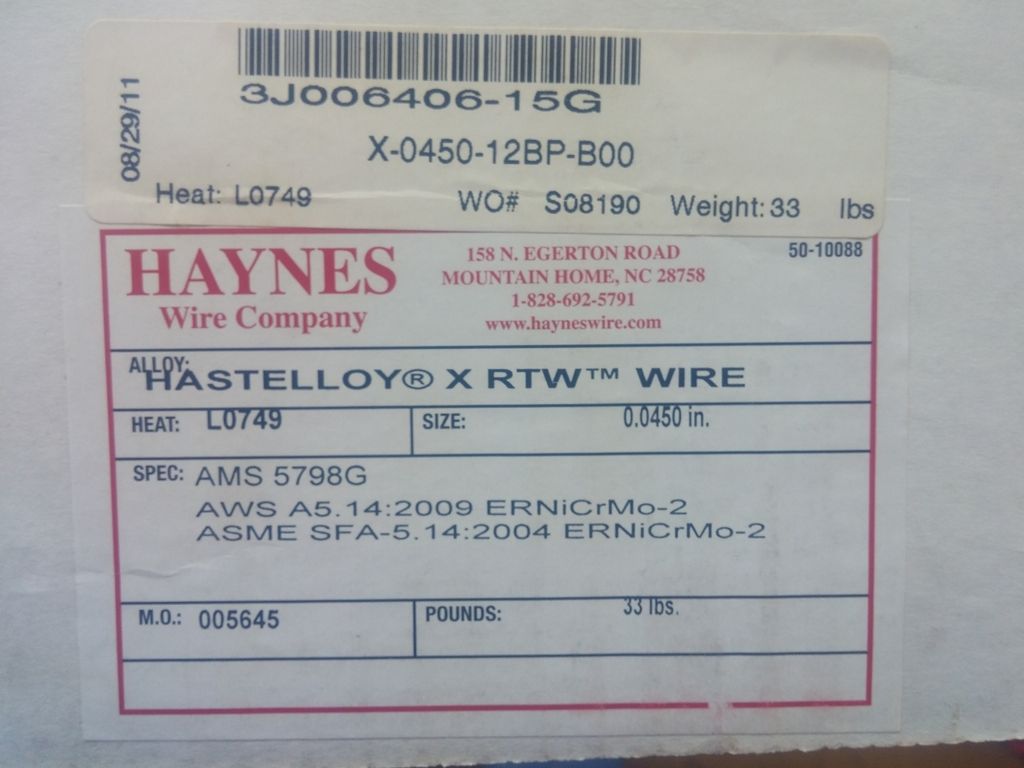

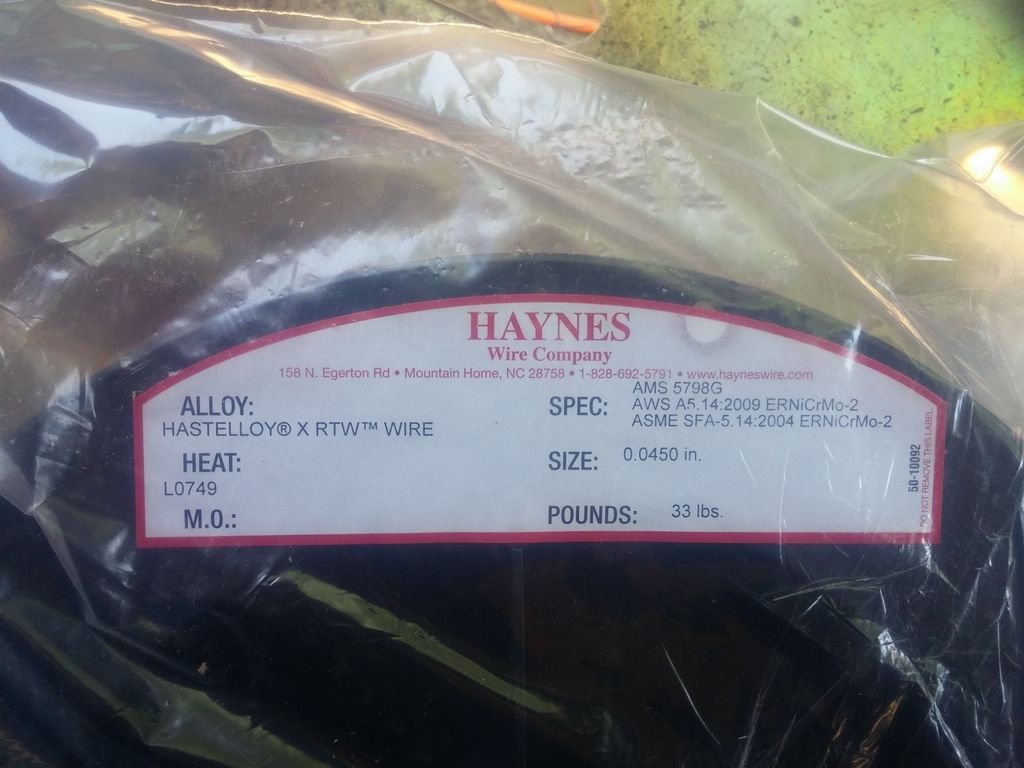

Easy: Ebay

Re: Anyone use Hastelloy X?

Posted: Sat Jul 16, 2016 7:22 pm

by Oscar

So, for filler wire of this caliber, naturally I had to wait until a very sensitive weld procedure called for it. Something with insanely strict and specific procedures to properly utilize it's extreme corrosion and heat resistance.

Turns out I hated having to reach for a socket when I want to switch polarities from MIG w/ 70S-6 to Flux-core on my Millermatic 211. It has two small flanged nuts that are recessed into small plastic "pockets", so you have to reach for a socket.

So I TIG'd some wingnuts onto the back of the stock nuts. With Hastelloy-X.

Incredibly precise jigs/fixturing to hold tight tolerances.

Puddle flows nice and smooth, reminds me of 304L. Now I can switch polarities quicker. I don't have a rotary positioner to chuck these up in, so bear with me.

Here they are installed and tightened.

The End.

Re: Anyone use Hastelloy X?

Posted: Sat Jul 16, 2016 8:28 pm

by Rick_H

Well..wheres the WPS

Sweet find, that's an expensive roll of wire

Re: Anyone use Hastelloy X?

Posted: Sat Jul 16, 2016 8:43 pm

by Oscar

Rick_H wrote:Well..wheres the WPS

You're lookin' at it, in the pictures. LOL.