Page 1 of 3

Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 3:40 pm

by DSM8

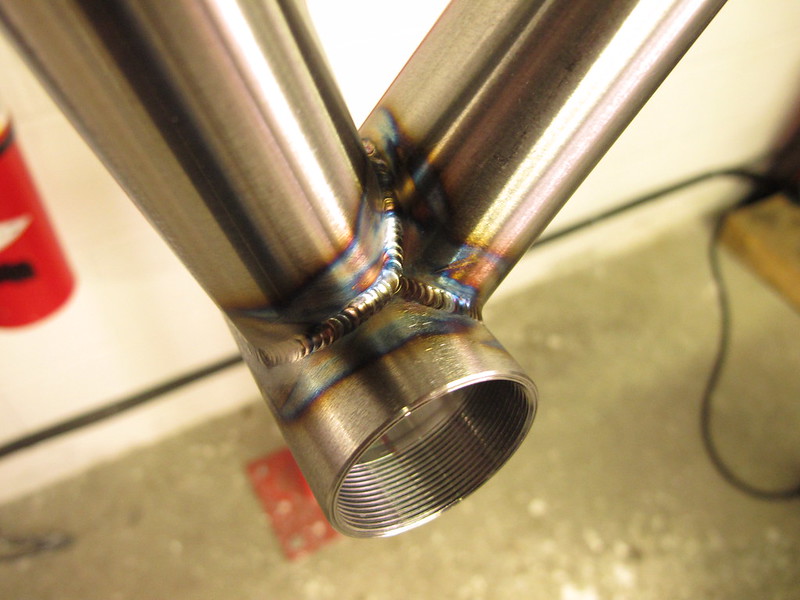

So I tried this for the first time ever.

Machine is a Miller Diararc 300HF (1984 Vintage)

2% Cerriated electode

15cfm of gas

Mid point of amperage setting on the machine

It looks like the heat effected zone is good and the penetration seemed decent based on the inside of the tube it was welded too. A little ugly of a weld though.

Anything that stands out as an issue in what the Guru's can see from the rather poor picture.

Video with more detail:

http://dsm8.smugmug.com/Other/Welding/4 ... B&lb=1&s=A

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 5:41 pm

by Oscar

It doesn't look bad at all, but I can't help but notice one thing that happened in reverse: why did you wire brush the weld joint AFTER the fact? If you're going to go through the trouble of wire brushing/wheeling, you're better off doing it prior to welding it to get it as clean as possible. Chromoly doesn't develop heavy millscale like plain carbon steel, but like I said, if you're gonna do it, might as well do it before hand.

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 5:51 pm

by DSM8

Actually it was wire brushed before and after just to remove some of the carbon buildup hiding the detail of the weld.

I did not get it down to shinny metal though of the tub I welded it too, was just being lazy so I believe there was some contamination of the weld due to that.

If you watch the video you can actually get a shot of the inside of the tube to see the heat ring/penetration.

Like I said first time ever doing this material, damn hard going around those little things...

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 7:08 pm

by Oscar

Yea small diameter round tubing is always tricky. I need to practice on some right now in fact

Try getting it shiny bright down to bare metal and use longer pieces on the transverse piece, and you will likely get better welds (less grayish oxidation). What size cup are you using? I'd use no smaller than #8 since there is no place for argon to get trapped like when doing corner/fillet joints.

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 7:22 pm

by DSM8

Oscar wrote:Yea small diameter round tubing is always tricky. I need to practice on some right now in fact

Try getting it shiny bright down to bare metal and use longer pieces on the transverse piece, and you will likely get better welds (less grayish oxidation). What size cup are you using? I'd use no smaller than #8 since there is no place for argon to get trapped like when doing corner/fillet joints.

I think it was a #8 with a gas lens. Also in an area with no drafts for the very reason you mentioned.

So then what DOES a good weld on this material look like?

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 7:26 pm

by Superiorwelding

DSM8 wrote:Oscar wrote:Yea small diameter round tubing is always tricky. I need to practice on some right now in fact

Try getting it shiny bright down to bare metal and use longer pieces on the transverse piece, and you will likely get better welds (less grayish oxidation). What size cup are you using? I'd use no smaller than #8 since there is no place for argon to get trapped like when doing corner/fillet joints.

I think it was a #8 with a gas lens. Also in an area with no drafts for the very reason you mentioned.

So then what DOES a good weld on this material look like?

Good.

-Jonathan

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 8:41 pm

by Otto Nobedder

DSM8, just roll with it...

That's one very good first/early go.

Like painting a car, the prep affects the results as much as the application. Don't neglect the cleaning. Hell, don't neglect anything you can control, so your handiwork is the biggest variable.

Steve S

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 10:20 pm

by Oscar

DSM8 wrote:Oscar wrote:Yea small diameter round tubing is always tricky. I need to practice on some right now in fact

Try getting it shiny bright down to bare metal and use longer pieces on the transverse piece, and you will likely get better welds (less grayish oxidation). What size cup are you using? I'd use no smaller than #8 since there is no place for argon to get trapped like when doing corner/fillet joints.

I think it was a #8 with a gas lens. Also in an area with no drafts for the very reason you mentioned.

So then what DOES a good weld on this material look like?

even with video, it's hard to capture detail, so I'm not meaning to say it looks bad. Thing is, once you brush it, you remove all visible traces of oxidation. Not that it's a bad thing, not like it's stainless steel or anything.

Basically it should look like a nice clean carbon steel weld, somewhat shiny if there is enough gas coverage and post-flow.

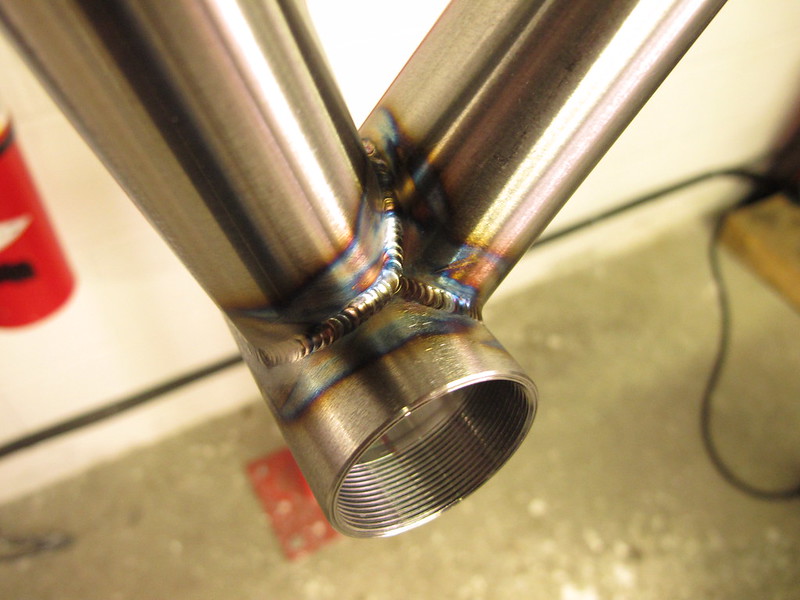

Edit: just whipped this up, from some pieces laying around....1-1/8" OD, 16ga wall

Clean and shiny witha roloc flapper

Holding them in a tube-holding jig-thingee I made for exhaust stuff

Small tacks around

Doing about 1/2" around the tube before I had to re-position it, back-stepping. 60A on the welder, using foot-pedal, but no pulsing of any kind.

I used some ER70-S6 I had laying around just scotch-brite'd it and wiped it with acetone.

Yup, it's always a challenge, that's for sure!

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 10:33 pm

by Superiorwelding

Who cares about your weld Oscar, lets see that jig a little better.

-Jonathan

P.S. weld looks ok too.

Re: Tig Welding Cromolly Tubing

Posted: Mon Dec 29, 2014 10:44 pm

by Oscar

Superiorwelding wrote:Who cares about your weld Oscar, lets see that jig a little better.

-Jonathan

P.S. weld looks ok too.

Thanks, I think! lol

You're actually seeing the jig in it's entirety in that second pic. The three wing-nuts loosen to adjust the V-opening and the tubing positioning, and the nuts just above the secondary wing-nuts loosen to rotate the mini C-clamp deals I made about a different plane. So in total there are 5-degrees of freedom (adjustment points), so it can hold two tubes/pipes in darn near any orientation, including ones that are already curved butted up, or even coped-up at weird angles.

Some more for your viewing enjoyment

Re: Tig Welding Cromolly Tubing

Posted: Tue Dec 30, 2014 12:16 pm

by DSM8

Ill take one where do I mail the check to ?

but seriously...I want one. That is a fantastic bit of creative dickery there.

Oscar wrote:Superiorwelding wrote:Who cares about your weld Oscar, lets see that jig a little better.

-Jonathan

P.S. weld looks ok too.

Thanks, I think! lol

You're actually seeing the jig in it's entirety in that second pic. The three wing-nuts loosen to adjust the V-opening and the tubing positioning, and the nuts just above the secondary wing-nuts loosen to rotate the mini C-clamp deals I made about a different plane. So in total there are 5-degrees of freedom (adjustment points), so it can hold two tubes/pipes in darn near any orientation, including ones that are already curved butted up, or even coped-up at weird angles.

Some more for your viewing enjoyment

Re: Tig Welding Cromolly Tubing

Posted: Tue Dec 30, 2014 2:22 pm

by Oscar

I'll make you one for $20

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 11:18 am

by kiwi2wheels

@ Oscar

Great idea ! Thanks for posting.

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 1:09 pm

by motox

oscar

i love it when someone whips up what is necessary to get it

done..

simple genus

craig

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 1:12 pm

by motox

hope you don't have it patented

i hate stealing patented ideas lol

craig

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 4:26 pm

by Oscar

motox wrote:hope you don't have it patented

i hate stealing patented ideas lol

craig

No patent, but feel free to send me TIG welding supplies to show your appreciation, perhaps a single tungsten.

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 4:28 pm

by DSM8

Oscar wrote:motox wrote:hope you don't have it patented

i hate stealing patented ideas lol

craig

No patent, but feel free to send me TIG welding supplies to show your appreciation, perhaps a single tungsten.

One balled up, discolored and contaminated tungsten on it's way.

Where do you want it mailed?

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 5:41 pm

by Oscar

DSM8 wrote:Oscar wrote:motox wrote:hope you don't have it patented

i hate stealing patented ideas lol

craig

No patent, but feel free to send me TIG welding supplies to show your appreciation, perhaps a single tungsten.

One balled up, discolored and contaminated tungsten on it's way.

Where do you want it mailed?

thanks for the offer, lol. I have more tungtens than I'll ever need, and still ordering more from HTP just in case China decides to triple the cost of tungsten/rare earth metals. Must stay a step ahead of inflation/greed.

I will take some Grade-5 6AL-4V titanium tig rod if ya got it though!!

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 7:16 pm

by motox

how about a six pack of Belgian Ale!

Re: Tig Welding Cromolly Tubing

Posted: Wed Dec 31, 2014 11:00 pm

by Otto Nobedder

motox wrote:how about a six pack of Belgian Ale!

I'll trade a good weld for a six-pack of real Belgian Ale!

Steve S

Re: Tig Welding Cromolly Tubing

Posted: Thu Jan 01, 2015 12:00 am

by MinnesotaDave

Otto Nobedder wrote:motox wrote:how about a six pack of Belgian Ale!

I'll trade a good weld for a six-pack of real Belgian Ale!

Steve S

Hell Steve, I've been known to trade a good weld for Bud Light and cheap whiskey

Re: Tig Welding Cromolly Tubing

Posted: Thu Jan 01, 2015 6:06 pm

by zank

DSM8 wrote:

I think it was a #8 with a gas lens. Also in an area with no drafts for the very reason you mentioned.

So then what DOES a good weld on this material look like?

With ER70s-2 wire and a #7 cup, I shoot for something like this.

Re: Tig Welding Cromolly Tubing

Posted: Thu Jan 01, 2015 6:15 pm

by zank

I think your first attempt looks great. As you practice more, you'll anticipate spots that are trickier for you. But the video looks great from where I'm sitting.

Re: Tig Welding Cromolly Tubing

Posted: Mon Jan 05, 2015 8:51 pm

by DSM8

Thanks for all the tips so basically from what I am coming to understand when welding Chromolly.

A proper weld will still be shinny after the pass from the torch has cooled.

That assumption is from the picture of the bike frame above.

Is this correct, and if so does that mean my heat imput is too much, gas flow too little for amps or just moving too fast?

Pipe I did was 120 wall. Used ER70S2 whatever filler rod. gas flow at 15 on the flow meter.

Re: Tig Welding Cromolly Tubing

Posted: Tue Jan 06, 2015 12:54 am

by Oscar

Improper torch angle and excessive stick out also contribut significantly to weld head appearance.