Page 1 of 1

Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 3:00 am

by brad72

Hi All. This is my first post here so hi to you all and thanks for any advice you can give me.

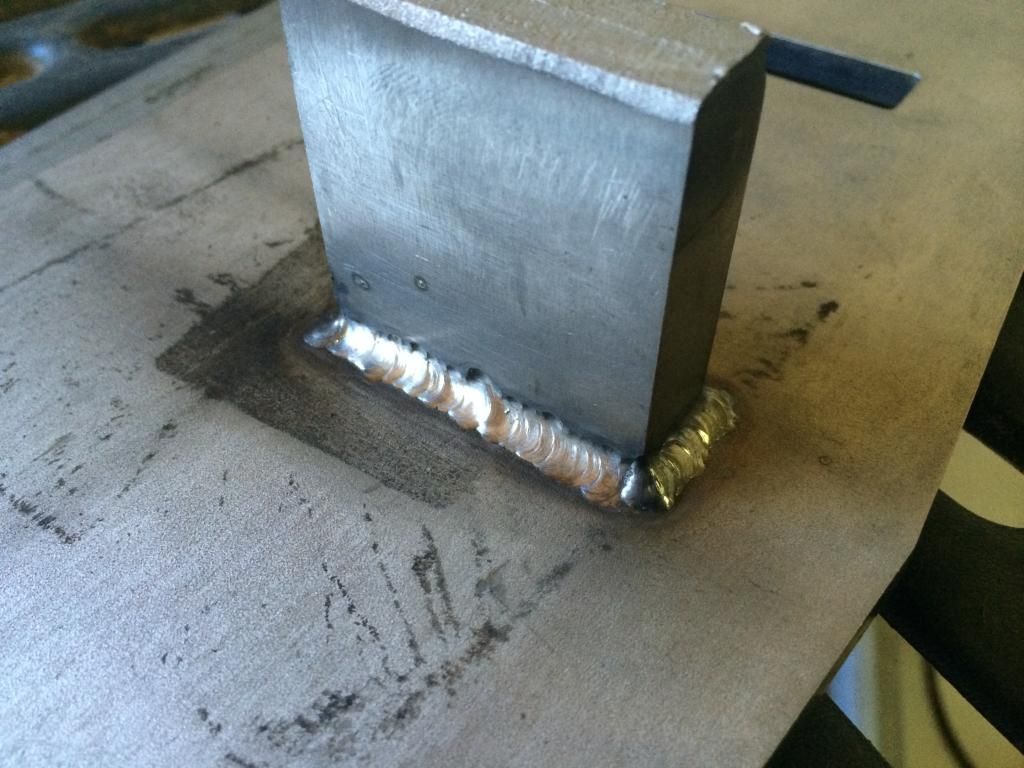

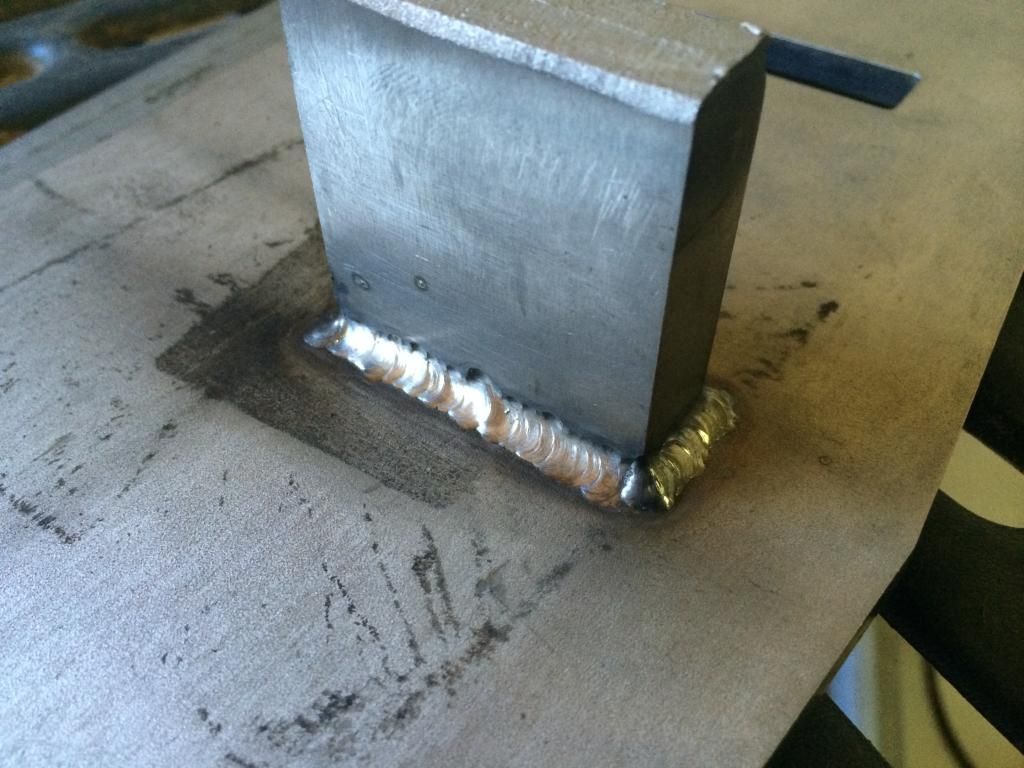

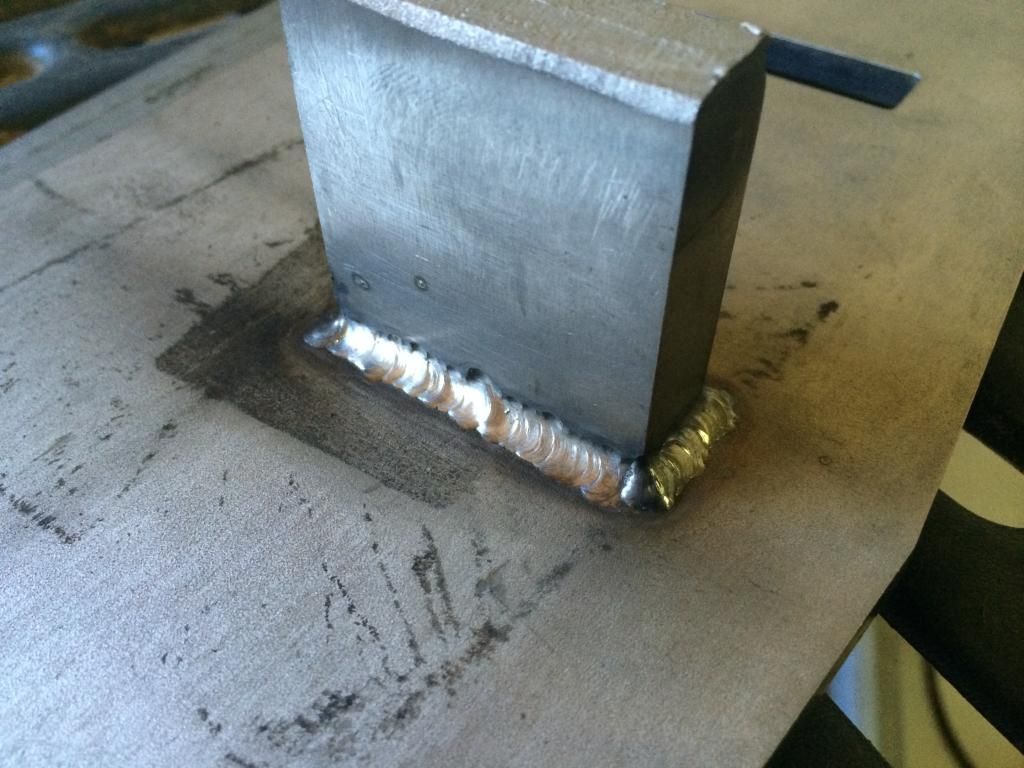

I am welding some 5/8" x 1.5" flat bar at right angles to a plate of 8" wide 5/16" thick stainless as per the pictures below (please ignore the undercut in the test piece). I have done a few test welds with different amps and weld paths but even with clamping a 1" thick alloy backing plate and letting the job air cool I am still getting distortion in the 5/16" plate. I realize that the position of the weld on the plate is always going to be problematic but because the underside will be mirror polished any distortion stands out terribly. The actual bar I will be welding will be wing shaped rather than rectangular but I cannot see that making too much difference to the distortion

I have thought of welding in smaller runs, letting it cool then do the next weld rather than get in , get out technique I am currently using.

If any of you could you offer me some suggestions in reducing the distortion that would be great.

Thanks

Brad

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 8:14 am

by weldin mike 27

Hey,

First off, stainless always pulls like a mother, always. Its because of the low thermal conductivity. A good way of fighting distortion, is to "pre-set' the part that is distorting. This means finding out how much the part moves and pre bending it the opposite way before hand, so when it bends from heat, it ends up closer to where you want it. Also, if you have more than 1 to build, tack them together back to back, so that they pull against each other, maybe with a bit of tig wire in between to add some preset. PS with the ss, youll need decent tacks or it will just break.

Mick

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 5:27 pm

by brad72

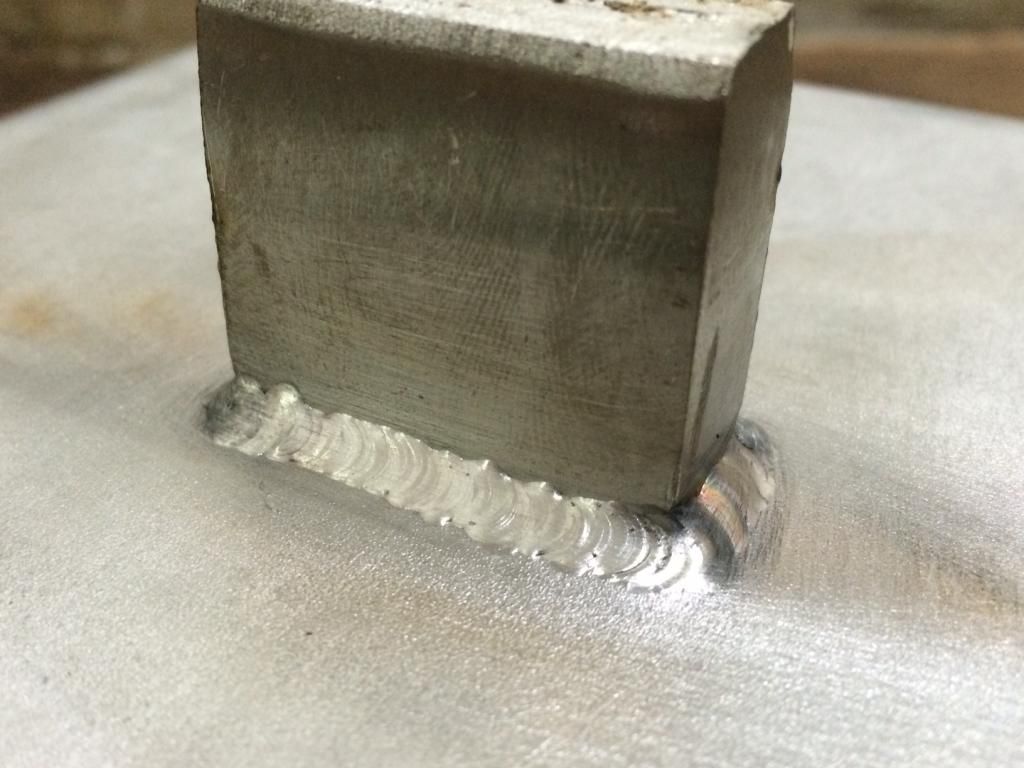

Thanks Mick. I pre-stressed the job using some 1.6mm wire underneath the weld zone and clamping either side. Hit it with 170 amps, let it air cool and it came out pretty much dead flat in all directions.

thanks again.

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 7:27 pm

by weldin mike 27

Awesome, I'm glad it worked.

Mick

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 9:17 pm

by jcw

Very cool solution. I have to remember that one!

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 9:38 pm

by brad72

Re: Distortion in 5/16" stainless plate

Posted: Tue Sep 16, 2014 10:11 pm

by weldin mike 27

B-E-A-utiful.

Mick

Re: Distortion in 5/16" stainless plate

Posted: Wed Sep 17, 2014 4:19 am

by Tater

Nice- that's the old time method called "breaking the back," still used in our machine shop.

Re: Distortion in 5/16" stainless plate

Posted: Wed Sep 17, 2014 10:32 am

by Rick_H

I use the same method all the time....amazing what just a little back bend will do.

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 4:23 am

by Legion

At what stage do you take out the wire? I guess seeing as you have to unclamp only when it's all room temperature again?

I mildly warped some 10mm mild steel plate doing something similar on the weekend even though I was careful, slow, stepping around and clamped it hard to some straight heavy square tube. I was thinking about the wire trick beforehand but didn't use it but still after cooling I got enough warping to annoy me.

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 5:32 am

by weldin mike 27

Hey mate. Yep wait till room temp, or possible a little hotter but not too much. The way distortion works is that it expands as it is hot, the as it cools and then goes past where it started, hence the warp.

Mick

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 6:51 am

by MinnesotaDave

Best intro video into warping, in my opinion, is "Mr. Shrink"

http://youtu.be/2vuGlcbDwKY

http://youtu.be/2vuGlcbDwKY

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 7:00 am

by brad72

Legion wrote:At what stage do you take out the wire? I guess seeing as you have to unclamp only when it's all room temperature again?

I mildly warped some 10mm mild steel plate doing something similar on the weekend even though I was careful, slow, stepping around and clamped it hard to some straight heavy square tube. I was thinking about the wire trick beforehand but didn't use it but still after cooling I got enough warping to annoy me.

Yep, leave the wire in until it has cooled. I was shocked at how much warping I got clamping to 1" thick alloy plate as a heat sink. Stainless doese love to pull

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 7:12 pm

by brad72

Enjoyed the video. Agree with you, probably the best description of shrinkage I have ever seen. Always nice to see the theory behind the practice.

Re: Distortion in 5/16" stainless plate

Posted: Thu Sep 18, 2014 9:50 pm

by forrestderp

That was an awesome video! I love how the progression of technologies have changed so vastly that stick welding is pretty much done in field environments and occasionally on high strength parts.

I worked in a shop building food grade augers and it was amazing how twisted they would get and with dial indicators and using our friend shrink you could easily bring them back to true.