Page 1 of 3

Helmet and welding advise

Posted: Sun Aug 24, 2014 5:11 pm

by TwentyFourSeven

I am very new to welding. Two weeks ago I never welded anything in my life. I own a pool fence company, I was useing a welder to make my gates but paying out the butt for it and he became un reliable so I just bought a Lincoln tig 225 (very nice machine) The aluminum tube for the gates is only 1/16" thick. I have the Lincoln auto dark helmet. The problem I am having is the amps are turned down to 60 to weld the thin aluminum. Even then most of the time the foot peddle is only half way down. This obviously makes the arc not very bright and the lowest the helmet will go is 9. I can not see very well on the lowest setting. I have a manual helmet with a #7 lens in it and its pretty bright and allows me to see perfect but does not have the luxury that comes with the auto dark helmet. I have a couple of questions.

First question, how do I know if 7 is not dark enough and damaging my eyes while tig welding at 60 amps? I am not getting any red dots left in my eyes and I have instant vision when I stop welding. I might try an 8 lens but the 9 is definatly too dark with the low amps.

Second question, does anyone make a helmet that auto darks any lower than a 9? What is everyone else doing who is tig welding with low amps?

I am cutting the 1/16" aluminum tubing at 45* angles and just butting them tight together. I am then welding all the way around the seam. I blew a few holes in it at first but after a few hours I finally got it. The outside corners get grinded down smooth but the weld stays on the inside corner. Is this the best way to be doing this? Should I be beveling the edge of the tubing with a grinder to leave room for filler rod? Should I just be leaving a gap for filler? I think I will be switching electrode to 2% Lanthanated after seeing the youtube comparison test. Thanks in advance for any tips. Oh yeah, I just bought 2 tig fingers.

Re: Helmet advise

Posted: Mon Aug 25, 2014 3:43 pm

by Adam's Got Skills

Personally i don't use a lens any lower than #8. As far as ur hood i know alot of the more inexpensive auto darkening hoods have a lower amp limit say the cheap one is 40 amps the expensive is 5 or less. Ur probably under the lower limit. An as far as ur fence goes i don't thing ur doing anything wrong. as a general rule OSHA says a handrail fall protection only needs to be tested to 200lbs of force back an fourth. If it does that it'll keep someone out of the pool. I think ur on the right track tho polish the outside leave the weld inside

Re: Helmet advise

Posted: Mon Aug 25, 2014 4:19 pm

by Braehill

24/7,

I'm not being critical of you for doing what you're doing in any way and we can answer most questions about the welding and probably the helmet, but I think the weld procedure should be brought to an engineer. We even have some of those who contribute here, but you're talking about someone's safety depending on your gates to hold up and that means your welds. I would think that this comes with a certain amount of liability on your part that now can't be passed onto anyone else.

It would also be better if you showed a picture of the weld joint in question and then you should receive more input as to the best way to weld it. again, we can help you learn to weld and you'll have to decide if you're good enough to weld the gates and put your companies name on them.

Len

Re: Helmet advise

Posted: Mon Aug 25, 2014 9:41 pm

by TwentyFourSeven

I have actually gotten very good at the gates over the last few days. I have gone through 2 bottle of argon. I can take some pictures of the jigs, welds and cuts I have been doing. I am doing it the same way the welder with 30yrs experience was doing it. There are also other model gates from China and other companies in the USA that do it the same way. I have purposely been bending and breaking the pipe to see how my welds have been holding up. The pipe always eventually gave and snapped, the welds have been holding strong. I have also been cutting the corners of with a chop saw to inspect the welds and they are melted and fused together pretty good. It has been a bitch to learn on such a thin aluminum pipe but I finally got it (After countless hours watching youtube videos and reading all of the tips n tricks here). Its very sensitive to the amps and my foot is up and down on the peddle a lot. I do believe I am going to switch to an auto dark helmet that goes down to an 8, the 9 is just a hair to dark when I have my foot half way down on the peddle. Thanks again for the help.

Re: Helmet advise

Posted: Mon Aug 25, 2014 10:42 pm

by Superiorwelding

24/7,

I don't know where to start on the welding questions. I have to be honest, if you are building fences that keep children from drowning and you might be questioning your welds, maybe you should rethink this. Being honest again, two weeks welding and building fences like that, that worries me a little. I am not saying you can't weld or shouldn't just have to be honest. Of course the other way to look at it is if you only have two weeks in and have the skill to weld 1/16" alum that's pretty good.

For a helmet, I use the Jackaon Truesight. The weld mode goes down to 9 and the torch mode is 5-8. This gives you a full range. Not a cheap helmet but it is good.

-Jonathan

Re: Helmet advise

Posted: Tue Aug 26, 2014 12:55 am

by 79jasper

I've seen some that go lower, gonna get one eventually. Just look some up online, they'll say the range.

I've been told by multiple instructors, that as long as there's a lense of some sort, you won't get UV damage to your eyes. You can have too bright of light come through and mess with you, but not supposed to be permanent. Don't know if it's true or not.

I started out with mine set to the minimum (9), now I run dark as I can still see.

Sent from my SM-G900R4 using Tapatalk

Re: Helmet advise

Posted: Tue Aug 26, 2014 6:40 am

by noddybrian

Most auto dark helmets commonly around at the moment seem to provide shades 9 thru 13 for welding & 5 thru 8 for plasma in two separate ranges - but I'm sure a place I worked kept fixed shade 7 or 8 for low amps - it's worth trying a dual range even if only a cheapy to decide if it helps you - if after a days welding you have sore eyes then go up a shade - many charts list amps around 50 / 60 & lower suiting shade 7 - I realize this has been discussed before - but it's worth mentioning contributing factors on seeing the weld include insufficient or shadowy ambient light - the arc alone is not enough for Tig - make sure the area is well lit in such a way as to eliminate shadows around the weld joint - make sure your eyesight is 100% - maybe go to a quality optician & have them checked / or glasses checked - as Tig produces no appreciable fumes learn to weld with your head closer than you maybe used to when doing arc or mig - use a cup size suitable to the joint configuration & consider a gas lens to allow more " stick out " hence allowing better view & more light from the arc / weld pool - on thicker material I would suggest prepping the outside corner of the joint to allow for less build up though this may not be practical on your material thickness - it's not something I weld - hopefully if you post some pictures one of the aluminum gurus such as TamJeff or the bicycle dude will chime in as are kings of this material especially in tube joints - as to previously mentioned liability I imagine your product is way better made than a mass produced thing from a foreign country - but you should make sure you have relevant insurance to cover yourself & they may insist you take a test for this material & process - hopefully not insisting on a WPS as well - alternatively if you send an example to a recognized testing facility they should be able to provide a fail / yield strength in the products normally used position - from this figure in the safety factor & then you can include a sticker stating the products maximum design criteria - so if the gate which is meant to protect say 5year old & under children from drowning is broken by one of these Mc children that weigh 150lbs aged 8 then your still in the clear as clearly it's not the intended usage of the gate - think of it like crash barrier on a road - our original type here was only designed to contain within that lane a vehicle of 1.5ton striking it at not more than 50 MPH at an angle of not greater than 15 degrees - so obviously it will not keep a semi from crossing into oncoming traffic - you cannot blame the barrier's makers - it's just outside the design remit.

found this snippet on shades - hope it helps

http://ppeforum.blogspot.co.uk/2010/08/ ... enses.html

Re: Helmet advise

Posted: Tue Aug 26, 2014 7:49 am

by TwentyFourSeven

Thanks for all the advise and concerns. Trust me I am not just going to throw this in to production without having everything 100% tried and looked at by some one. The fact that it's all ready being done with the same materials and working is a big help alone. I am using the recommended amps and electrode (60) 1/16" I might bump the amps up a bit because on the inside corner it takes forever for the metal to start to melt, I am wasting gas waiting. The outside corner is a diffrent story, that instantly melts and if I'm not carefull it quickly blows a hole in it. The inside is the easy part to weld, the outside corner is the bitch. The frame is laying flat on a table so when I start on the inside corner it's like tigging up hill, then flat across the top as I tig towards my self, then the outside corner is down hill with no steady way to rest my hands.

Re: Helmet advise

Posted: Tue Aug 26, 2014 12:07 pm

by AFSATCOM

My question would be how is the lighting situation where you're working. If you have too much light coming in from the back of the hood it can make it difficult to see what's goin on. I will occasionally use a shop light too light up the joint better as well. Sometimes it's a night and day difference. I've worked at 5 amps with the #9 and could see very clearly. But everyone's a bit different.

Re: Helmet advise

Posted: Tue Aug 26, 2014 10:13 pm

by TwentyFourSeven

Good advise and yes I have noticed the shop is a bit dark especially when I pull the garage door down half way to shade my self from the sun. I am adding a second 8' strip light above. I got some pictures today so I will try get them on here as soon as I have a minute. Today I got 10 frames welded, the last one of the day took me 30 minutes to do. I am getting faster, the material is very sensitive to too much heat. I have to press the foot peddle down and up continuously.

Re: Helmet advise

Posted: Wed Aug 27, 2014 12:23 am

by 'Stang

I would personally recommend you try the Esab A/D hood. I bought one when one of my my buddies at my LWS recomended it. The Esab hood dials down for tig. Mine goes from 6 to 13. The clarity is amazing! The colors stay true. When you light up on aluminum, the aluminum stays silver. You can actually see the blue spark come off the tungsten. ArcOne also make a great hood that will dial down for low amp tig. I have the Vision Extreme. Great viewing area. I can run lower amps and still see where I am going. It all depends on what your budget allows. Good luck. Just get the best you can afford. And collect as many as you can afford! Lol.

http://forum.weldingtipsandtricks.com/p ... f=5&t=5862#

Re: Helmet advise

Posted: Wed Aug 27, 2014 7:16 am

by TwentyFourSeven

Thank you, sounds like what im looking for . I will check that out.

Re: Helmet advise

Posted: Wed Aug 27, 2014 8:28 am

by kiwi2wheels

Hello 'Stang,

Is this the model you have ;

http://www.spawelding.co.uk/online-stor ... elmet.html

Do you have the same clarity on DC, i.e., no red flare around the arc ? Thank you.

Re: Helmet advise

Posted: Wed Aug 27, 2014 9:35 pm

by TwentyFourSeven

Re: Helmet advise

Posted: Wed Aug 27, 2014 9:45 pm

by Braehill

24/7,

If you're as new to welding as your OP suggests, then you're doing way better than I expected. Your welds look fine and seat time should only make them better. Keep after it.

Len

Re: Helmet advise

Posted: Wed Aug 27, 2014 10:38 pm

by 79jasper

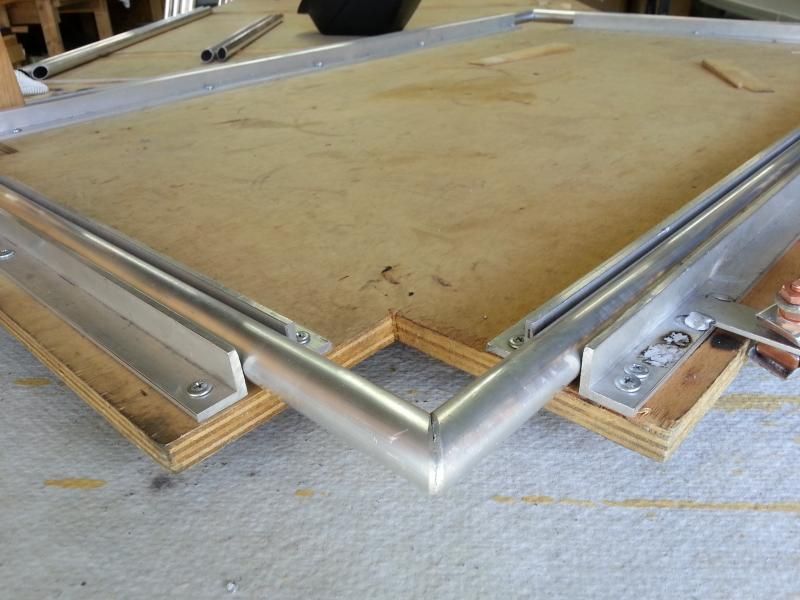

Nice little jig.

I would add connecting ground straps between them. Maybe overkill, but never hurts.

Sent from my SM-G900R4 using Tapatalk

Re: Helmet advise

Posted: Wed Aug 27, 2014 10:40 pm

by TwentyFourSeven

Thank you. The reason might be because I actually enjoy it very much. I can sit and weld all day long and the time fly's by. This thin stuff is extremely sensitive, burnt a few hole at first because I thought I could find a spot on the foot peddle and keep it there but the heat builds to much because it's so thin and all the sudden it just separates.

Jasper that's not a bad idea and thanks for the compliment, might help with some of the little black groves I'm getting in the side of the pipes from the ground arcs. Any way to avoid those little black arc spots other than directly clamping the ground to the pipe?

Re: Helmet advise

Posted: Wed Aug 27, 2014 10:44 pm

by Braehill

24/7,

Take about a foot or so of 1/0 welding cable and strip it bare, then coil this around your pipe and hook your ground to the two ends. Works great. Learned that trick from the Jedi (Jody).

Len

Re: Helmet advise

Posted: Thu Aug 28, 2014 12:01 am

by TwentyFourSeven

Good idea.

Re: Helmet advise

Posted: Thu Aug 28, 2014 10:19 am

by rick9345

'Stang wrote:I would personally recommend you try the Esab A/D hood. I bought one when one of my my buddies at my LWS recomended it. The Esab hood dials down for tig. Mine goes from 6 to 13. The clarity is amazing! The colors stay true. When you light up on aluminum, the aluminum stays silver. You can actually see the blue spark come off the tungsten. ArcOne also make a great hood that will dial down for low amp tig. I have the Vision Extreme. Great viewing area. I can run lower amps and still see where I am going. It all depends on what your budget allows. Good luck. Just get the best you can afford. And collect as many as you can afford! Lol.

http://forum.weldingtipsandtricks.com/p ... f=5&t=5862#

Got one about 1 1/2 yrs ago.Bit the bullet paid the price,couldn't have worked out better. At

low amps a little bit more tungsten stick out so

Lens sensor can see arc helps the auto dark. Sometimes a towel over my head to prevent back lighting inside helmet helps or turn off shop lights and just a light on work

Re: Helmet advise

Posted: Sat Aug 30, 2014 10:49 pm

by 'Stang

Hey Kiwi! Sorry for the late reply. Been working long hours this week. That is the model I have. I can't give you and answer about the clarity on DC. I haven't tried it yet. I have a project going in the shop with some 16 gauge carbon tube tomorrow. I'll try it and let you know. I usually use my Miller or ArcOne on carbon. But I'll give the Easb a try tomorrow.

Re: Helmet advise

Posted: Sun Aug 31, 2014 2:20 am

by jims-wings

Hi I am a new member, I have been welding for 45 years stick and mig but want to get into tig.

I will be buying a 6-13 shade helmet as sometimes i have a problem with seeing when useing the mig. my current auto goes down to 9, I also had a problem with bifocal glasses not being able to see at the required angle so I went to the optician and got a pair with lenses that give me perfect focus at around 14" (35cm) just a bit of a nusance when you stop welding and the workshop is a bit of a blur.

Re: Helmet advise

Posted: Sun Aug 31, 2014 8:04 am

by TwentyFourSeven

I also started practicing welding the gate trusses that go on either side of the gates. The aluminum is 1/8" I have about 6 hrs of practice. Here's my welds so far this is the best I can do. Anyone see anything that needs to be improved?

Re: Helmet advise

Posted: Sun Aug 31, 2014 3:05 pm

by kiwi2wheels

'Stang wrote:

Hey Kiwi! Sorry for the late reply. Been working long hours this week. That is the model I have. I can't give you and answer about the clarity on DC. I haven't tried it yet. I have a project going in the shop with some 16 gauge carbon tube tomorrow. I'll try it and let you know. I usually use my Miller or ArcOne on carbon. But I'll give the Easb a try tomorrow.

No worries 'Stang, many thanks for your reply. Funny, I just got myself some glasses with the same focal range as

jims-wings , am looking forward to being able to see what I'm doing sometime soon !

Re: Helmet advise

Posted: Sun Aug 31, 2014 6:09 pm

by Oscar

My Optrel e680 autodarkens down to a 5 and all the way up to 13. Love that helmet. worth every penny