Page 1 of 1

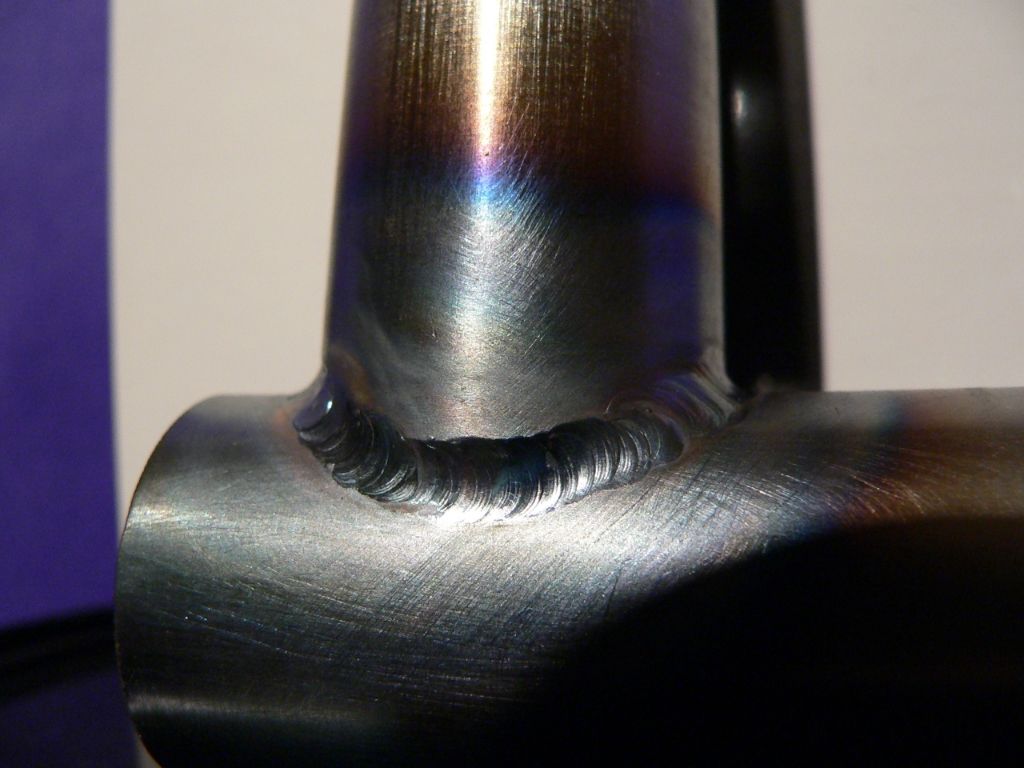

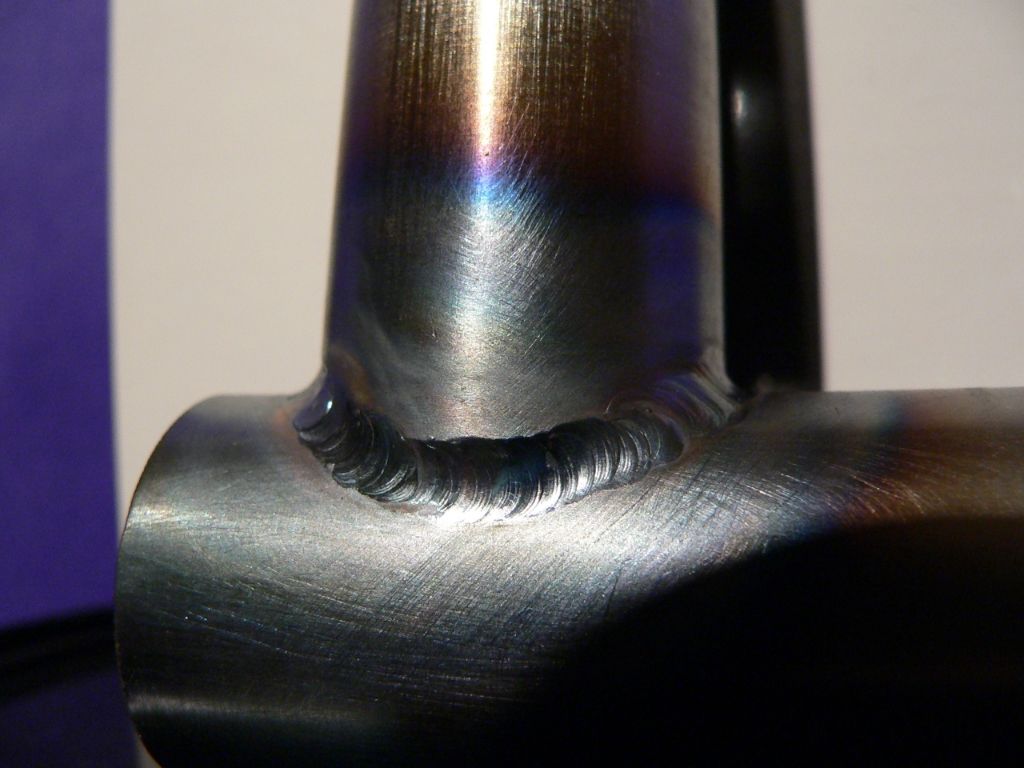

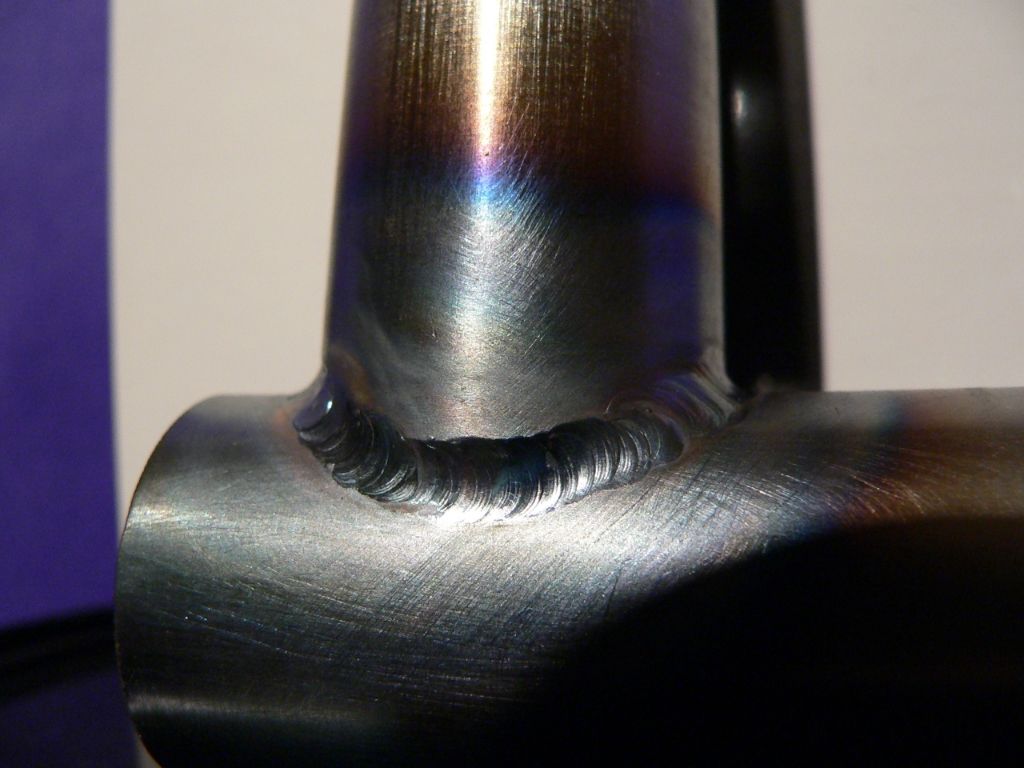

undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 1:02 am

by jcw

Jody makes mention of this in one of his videos and I was wondering if anyone could shed more light on this.

Practicing to weld mild steel tube for motorcycle frame bracing.

1 1/8" tube, 0.065" wall

60amps DC, 1/16" 2% lanth, 0.035 filler, no pulse, #6 gas lens, 15 cfm 100% argon

Along the side of the bottom tube, I'm getting this amount of underfilling or undercutting. Is this unacceptable? or is this an OK weld? or do I have to cut it apart to tell?

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 6:20 pm

by Otto Nobedder

jcw,

I'd call that a "pass" on simple visual inspection. As these are test pieces, though, why NOT cut them apart to see what you can learn?

My thoughts... 60A is hot for .065 wall (at least for me), even if you're moving quick, unless you're using a remote and 60 is just the "max". Also, the low side of the cope naturally requires more material to avoid the underfill appearance, so if you're accustomed to feeding at a fixed rate, as on simple joints, you may have to adjust to feed more often in these low points.

Looking good so far!

Steve S

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 6:30 pm

by jcw

Thanks for the input.

I don't mind getting the thumbs down. I'm still a beginner and learning as much as I can.

Yes, the machine is set at 60 but I'm using the foot pedal and no where near that hot. In fact, I tack at 70, do the high side fillet of the weld at 60 and the low side lap at 50. And still I'm backing off the pedal.

Would a second pass be a good thing to do or should I maybe either go larger filler and/or increase the filler feed. I've tried .045 and 1/16 but the larger the filler rod, the harder it was to melt and it would stick in the puddle. I HATE that.

Don't have a band saw. I wish I did. Maybe time to get a portaband and table.

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 6:49 pm

by Otto Nobedder

I'd try simply increasing the filler feed in the areas that need it... Everything looks great other than that minor underfill, so why screw with what's been working? Just advance in smaller steps and/or feed more often in the areas your practice work seems to need it.

Seriously, you seem to have it, and the welds look perfectly strong to me. Eliminating undercut/underfill in this case is about leaving nothing your customer can question.

I'd still cut a few of the practice pieces apart, just to reassure myself about penetration and overall strength before I sold my welds. I'm sure these will be fine, too, but you'll sleep better seeing it for yourself if you're building motorcycle frames.

Steve S

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 7:00 pm

by danielbuck

just curious, when you want to cut one of these T joints open to look at the welds, what's the best way to go about it? cut it right down the middle (down the T) and then just keep cutting each piece in 1/2 until you're satisfied that it looks good?

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 7:19 pm

by Otto Nobedder

danielbuck wrote:just curious, when you want to cut one of these T joints open to look at the welds, what's the best way to go about it? cut it right down the middle (down the T) and then just keep cutting each piece in 1/2 until you're satisfied that it looks good?

I'd cut it at 45* to the axis of the joint... The tight corners and the long "thumbs" are the areas of least concern. It's the transitions between the two where we're most likely to have challenges.

That said, with several practice pieces to choose from, I'd also disect one at 90*

Steve S

Re: undercutting or underfilling tube joints

Posted: Fri Aug 01, 2014 8:18 pm

by jcw

Got two buckets of practice joints...

- P1070802.JPG (50.19 KiB) Viewed 1881 times

I'm just a hobbyist and don't plan on doing this professionally. I mainly want to make sure I make sound welds on my own motorcycle.

I like tig welding so much, though, I want to be as good as I can at it.

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 4:12 am

by TamJeff

Are you using a dedicated tubing notcher, or cutting these copes by hand?

Welds look decent to me. Nothing beyond hood time if you are pickier.

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 9:06 am

by jcw

I print out the pattern from the tube coping calc on metal geek.com from one of jody's videos.

Grind it on the bench grinder and deburr and fine tune with a bastard file.

I've gotten pretty good and fast at cutting single joints, but i tried tying three tube together and no good.

I'm thinking about either getting a cheap tube notcher i saw on usaweld or setting up my old mini lathe/mill to do this. Not much good for much else.

Any suggestions? Tying into existing frame looks like no fun.

I was thinking about experimenting with pvc pipes to practice first.

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 9:27 am

by Braehill

jcw,

The Harbor Freight tubing notching tool that uses a hole saw works half decent for the price.

Len

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 11:49 am

by GreinTime

I want Baileigh's notcher with the rotary vice!

The only complaint that a lot of people seem to have with the HF ones is the bearings, and you can definitely search "upgraded HF tubing notcher" and probably find part numbers for the pillow block bearings they use.

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 2:04 pm

by TamJeff

Many times, when trying to weld aesthetically, the joint prep can make a difference. With copes, parts of the fitment will have sharp edges and part will be an inside corner and varying degrees of these changes. I have found that when using filler, and not welding these types of joints frequently, sometimes if you blunt the sharp edges creating a lap (or micro-lap of sorts) section, it will be an easier line to follow with an edge that does not burn away, and irregularly as easily as a sharp edge will, allowing you to graduate your heat changes more evenly.

Re: undercutting or underfilling tube joints

Posted: Sat Aug 02, 2014 10:39 pm

by Drifta-X

^^^

I have always thought that would be the case, grind back the sharp/pointy edge so that you actually weld the entire thickness and not just a slither.

Re: undercutting or underfilling tube joints

Posted: Sun Aug 03, 2014 3:45 am

by RichardH

TamJeff, you seem to do a ton of tubing joints - what technique do you use to cope tubing?

As you point out, a hole-saw notcher leaves thin points on two faces. I've wondered about a rotary CNC setup where the cope would stay 90-degrees to the tube, but on an angled joint that'd seem to just move the problem to the inside/outside face.

Cheers,

Richard

Re: undercutting or underfilling tube joints

Posted: Sun Aug 03, 2014 4:32 am

by TamJeff

I use a pro tools notcher for simple copes and use the bandsaw more often than not, mostly because it is half the distance away from my build table than the notcher is. I have developed a good eye for where the center should be at different angles and I can cut them freehand without any lines other than an entry and exit point. Often times, a cope will be right next to a bend so it won't fit into the notcher anyway. If my bandsaw blade starts to get dull, I will use the notcher more often.

But then, I weld mostly aluminum, and aluminum TIG does not mind loose fits. Still, I sand the sharp edges off to a nice land on the stationary belt sander, and it reminds me of the right torch angle as I am going around that portion (think lap joint) and by default, reduces the chance for undercut and makes a nicely rounded sweep that just looks sweeter to my eye.

Re: undercutting or underfilling tube joints

Posted: Sun Aug 03, 2014 7:52 pm

by GreinTime

TamJeff,

Have you looked into the Baileigh notcher that I mentioned? I believe it is a TN-250 maybe?

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 12:59 am

by ONDGAS

Sorry for being a noob...... what is undercutting or under filling ?

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 1:20 am

by TamJeff

GreinTime wrote:TamJeff,

Have you looked into the Baileigh notcher that I mentioned? I believe it is a TN-250 maybe?

Yes. It's similar in principle to the pro tools, hopefully the bearings are better. But what I have issue with is the hole saws, specifically the holes in the sides. It taught me that I can actually stop a Milwaukee 1/2" drill by hand as long as the side handle is installed, when those holes snag the sharp edge of a cope. I would rather switch out the hole saws with annular cutters. For now, I take the hole saws and slightly countersink the critical edge of that hole slightly with a hammer. Others who have not been aware of such things were not so fortunate, because a 1/2" drill can really give one a whuppin, as I am sure here many can agree.

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 3:23 am

by RichardH

ONDGAS wrote:Sorry for being a noob...... what is undercutting or under filling ?

No problem! It's when you don't feed enough filler into a joint, and the heat fills the joint from nearby base metal. The weld will look sunken/concave and base metal at the edge of the weld looks carved out or eaten away.

Cheers,

Richard

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 7:33 am

by ONDGAS

Thanks Richard thats what i thought

Im changing my name to Captain Obvious

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 8:06 am

by RPat

Hello ya'll. I've viewed both of the tools mentioned in this forum topic for possible consideration to purchase to cut tube joints. I'm currently using my drill press along with adjustable clamps to keep the pipe stationary. This works on 1/8" wall aluminum pipe. Anything above that thickness, my press hangs. So I'm wondering if buying these notchers, which appear to be driven by a drill press or possibly a drill would actually improve my current situation? All thoughts/suggestions are welcome.

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 7:11 pm

by GreinTime

Honestly man, I cant say I've ever tried to notch a anything over that thickness. I think it mainly would come down to the HP of your drill (or arm in TamJeff's case

)

TamJeff, in regards to the annular cutters, I was talking with a company at IMIS in Indy 2 years ago, and they were currently doing R&D on deeper throat cutters similar to the Slugger sheet metal hole saws? I think that is the brand I'm thinking of. I will have to see of I can scrounge up a vendor list from the show and figure out who it was.

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 7:27 pm

by Otto Nobedder

In the "EAA Experimenter" magazine, they sell a tool called the "Ol' Joint Jigger", which is designed to do this cope work at all angles on 4130 chromoly tubing at a precision suitable for building airplanes at home.

The precision you need is quite possible, even with less expensive jigs.

Steve S

Re: undercutting or underfilling tube joints

Posted: Mon Aug 04, 2014 10:06 pm

by Legion

RPat, I've got a JD2 Notchmaster. Works well. They sell a bigger notcher that does notches in bends and offsets and stuff. Mine is expandable with some other products from Swag Offroad. I'm sure JD2 list the specs that their notchers are capable of.

Re: undercutting or underfilling tube joints

Posted: Tue Aug 05, 2014 7:34 am

by RPat

Thanks for the recommendations. I've checked out all of your recommendations. Looks like very nice tools. Now to decide which "toy" to go with.