I tried to use my new AHP Alpha tig today and yesterday. No luck. But, I've never tig welded. So, I expected as much. So, this is what I am trying to use.

2# ER4043 Aluminum TIG Welding Rods 2-Lb 3/32" (2.4mm) x 36"

TIG Welding Tungsten Electrodes 2% Lanthanated 3/32" x 7" (Blue, WL20) 10-Pack

TIG Welding Tungsten Electrodes Rare Earth Blend 3/32" x 7" (Purple, EWG) 10-Pack

tig welding rods for steel, which are 3/32.

And a partridge in a pear tree.

I hold the thing over the metal and nothing happens. I mean, I can not get a puddle to start. Once, it burnt a hole through the metal. haha

I realized the metal I am using, is not 1/8. That is what I planned on learning with. I got a 1/8 piece of aluminum. BUT, I thought I would try on metal, to not waste that aluminum piece. But, after thinking, I do not think the metal I am using, is thick enough. It is much smaller than 1/8. I mean, I could fit three or four pieces on top of one another, to be as thick as the 1/8 aluminum. Could that be the problem?

Mind you, I know nothing about tig welding. I set the start amps to like 25. I set the main amps to that as well and the ending amps at like 120. I've no clue about AC freq. I set that at different settings. I did the same for the AC balance. For the post flow, I set it at like 15.

So, first, I just have the tip of the tungsten out. I watched a video on youtube and realized it had to be out more. It is now. I can see the light and I hold it right over the metal. SOMETIMES, I do see a puddle. But, then the arc stops. I am not trying to put the other rod of stuff into the puddle. I am simply trying to get used to starting a puddle and continuing it for a bit. My neighbor was there one. He told me to try the tig rod. I did. It left like, a ball in the other puddle. That seems to me, to mean that the temp was not high enough. Am I wrong? I am going to just say screw it, and try the aluminum tomorrow.

Also, I turn the gas all the way up. There is a nob on the gas thing, I pressed the foot pedal and the ball went all the way to the top. I turned that nob down and the ball was at 20. Then, I tried to tig. It is odd to me. What would cause me to not be able to get a puddle going? I hold the thing right over the metal. Not a thing happens. I have the AHP, hooked to a Bobcat 250. It should be noted, until I make the thing that I need, the AHP is plugged in with the adapter, which cuts the amps down to 100 something. But, should I not still be able to get something going, on 1/8 aluminum or less than 1/8 steel?

I love this site. I look very forward to seeing what those who know, have to say. I wish someone lived in Maryland and could come over and show me what the heck to do. I am a fast learner. haha

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Tom Osselton

- Tom Osselton

-

Workhorse

-

Posts:

-

Joined:Sat Aug 15, 2015 12:33 am

-

Location:Calgary Alberta

Like the others a stop in the tig section of Jody's videos will help you get started.

Sounds you have some 16g or 18g steel, not ideal to learn on. Go to Lowe's and grab at least a 1/8" thick piece of steel, GRIND till it's shiny. Try 60amps and try to just run an autogenous bead (no filler), gas flow at 15-20cfh is fine, welder should be in DCEN, grounded to your metal table or workpiece. I am not familiar with the AHP but start amps and end amps can be the same for a beginner, 60-120hz is fine. I'd get the steel down first before heading to the aluminum....you'll need more then 100amps to puddle your alum piece unless you really preheat it with a torch.

You still going to take the class at Earl Beck? When does that start?

Sounds you have some 16g or 18g steel, not ideal to learn on. Go to Lowe's and grab at least a 1/8" thick piece of steel, GRIND till it's shiny. Try 60amps and try to just run an autogenous bead (no filler), gas flow at 15-20cfh is fine, welder should be in DCEN, grounded to your metal table or workpiece. I am not familiar with the AHP but start amps and end amps can be the same for a beginner, 60-120hz is fine. I'd get the steel down first before heading to the aluminum....you'll need more then 100amps to puddle your alum piece unless you really preheat it with a torch.

You still going to take the class at Earl Beck? When does that start?

Last edited by Rick_H on Mon Sep 19, 2016 2:52 pm, edited 1 time in total.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Well, haha now that I've gotten a Tig welder, I think classes would be good. I've no clue when they start. Even when it says they start in the site, it all depends on how many sign up. I'll get in that tomorrow.

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

As you can see, haha, no luck. It went well at first. Then, I went in and ate dinner and not a thing worked.

I thought I had dust in my glasses and or helmet. I took them off, only to realize that it was almost dark out.

When I went back out, I could not get a puddle at all. I was standing up. Then, I sat and my gun kept falling on my table, thus ruining the thing inside of it. I went through like 5 of those things.

I am not ging to do it tomorrow. It is supposed to rain.

I thought I had dust in my glasses and or helmet. I took them off, only to realize that it was almost dark out.

When I went back out, I could not get a puddle at all. I was standing up. Then, I sat and my gun kept falling on my table, thus ruining the thing inside of it. I went through like 5 of those things.

I am not ging to do it tomorrow. It is supposed to rain.

- Attachments

-

- thumb_IMG_0190_1024.jpg (46.51 KiB) Viewed 2538 times

-

- thumb_IMG_0189_1024.jpg (42.28 KiB) Viewed 2538 times

-

- thumb_IMG_0188_1024.jpg (44.42 KiB) Viewed 2538 times

-

- thumb_IMG_0186_1024.jpg (53.86 KiB) Viewed 2538 times

-

- thumb_IMG_0187_1024.jpg (55.53 KiB) Viewed 2538 times

you have massive amounts of atmospheric contamination and/or you are trying to weld with a contaminated or improperly prepped tungsten.

Also, do not "sand" metal until it's shiny. GRIND it until it's shiny.

Watch every single video on the welding tips and tricks channel on you tube. Even if it's MIG or tig welding. By the time you're done, you'll know what to do. If you dont, then you need serious help, lol.

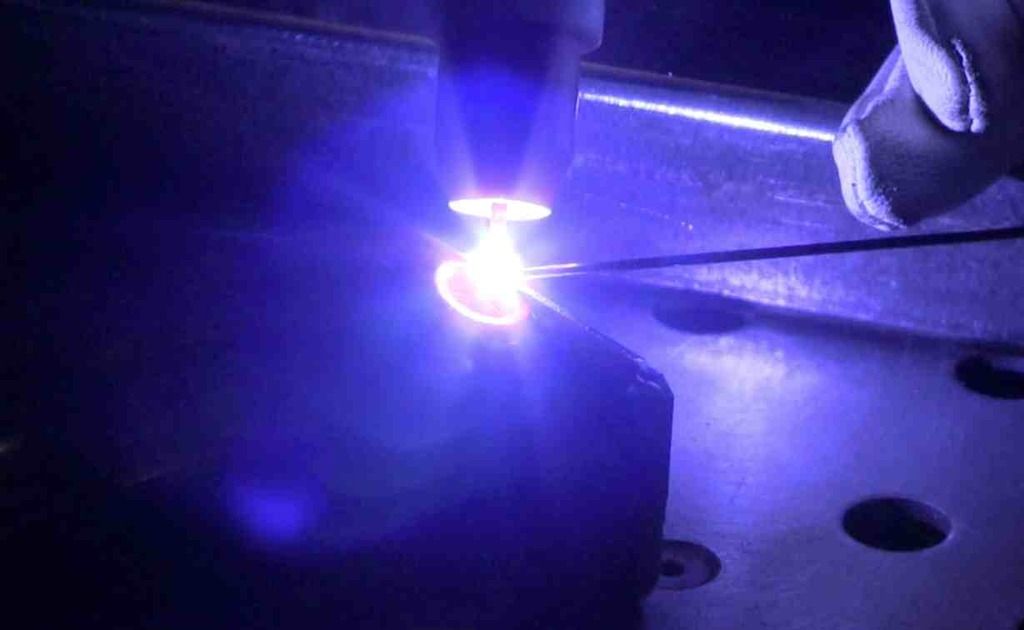

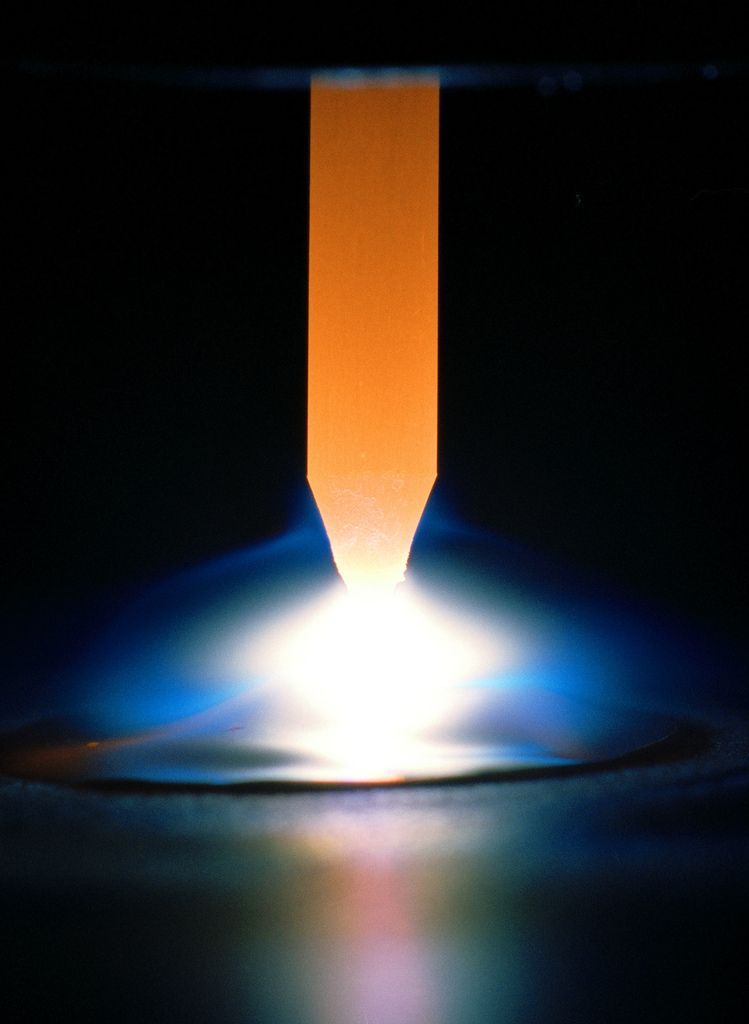

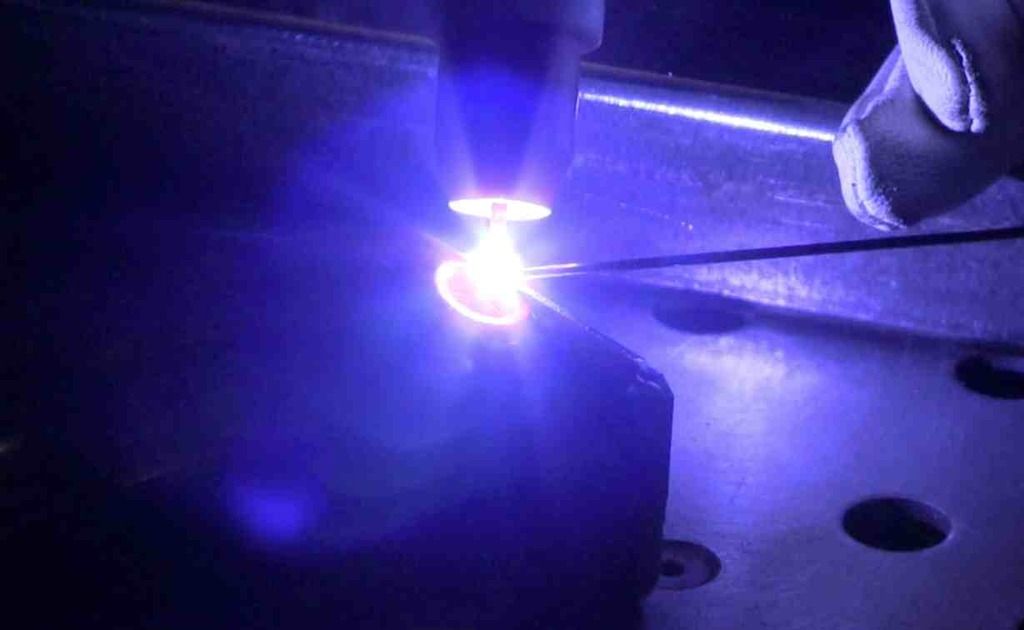

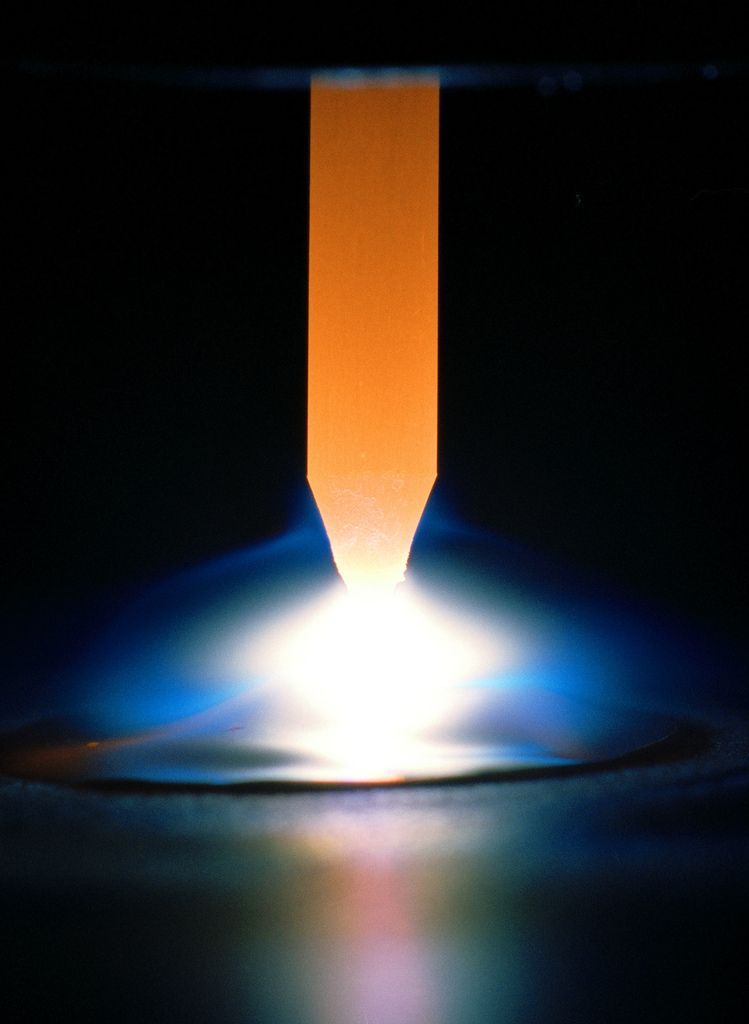

Btw, I hope you can see the arc and the puddle separately through a good lens. Can you see the puddle similar to this:

Or like this?

It should be like the second one. Make sure your lens is new, scratch free, and your eyes are within 8-12" of the arc. Don't even worry about joining two pieces of steel or aluminum together right now. You need to learn how the tig welding process works and how your machine works. You literally need to start from square 1.

Also, do not "sand" metal until it's shiny. GRIND it until it's shiny.

Watch every single video on the welding tips and tricks channel on you tube. Even if it's MIG or tig welding. By the time you're done, you'll know what to do. If you dont, then you need serious help, lol.

Btw, I hope you can see the arc and the puddle separately through a good lens. Can you see the puddle similar to this:

Or like this?

It should be like the second one. Make sure your lens is new, scratch free, and your eyes are within 8-12" of the arc. Don't even worry about joining two pieces of steel or aluminum together right now. You need to learn how the tig welding process works and how your machine works. You literally need to start from square 1.

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Ok, that is helpful stuff. It is odd. I sharpened all my things with a grinder I got from Harbor Freight. Nothing has even been on the grinder before. I could tell something was up. The arc never looks straight. It is like, all over the place.

I know I should not have tired two pieces. But, they were there. haha

I just wrote this on word. I will post it here.

Alright, in sleepy mode. I don’t feel like watching a bunch of welding stuff, until midnight tonight. I have a movie and Simpsons to watch. Haha

Two things I wanted to say about the tig welding thing. I noticed them and thought they may be important. Would the post flow being too high, make either of these happen?

First, when I take my foot off of the pedal, that comes with the AHP Alpha tig, the weld does not stop. I mean, I held the thing there for a while, until I just had to pull it away. Should it not have stopped? Maybe the post flow is too high? MAYBE, the starting amps are up too much?

Then, when I bled the line, (if that is what it is called) to get the extra argon out of the line, I had to hit the foot pedal, like 4 – 6 times, before the ball would not go up to 15 or 20. Why would that happen? Is it normal for that much argon to be in the line?

I know I should not have tired two pieces. But, they were there. haha

I just wrote this on word. I will post it here.

Alright, in sleepy mode. I don’t feel like watching a bunch of welding stuff, until midnight tonight. I have a movie and Simpsons to watch. Haha

Two things I wanted to say about the tig welding thing. I noticed them and thought they may be important. Would the post flow being too high, make either of these happen?

First, when I take my foot off of the pedal, that comes with the AHP Alpha tig, the weld does not stop. I mean, I held the thing there for a while, until I just had to pull it away. Should it not have stopped? Maybe the post flow is too high? MAYBE, the starting amps are up too much?

Then, when I bled the line, (if that is what it is called) to get the extra argon out of the line, I had to hit the foot pedal, like 4 – 6 times, before the ball would not go up to 15 or 20. Why would that happen? Is it normal for that much argon to be in the line?

- entity-unknown

-

Ace

-

Posts:

-

Joined:Mon Jul 18, 2016 2:07 pm

-

Location:Mesa, AZ

Too much post flow time will never hurt. Too much post flow pressure will. I've been getting away with 8CFH with aluminum, steel, and stainless without much issue but I am using a gas lens. I even had a normal setup and had no problems but I think atmospheric conditions can have an effect. Basically 8-15 CFH is usually perfect. I've heard 20 is getting close to bein too high unless you have like a #10 or bigger cup. I'm gonna guess that if you can feel a breeze of gas coming out, it's too much. If you can feel a gentle blow then you're probably fine. Don't point it at your face to feel it

As for clipping your tungsten, I personally would not do it but if you're a perfectionist and/or want to remove any possibility of contamination playing a role, clip it. If you're moving up to food grade welding or doing welds that will have someone's life in the balance then clip every time. This is an experience/personal preference thing to me

Now if your machine continues to run the arc after releasing the pedal then you've got a pedal problem. If your gas just continues to run then that's post flow and all is well. Seriously though, if your arc continues after releasing the pedal, do not weld anymore until you get that replaced. Your home, possessions, (family?), and life are more important than practice and that is not something to wing it with. If it's a new welder with a warranty, get it replaced. If there's no warranty then I'd say now is a wonderful time to get your self a fancy SSC pedal. You can contact SSC and tell them your machine and build year and they'll likely have the correct pin out and connector. I'm VERY pleased with my new SSC and have yet to read a single complaint about them.

As for clipping your tungsten, I personally would not do it but if you're a perfectionist and/or want to remove any possibility of contamination playing a role, clip it. If you're moving up to food grade welding or doing welds that will have someone's life in the balance then clip every time. This is an experience/personal preference thing to me

Now if your machine continues to run the arc after releasing the pedal then you've got a pedal problem. If your gas just continues to run then that's post flow and all is well. Seriously though, if your arc continues after releasing the pedal, do not weld anymore until you get that replaced. Your home, possessions, (family?), and life are more important than practice and that is not something to wing it with. If it's a new welder with a warranty, get it replaced. If there's no warranty then I'd say now is a wonderful time to get your self a fancy SSC pedal. You can contact SSC and tell them your machine and build year and they'll likely have the correct pin out and connector. I'm VERY pleased with my new SSC and have yet to read a single complaint about them.

Lincoln Electric AC225

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

i do not know what the features and setting are on a alpha welder

are but one day i inadvertently hit the 4t button on my hpt 221

(torch switch setting) while using a foot pedal. the arc continued

to stay lit after releasing the pedal. food for thought.

craig

are but one day i inadvertently hit the 4t button on my hpt 221

(torch switch setting) while using a foot pedal. the arc continued

to stay lit after releasing the pedal. food for thought.

craig

htp invertig 221

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

- entity-unknown

-

Ace

-

Posts:

-

Joined:Mon Jul 18, 2016 2:07 pm

-

Location:Mesa, AZ

Craig probably has it! And now I sound like the guy blaming the transmission for a tire problem

Lincoln Electric AC225

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Jim FLinchbaugh

- Jim FLinchbaugh

-

Workhorse

-

Posts:

-

Joined:Thu Sep 01, 2016 11:56 pm

-

Location:Kalispell Montana

I'm betting this, they say NOT to use the 4t setting with the foot pedal, which means it is likely possible tomotox wrote:i do not know what the features and setting are on a alpha welder

are but one day i inadvertently hit the 4t button on my hpt 221

(torch switch setting) while using a foot pedal. the arc continued

to stay lit after releasing the pedal. food for thought.

craig

have 4t active with the pedal, even though it shouldnt be.

Glow-

If I read your post right, sounds like you might be welding outside?

Do not do that, the wind will carry off the argon and mess with you big time

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Cool, well, it has a 5 year warranty. But, I had no luck when I first ordered from AHP. That is why I canceled and got it from Amazon. Not at all worth returning for the pedal. I found a place that had one for the 2015 and 2016 version for like, $175. I will just get that. They also have a tig torch stand that I think would be rather useful.

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Oh, I just read the no outside thing. haha I have no choice. I can not weld in the shed thing I have. It is to small. There was no wind yesterday. But, it was cloudy. Also, I believe I had the machine set to 4t.

This site makes it easy to learn stuff. I would say before, that I knew not a person who welded. Now, I can say I know any number. haha Great site, cool people. WELDING!

This site makes it easy to learn stuff. I would say before, that I knew not a person who welded. Now, I can say I know any number. haha Great site, cool people. WELDING!

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

I just read something else. Wow, I am sloooow today. I believe I have the thing set to 4t. LOL All good stuff. I shall fix. It is raining now. It's good. I have to exercise. Plus, I have 10 minutes left from yesterday, that I did for my brothers wedding and and 44 minutes extra to do for Friday when the rehearsal is. haha I like having things done. I am weird that way.

That course as a new welder will be very beneficial to you and teach you the right way to start out, look at the right things. The beginner class does SMAW, GMAW, TGAW, oxy acetylene welding and cutting, and plasma, plus gives you some PPE....good for your Bobcat and AHP.Glowzinski wrote:Well, haha now that I've gotten a Tig welder, I think classes would be good. I've no clue when they start. Even when it says they start in the site, it all depends on how many sign up. I'll get in that tomorrow.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

- entity-unknown

-

Ace

-

Posts:

-

Joined:Mon Jul 18, 2016 2:07 pm

-

Location:Mesa, AZ

Yeah if you have it at 4T you will have all sorts of problems. Since it was on, I'd assume your welder and pedal are probably fine, just an operator/settings issue. Don't feel bad everyone was guilty for at least one bad setting in their TIG life  If you haven't spent an evening reading every page in your manual, now would be a great time too

If you haven't spent an evening reading every page in your manual, now would be a great time too

I know with my Everlast even on 2T/Pedal I must set the up/down slope to 0 otherwise you get weird behavior when using the pedal. If not using the pedal then you'll have the bonus of having the up/down slopes but you probably wanna figure out what you find works for you in regards to Amps and travel speed then you can start playin with all those fancy features.

If you're stuck outside, then you might consider a 10x10 gazebo. Walmart has the Coleman one which I've had for about 8 years and it works great. Harbor Freight has one too and with those 20% off coupons, it could make it worth while. You CAN set it up with a single person but it takes a bit and you have to walk around and move one leg out just a bit at a time or you'll twist the frame. It cost me about $80 and I bought the Coleman side walls for about $15 for each wall. You can just but tarps for the sides which will be cheaper but you don't get the fancy clips but it's not a big deal. Alternatively you can put yourself against a wall and wall yourself off with a creative tarp setup.

If you ever see rust on steel, yellow on aluminum, or black sugar on stainless steel appear immediately when you start TIG'in you've got gas issues and if you have the bottle on, Argon in the bottle, and at least 8CFH, then chances are it's ambient air flow, not a machine/bottle flow issue. I have my cheapo box fan running sometimes down below my table and haven't had an issue but I'm pretty sure if I aimed it up, things would not go well but I'm also in a garage. When you're outside there is always air movement even if there is "no wind". That's just how our Earth works

I wanted the TIG torch stand I'm sure you're looking at but I decided to hang a bungee cord from my ceiling and I just hang the torch leads/sleeve in the bungee hook with enough lead so the torch hangs above the ground but still has enough to grab the torch and do my job. If I drop the torch, it doesn't hit the ground either plus it takes all the cable weight so you don't have to set it across your lap, neck, or in your arm pit.

Have fun and keep on TIG'in!

P.S. all your issues thus far; I've had every single one plus many more and so has almost everyone else at one point probably so you're not alone

I know with my Everlast even on 2T/Pedal I must set the up/down slope to 0 otherwise you get weird behavior when using the pedal. If not using the pedal then you'll have the bonus of having the up/down slopes but you probably wanna figure out what you find works for you in regards to Amps and travel speed then you can start playin with all those fancy features.

If you're stuck outside, then you might consider a 10x10 gazebo. Walmart has the Coleman one which I've had for about 8 years and it works great. Harbor Freight has one too and with those 20% off coupons, it could make it worth while. You CAN set it up with a single person but it takes a bit and you have to walk around and move one leg out just a bit at a time or you'll twist the frame. It cost me about $80 and I bought the Coleman side walls for about $15 for each wall. You can just but tarps for the sides which will be cheaper but you don't get the fancy clips but it's not a big deal. Alternatively you can put yourself against a wall and wall yourself off with a creative tarp setup.

If you ever see rust on steel, yellow on aluminum, or black sugar on stainless steel appear immediately when you start TIG'in you've got gas issues and if you have the bottle on, Argon in the bottle, and at least 8CFH, then chances are it's ambient air flow, not a machine/bottle flow issue. I have my cheapo box fan running sometimes down below my table and haven't had an issue but I'm pretty sure if I aimed it up, things would not go well but I'm also in a garage. When you're outside there is always air movement even if there is "no wind". That's just how our Earth works

I wanted the TIG torch stand I'm sure you're looking at but I decided to hang a bungee cord from my ceiling and I just hang the torch leads/sleeve in the bungee hook with enough lead so the torch hangs above the ground but still has enough to grab the torch and do my job. If I drop the torch, it doesn't hit the ground either plus it takes all the cable weight so you don't have to set it across your lap, neck, or in your arm pit.

Have fun and keep on TIG'in!

P.S. all your issues thus far; I've had every single one plus many more and so has almost everyone else at one point probably so you're not alone

Lincoln Electric AC225

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Yea long story short you have it on 4T and not 2T. That's why watching videos will undoubtedly get you on the right track the quickest. But you will also pick up so much more, you will learn what other settings do, which you need to know before you just randomly and blindly start turning knobs. You'd be making it that much more difficult for us to help if you if you don't know what you did, because you won't know or will be mixed up with the terminology that you could have straightened out before-hand.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Rip the knobs off the thing and set your amperage, cfh , AC or DC, tungsten size and weld. Skip the bells and whistles...permanently if you can.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

Bells and whistles are another tool in the bag after you have a thorough understanding of what your doing. Guys at my work ask why I adjust frequency on aluminum, and play with high speed pulse on stainless and stuff like that. I sit my part next to theirs and say "I welded that gap in one pass, with minimal trouble. You didn't hear me yelling and bitching over there like you were." Cut one aluminum weld apart that gets ground down flush and you can instantly see what kind of difference in penetration you get with varying frequencies.exnailpounder wrote:Rip the knobs off the thing and set your amperage, cfh , AC or DC, tungsten size and weld. Skip the bells and whistles...permanently if you can.

Features, in and of themselves, are not a bad thing. For the novice welder, having so many knobs to turn leads to situations like this. For the guy who understands what he's doing, and has progressed to the point that he can actually weld, they can work wonders.

For the record, I find that most of the old heads in the shop refuse to listen, and should be welding with the syncrowave instead of the Dynasty that they have in their booth. Some of them are keen to learn new tricks, other, not so much. I had a 20 minute discussion about the benefits of a gas lens (and bigger cups, like the TiCup and the Furick Cups) versus a regular collet body on stainless like he's using now. I think I've finally convinced him to try the gas lens.

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

My machine has 'dummies' settings for both AC and DC.

You select the setting, adjust your post flow....that's it. Go weld. When I first started out it was a life saver. It's so good to just be able to do some welding without getting caught up in all the settings.

After a week or two of that, I dove into the details and functions of my machine and now I never almost use the 'dummies' settings.

There's certainly a lot to be said for sticking to the basics when you first start out, but after you get some seat time, the deeper capabilities of the machine will draw you in for sure. In particular,pulse was an eye-opener for me.

Kym

You select the setting, adjust your post flow....that's it. Go weld. When I first started out it was a life saver. It's so good to just be able to do some welding without getting caught up in all the settings.

After a week or two of that, I dove into the details and functions of my machine and now I never almost use the 'dummies' settings.

There's certainly a lot to be said for sticking to the basics when you first start out, but after you get some seat time, the deeper capabilities of the machine will draw you in for sure. In particular,pulse was an eye-opener for me.

Kym

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

I digress...I probably shouldn't have said to lose the bells and whistles permanently. I don't have many on my machine but I do use pulse to keep down the heat on SS. I guess what I meant to say was to learn to weld before playing with the knobs and making an already skill intensive task even harder by getting ahead of yourself. I can understand the zeal of wanting to get the tig thing down as fast as possible but we learn to crawl before we walk. I am an old-school hard head myself sometimes. My friend is a pipe welder and he uses scratch start all the time. He came over to use my machine and acted like he never saw a foot pedal before much less ever used one and I have seen his pipe welds and they are amazing. I just think that some might use the features on their machines as a crutch rather than learn to weld the right way. I also think that when people watch Jody weld, he makes it look so easy and he talks about and uses features on different machines and that might lead someone into thinking that the features make the welds for them. I think Jody could do a beautiful weld with a car battery, jumper cables and a coat hanger.

Last edited by exnailpounder on Tue Sep 20, 2016 3:51 pm, edited 1 time in total.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

jeff makes a good point about bells and whistles. like any

tool you own you must first master using it then your abilities and

patients will dictate how well you progress with it..

craig

tool you own you must first master using it then your abilities and

patients will dictate how well you progress with it..

craig

htp invertig 221

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

Glowzinski

- Glowzinski

-

Guide

-

Posts:

-

Joined:Thu Dec 31, 2015 9:08 pm

-

Location:Maryland

Yes, I don't care about all the stuff right now. However, I do need to know what to set the stuff on. I suppose that is trial and error. I ordered a book today. It was a penny. haha Gas Tungsten Arc Welding Handbook. So, I will see what I learn from that.

So, these are pictures of what I tried today. It seems like I did get something going. BUT, should the puddles not be larger than this? LOL I have the size 5 thing on the gun. If I changed that, would it make a difference, or is it a setting on the machine that would?

So, these are pictures of what I tried today. It seems like I did get something going. BUT, should the puddles not be larger than this? LOL I have the size 5 thing on the gun. If I changed that, would it make a difference, or is it a setting on the machine that would?

- Attachments

-

- IMG_0216.jpg (93.07 KiB) Viewed 2435 times

-

- IMG_0215.jpg (49.05 KiB) Viewed 2435 times

-

- IMG_0214.jpg (90.79 KiB) Viewed 2435 times

Miller used to offer a good TIG handbook for free, now they sell it for $25. I have the full handbook on my Google drive that you can download. https://drive.google.com/file/d/0BzZ5Fs ... p=drivesdk

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities