My next weld, tomorrow, I had to actually grind in the mirror.

I tried to set up a platform I could lay on, but it didn't allow me any vision to the repair I'm making.

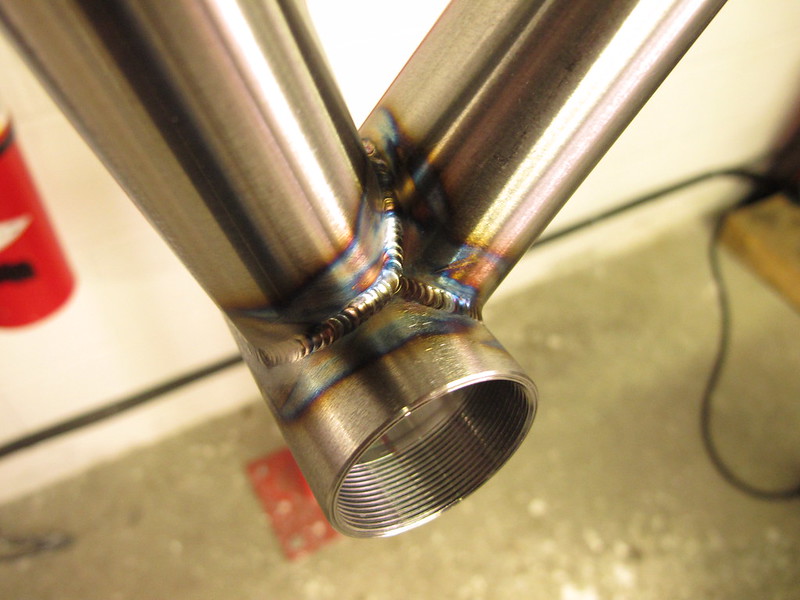

Here's a few pics:

- GEDC0831.JPG (204.42 KiB) Viewed 6388 times

This is general location, with the useless platform in place. The green tape with the arrow shows where the leak is, sort-of. It's up under, as in "stand on your head".

Here's the leak, shown in dye-penetrant, with the gusset it was under sectioned out:

- GEDC0834.JPG (190.35 KiB) Viewed 6388 times

And here it is, ground nearly through 1/2" of 304SS, reduced to it's origin:

- GEDC0838.JPG (172.53 KiB) Viewed 6388 times

Note the mirror... I had to grind it in the mirror, so there's no doubt I'll have to weld it the same way. Tomorrow should be interesting!

Steve S