Yeah very expensive... Most won't spend the $$ on it, but it sure is pretty! Truth be told it was for an import..lol Last I bought it through SPD, I think Burns sells it alsoGreinTime wrote:321 is so fucking expensive though.Rick_H wrote:316 welds very similar to all of those, I've used 321 and 347 filler with headers in the past. The cage looks good, I'll have to dig up some pics from my 25.5 SFI chassis I put in my 91 Mustang GT. Funny I look at those welds now and say man I can do better.AFR_Autoworks wrote:How is 316 to weld? Much different then 304? Never done any 316. In my line of work I will likely never use it, 304 and 321 are all us car guys really use.

With food stuff it is a lot of 316L and 304.

Sent from my SM-G900V using Tapatalk

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

AFR_Autoworks

- AFR_Autoworks

-

Workhorse

-

Posts:

-

Joined:Mon Nov 30, 2015 2:35 am

-

Location:Red Deer, Alberta, Canada

Yes 321 is very pricey but is the best choice for any sort of turbo application where exhaust will be subject to allot of heat. If you have ever seen a turbo manifold on a 1000hp car, it gets pretty crazy haha.

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

I understand that lol, but it is outside the budget realm for most people turboing their Honda CivicAFR_Autoworks wrote:Yes 321 is very pricey but is the best choice for any sort of turbo application where exhaust will be subject to allot of heat. If you have ever seen a turbo manifold on a 1000hp car, it gets pretty crazy haha.

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

Aaron

just tried your setting..

worked well. I'm hooked...

for all the guys that don't weld every day

remember this "TIG FINGER"

just welded this today.

pencil mark was how far i got

before my hand was fried.

use the TIG finger...lol

craig

just tried your setting..

worked well. I'm hooked...

for all the guys that don't weld every day

remember this "TIG FINGER"

just welded this today.

pencil mark was how far i got

before my hand was fried.

use the TIG finger...lol

craig

- Attachments

-

- IMG_2539 alum finger.jpg (87.78 KiB) Viewed 1694 times

htp invertig 221

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

(The flower thing in its entirety)

(Grinded and ready to weld)

(Finished.)

G'day.

In amongst all the inspiring aerospace/automotive stuff on here, (which I absolutely love!) I like to post now and then to represent the noobs out there like me, who are still scratching their heads and banging rocks together.

Was given this very hipster lawn ornament/drink holder thing to fix. It's very old. The thin metal 'flower' had broken from the much thicker 'stem'. The brief was to fix it, make it sturdy, not do too much damage to 'vintage' paint.

Used 35 amps, very sharp 1.6mm electrode (2% Lanth) and 1.2mm ER316SL filler because it's the thinnest I have. Took it slow, lit up on the 'stem' and worked around. Stop. Cool. Clean. Weld. Only really took out a patch of paint the size of a 50 cent piece.

Now my hipster mate can enjoy Pickle Backs out on the lawn again...

Kym

Wanted to get more building done today, but email and phone calls had to take priority. At least I got half a bike done.

0210161113_HDR by Mike Zanconato, on Flickr

0210161112_HDR by Mike Zanconato, on Flickr

0210161113a_HDR by Mike Zanconato, on Flickr

0210161113_HDR by Mike Zanconato, on Flickr

0210161112_HDR by Mike Zanconato, on Flickr

0210161113a_HDR by Mike Zanconato, on Flickr

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Aaron do you use a standard Aluminum Oxide wheel or a diamond wheel? If a Diamond wheel what grit is it?Aaron@6061.com wrote:I chuck my tungsten in a handheld drill and spin it as slow as possible while grinding it to shape on a bench grinder with a 6" wheel.

Thanks

Brian

Brian

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Thanks guys!

Machine set at 210 amps EP, 180 amps EN, 65-75% EN balance, frequency at 120-150 Hz, soft square wave on EP and EN.

Torch is a CK20 with a gas lens and #8 cup. Gas at 15-20 cfh. 3/32" 2% lanthanated tungsten ground to a point.Hollywood1 wrote:Bike frame looks great! Any tips on welder settings?

Machine set at 210 amps EP, 180 amps EN, 65-75% EN balance, frequency at 120-150 Hz, soft square wave on EP and EN.

Nice work Kym! Being a fellow noob I appreciate where you are coming from.MosquitoMoto wrote:In amongst all the inspiring aerospace/automotive stuff on here, (which I absolutely love!) I like to post now and then to represent the noobs out there like me, who are still scratching their heads and banging rocks together.

As always, love your work Mike!zank wrote:Wanted to get more building done today, but email and phone calls had to take priority. At least I got half a bike done.

Flo

What grade of aluminum are the frames, and what is the wall thickness?zank wrote:Thanks guys!

Torch is a CK20 with a gas lens and #8 cup. Gas at 15-20 cfh. 3/32" 2% lanthanated tungsten ground to a point.Hollywood1 wrote:Bike frame looks great! Any tips on welder settings?

Machine set at 210 amps EP, 180 amps EN, 65-75% EN balance, frequency at 120-150 Hz, soft square wave on EP and EN.

Thanks

Brian

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Thanks for the info. I am using the same torch with a gas lense. When I start practice on aluminum I'll have a place to start with settings.zank wrote:The tubing is 7005 aluminum. The head tube and threaded shell are 0.160" wall and the other tubes range from 0.052" - 0.078" wall.

Filler is 3/32" 5183.

Brian

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

100 grit 6" aluminum oxidemelsdad wrote:Aaron do you use a standard Aluminum Oxide wheel or a diamond wheel? If a Diamond wheel what grit is it?Aaron@6061.com wrote:I chuck my tungsten in a handheld drill and spin it as slow as possible while grinding it to shape on a bench grinder with a 6" wheel.

Thanks

Brian

- AKweldshop

-

Weldmonger

-

Posts:

-

Joined:Wed Oct 23, 2013 3:30 pm

-

Location:Palmer AK

MosquitoMoto wrote:Beautiful work, Aaron.

Kym

Beautiful doesn't even begin to describe it....

Just a couple welders and a couple of big hammers and torches.

Men in dirty jeans built this country, while men in clean suits have destroyed it.

Trump/Carson 2016-2024

Men in dirty jeans built this country, while men in clean suits have destroyed it.

Trump/Carson 2016-2024

Thanks Aaron!!Aaron@6061.com wrote:100 grit 6" aluminum oxidemelsdad wrote:Aaron do you use a standard Aluminum Oxide wheel or a diamond wheel? If a Diamond wheel what grit is it?Aaron@6061.com wrote:I chuck my tungsten in a handheld drill and spin it as slow as possible while grinding it to shape on a bench grinder with a 6" wheel.

Thanks

Brian

Brian

Brian

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

- big gear head

-

Ace

-

Posts:

-

Joined:Thu May 07, 2015 11:46 am

-

Location:KY.

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

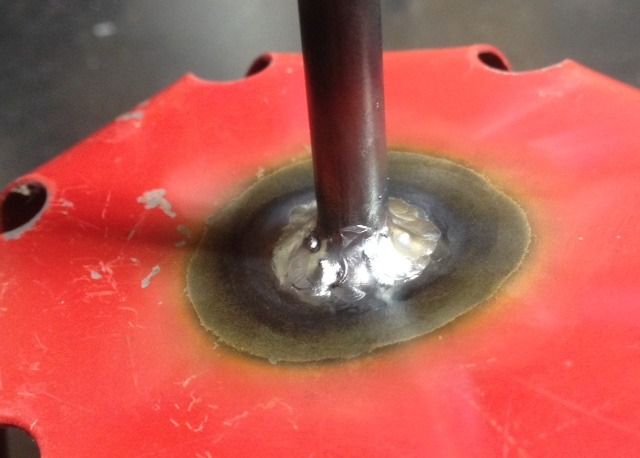

1/2" 316L Sanitary piping, full pen, back purge, yadda, yadda

- Attachments

-

- IMG_20160214_242025287.jpg (50.92 KiB) Viewed 1586 times

-

- IMG_20160213_230649742_HDR.jpg (80.79 KiB) Viewed 1586 times

-

- Inside

- IMG_20160213_232408005_HDR.jpg (52.83 KiB) Viewed 1586 times

-

- Heres the entire section, made to fit around a piece of existing framing

- IMG_20160213_211602410_HDR[1].jpg (49.04 KiB) Viewed 1613 times

-

- all pickled and polished

- IMG_20160213_205532062[1].jpg (50.06 KiB) Viewed 1613 times

-

- raw....

- IMG_20160213_202722178[1].jpg (74.5 KiB) Viewed 1613 times

Last edited by Rick_H on Sun Feb 14, 2016 1:22 am, edited 1 time in total.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

Aaron, beautiful, looks like a FORD

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities