Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

Advancedynamix

- Advancedynamix

-

New Member

-

Posts:

-

Joined:Thu Aug 06, 2015 4:56 pm

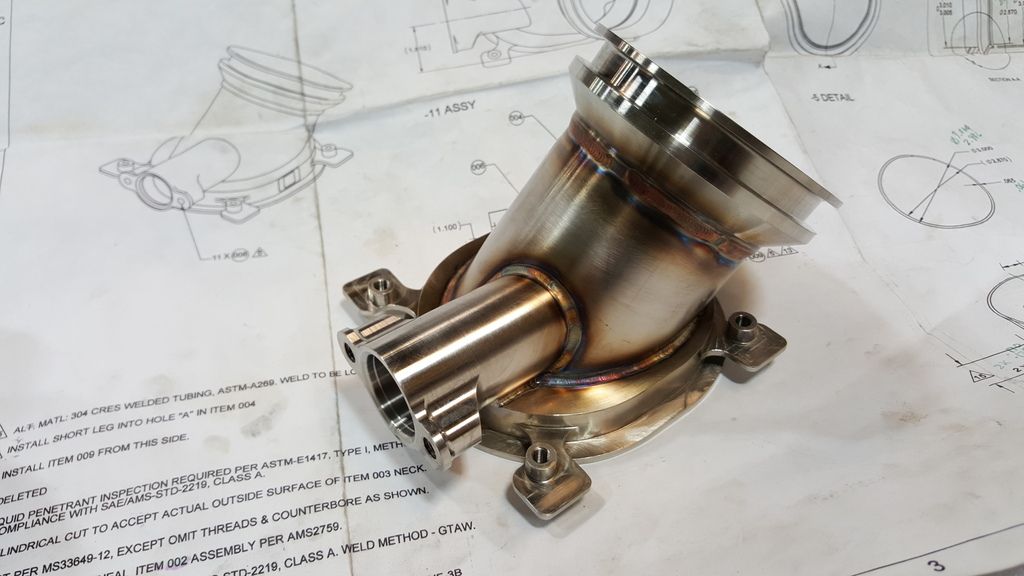

Thanks! Most of the parts I build are for flight, so that's common. It's nice to find folks who can point that out. Many years of practice (and a few grey hairs, lol) to not sweat class A NDT.

This is a piece of art work! I would throw my wife's flower arrangement off the dining room table and use this as a centerpiece...

Brian

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Miller Thunderbolt 225 AC/DC

Everlast 255EXT with W300 cooler

Hobo Freight 170 MIG Welder

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Welded some more on roll cage. Lots of people wanting work done. Thanks John.

- Attachments

-

- 20160204_163654.jpg (41.07 KiB) Viewed 1671 times

-

- 20160204_164803.jpg (269.87 KiB) Viewed 1671 times

-

- 20160204_162449.jpg (55.06 KiB) Viewed 1671 times

- big gear head

-

Ace

-

Posts:

-

Joined:Thu May 07, 2015 11:46 am

-

Location:KY.

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Backsheddave

- Backsheddave

-

New Member

-

Posts:

-

Joined:Sat Jul 19, 2014 4:46 am

-

Location:New Zealand

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

Yep... Miller bought the marketing rights to the Servore goggles about a year ago.Oscar wrote:Are those the Miller or Sevore glasses? Probably one and the same thingHollywood1 wrote:Welded some more on roll cage. Lots of people wanting work done. Thanks John.

Steve S

AFR_Autoworks

- AFR_Autoworks

-

Workhorse

-

Posts:

-

Joined:Mon Nov 30, 2015 2:35 am

-

Location:Red Deer, Alberta, Canada

My latest roll cage. So much time goes into fitting each and every piece. I will say, proper fitment ensures the best weld (still working on that part haha). I apologize for the sideways pictures. I guess they are like that if I take a picture with my phone tilted... Even though they are the right way on my phone

- Attachments

-

- image.jpeg (59.94 KiB) Viewed 1675 times

-

- image.jpg (53.54 KiB) Viewed 1675 times

-

- image.jpeg (61.93 KiB) Viewed 1675 times

-

- image.jpeg (93.86 KiB) Viewed 1675 times

-

- image.jpeg (36.32 KiB) Viewed 1675 times

- big gear head

-

Ace

-

Posts:

-

Joined:Thu May 07, 2015 11:46 am

-

Location:KY.

Looks good. Is this Mustang going to be a drift car? I've never seen curved top bars like that before.

Freddie

AFR_Autoworks

- AFR_Autoworks

-

Workhorse

-

Posts:

-

Joined:Mon Nov 30, 2015 2:35 am

-

Location:Red Deer, Alberta, Canada

Yes this car will be a drift car. I build most of my drift cages like FIA cages though. I don't think FD cages are sturdy enough.

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

If it passes FIA it should pass anythingAFR_Autoworks wrote:Yes this car will be a drift car. I build most of my drift cages like FIA cages though. I don't think FD cages are sturdy enough.

I would assume you have a radius bender as well as a traditional bender?

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

AFR_Autoworks

- AFR_Autoworks

-

Workhorse

-

Posts:

-

Joined:Mon Nov 30, 2015 2:35 am

-

Location:Red Deer, Alberta, Canada

GreinTime wrote:If it passes FIA it should pass anythingAFR_Autoworks wrote:Yes this car will be a drift car. I build most of my drift cages like FIA cages though. I don't think FD cages are sturdy enough.

I would assume you have a radius bender as well as a traditional bender?

Sent from my SM-G900V using Tapatalk

Yes I have a tubing roller along with a normal tubing bender. This is my first cage using the roller this much. It certainly adds allot to the style of the cage and is really nice for roof bars in cages. It was not cheap but certainly a worth while investment.

Thanks!Hollywood1 wrote:looks good!

1/2" diameter 316L sanitary.... Tricky little stuff..lol

- Attachments

-

- Over all view of custom pieces

- IMG_20160208_233533698.jpg (44.3 KiB) Viewed 1803 times

-

- 1/2" tri clover style fitting

- IMG_20160208_233304180.jpg (39.61 KiB) Viewed 1803 times

-

- 1/2" end cap

- IMG_20160208_233154131.jpg (33.07 KiB) Viewed 1803 times

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

AFR_Autoworks

- AFR_Autoworks

-

Workhorse

-

Posts:

-

Joined:Mon Nov 30, 2015 2:35 am

-

Location:Red Deer, Alberta, Canada

How is 316 to weld? Much different then 304? Never done any 316. In my line of work I will likely never use it, 304 and 321 are all us car guys really use.

Yeah it's all back purged, fit perfectly flat and welded with no filler full penetration.motox wrote:fusion weld?

if not what filler did you use?

craig

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

316 welds very similar to all of those, I've used 321 and 347 filler with headers in the past. The cage looks good, I'll have to dig up some pics from my 25.5 SFI chassis I put in my 91 Mustang GT. Funny I look at those welds now and say man I can do better.AFR_Autoworks wrote:How is 316 to weld? Much different then 304? Never done any 316. In my line of work I will likely never use it, 304 and 321 are all us car guys really use.

With food stuff it is a lot of 316L and 304.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

321 is so fucking expensive though.Rick_H wrote:316 welds very similar to all of those, I've used 321 and 347 filler with headers in the past. The cage looks good, I'll have to dig up some pics from my 25.5 SFI chassis I put in my 91 Mustang GT. Funny I look at those welds now and say man I can do better.AFR_Autoworks wrote:How is 316 to weld? Much different then 304? Never done any 316. In my line of work I will likely never use it, 304 and 321 are all us car guys really use.

With food stuff it is a lot of 316L and 304.

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities