Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

So have been doing more and more titanium. I have done lots of practice and have been able to remedy some little hick ups I have along the way. Well Im at my wits end with this one. settings are as follows. 33 amps, 2 seconds pre flow, 12 seconds post flow, 1/16 lanthanated tungsten, 1.25 inch stick out, #24 cup with 55 cfh flow. Material is .040 and so is the filler. Bottle is at 1300 psi. When I put a #16 cup on the issue is not as bad but still not able to make a sound weld. Everything behaves like my gas is getting blown away but I eliminated and drafts. Tried a newly cleaned filler rod and no change. Everything welds great until I get to the tighter part of the pie cuts. I have never come across this before. PLEASE HELP!!!

- Attachments

-

- tigpie2.jpg (39.29 KiB) Viewed 1195 times

-

- tigpie.jpg (32.89 KiB) Viewed 1195 times

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

For shits and giggles, turn your flow down to 35cfh. Your transitioning from Welding an outside corner shape wise, as the argon is going around the pipe, as well as on either side of the welded joint, to welding in a valley of sorts with the short side. With a flow that high, I wouldn't be surprised if you weren't creating turbulence that is in fact sucking atmosphere in, especially since you are only welding a 45° section (assuming a 4.5/9 cut since they are so thin.) You're not much bigger than 2" across the short side, and if the argon wraps the edges, it will create a swirl as it goes around the edge.

Sent from my VS995 using Tapatalk

Sent from my VS995 using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

I do know that anything below 45 cfh that cup doesn't like it. It's all sorts of issues. But I think you're on to something with turbulence. I think maybe the back purge may be causing the torch flow to go wild. In the first picture all the seams are fully welder all the way around. I'll play with my back purge tomorrow thanks!

Why so long of a stick out? It's not surprising that less than a ginormous amount of flow yielded undesirable results---the stick out has a lot to do with how much (or how little) flow you can get away with. Kill the stickout to 3/8"-1/2" and turn it down to 30-35 CFH. That's what I'd do. I know it will be hard to see the tungsten tip without tilting your head, but try it. Simply keep in mind that the shorter you can keep the stickout, the less argon you need, to an extent though.

I normally have to lean and bend in all kinds of ways to see my Tungsten, I keep it sticking out of the cup by an 1/8" or so unless I am doing fillet welds in corners or something where I can't weld properly with it that short.

if there's a welder, there's a way

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

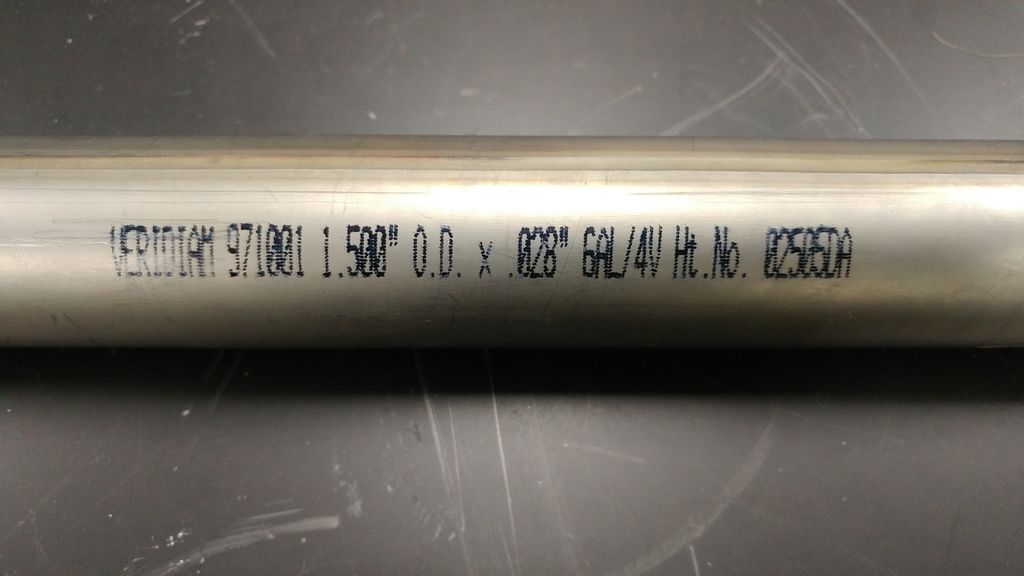

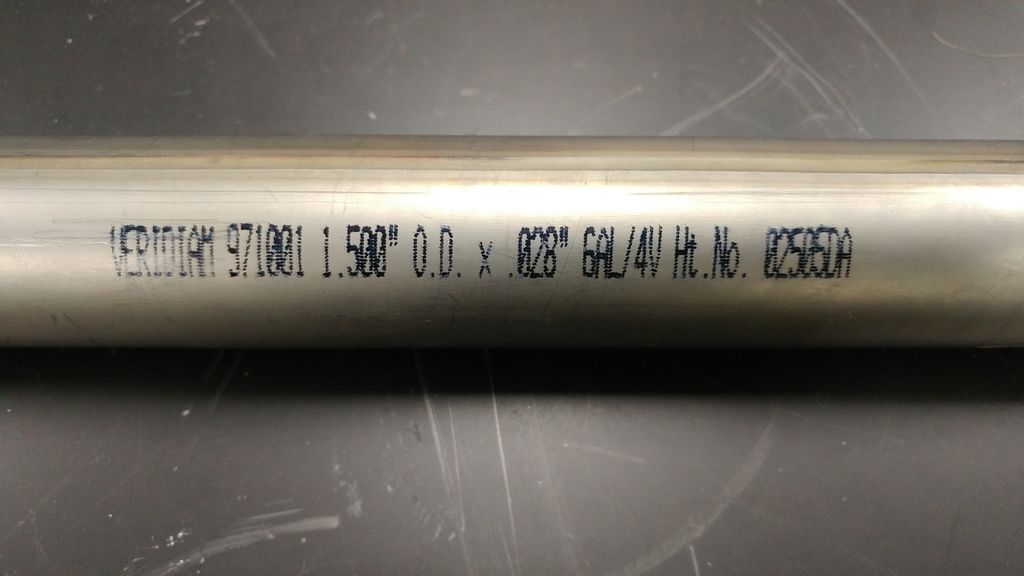

In the past I had problems with arc start and blow out. I contacted Arc Zone about the issue and they said people have had issues with the #24 cup not working right with anything less than 50 cfh. I was able to get mine working better when I increased the pre flow from one to two seconds. This is what the set up looks like with the 3/8 stick out. keep in mind that this cup is over 1.5 inches wide. Also Arc Zone recommends a minimum 3/4 inch stick out so you dont start toasting the screens in the cup. Ill set my stick out to 3/4 of an inch and go from there. Thanks for the replies. Its helping!

- Attachments

-

- tig3.jpg (35.16 KiB) Viewed 1112 times

-

- tig2.jpg (49.02 KiB) Viewed 1112 times

Yea that's 3/8" stick out, but you're not going to touch the tungsten to the puddle the way you have it in that pic, at least I hope not!  You're right though, 3/4" would work better though. But wouldn't it be a cool story if you injured your neck from tilting your head over, because you can say you were doing a high-dollar titanium job for the government??

You're right though, 3/4" would work better though. But wouldn't it be a cool story if you injured your neck from tilting your head over, because you can say you were doing a high-dollar titanium job for the government??

Don't those screens have a center guide to absorb the heat from the tungsten electrode? If they don't, then I can make better screens than Arc Zone. Tell ya what, just send the darn thing to me, and I'll show you how to use it. I have 100+ ft of Grade 5 titanium to weld up. Show ya how it's done, Son!

Tell ya what, just send the darn thing to me, and I'll show you how to use it. I have 100+ ft of Grade 5 titanium to weld up. Show ya how it's done, Son!

Don't those screens have a center guide to absorb the heat from the tungsten electrode? If they don't, then I can make better screens than Arc Zone.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Dang...your gonna have some fun...be sure to post up a few pics for us.Oscar wrote:Titanium tubular sub-frame for a Solar Car at my school. Body panels will be 4-8 layers Carbon Fiber. We ordered 2,250 ft².exnailpounder wrote:What's all that for Oscar?

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

Oh I will. If the students are able to get the AutoCAD drawings at least 80% finalized, we should be able to start this Saturday with both PVC pipe mock-up and the beginnings of the titanium sub-frame. The killer is going to be the notching of the Ti tubes. Gonna try a few different things to see what works best.exnailpounder wrote:Dang...your gonna have some fun...be sure to post up a few pics for us.Oscar wrote:Titanium tubular sub-frame for a Solar Car at my school. Body panels will be 4-8 layers Carbon Fiber. We ordered 2,250 ft².exnailpounder wrote:What's all that for Oscar?

Farmwelding

- Farmwelding

-

Weldmonger

-

Posts:

-

Joined:Thu Mar 10, 2016 11:37 pm

-

Location:Wisconsin

Oh I will. If the students are able to get the AutoCAD drawings at least 80% finalized, we should be able to start this Saturday with both PVC pipe mock-up and the beginnings of the titanium sub-frame. The killer is going to be the notching of the Ti tubes. Gonna try a few different things to see what works best.[/quote]

No expert on this matter nor do I know the end design but why titanium. Why not not aluminum or cheimoly to make it lighter. Like I said not an expert.

No expert on this matter nor do I know the end design but why titanium. Why not not aluminum or cheimoly to make it lighter. Like I said not an expert.

A student now but really want to weld everyday. Want to learn everything about everything. Want to become a knower of all and master of none.

Instagram: @farmwelding

Nick

Instagram: @farmwelding

Nick

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

No expert on this matter nor do I know the end design but why titanium. Why not not aluminum or cheimoly to make it lighter. Like I said not an expert.[/quote]Farmwelding wrote:Oh I will. If the students are able to get the AutoCAD drawings at least 80% finalized, we should be able to start this Saturday with both PVC pipe mock-up and the beginnings of the titanium sub-frame. The killer is going to be the notching of the Ti tubes. Gonna try a few different things to see what works best.

Chromoly is heavy, aluminum is nowhere near as strong as Ti. Ti is stronger than steel at fraction of the weight. Titanium is badass! I might order a welder sampler just to see how it welds.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Oscar have you tried that .030" yet? That thin rod is going to be like trying to hold a wet noddle, Ti is soft and that small dia is going to be a challenge, its not stiff like SST. Ok maybe a wet noddle is extreme, but it will be soft.Oscar wrote:0.030" Grade 23.motox wrote:Oscar

what rod are you using?

craig

I'll admit it has been awhile since I welded this, and I believe I was using CP filler (AMS 4951), but still I'm interested in your feedback

Richard

Website

Website

Yea I've used it. We actually ordered a 10# spool of it. So what I was checking out is how long of a piece to snip so it doesn't end up being too flimsy. I sure won't be using 36" long pieces that's for sure. More like 5-8" long pieces.LtBadd wrote:Oscar have you tried that .030" yet? That thin rod is going to be like trying to hold a wet noddle, Ti is soft and that small dia is going to be a challenge, its not stiff like SST. Ok maybe a wet noddle is extreme, but it will be soft.Oscar wrote:0.030" Grade 23.motox wrote:Oscar

what rod are you using?

craig

I'll admit it has been awhile since I welded this, and I believe I was using CP filler (AMS 4951), but still I'm interested in your feedback

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

All figured out. Had to drop my purge flow very low, to the point where the ball was just hovering over the seat. Ended up at 32 amps, 55 cfh, 1 inch stick out. When i backed off on the flow to 45 cfh and 1 inch stick out the arc was doing some funny things. here is what I got done so far. I know its not perfect but its a start.

- Attachments

-

- tig5.jpg (45.37 KiB) Viewed 1019 times

-

- tig4.jpg (66.52 KiB) Viewed 1019 times

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

With the Canadian to USA dollar is right now I try and do everything I can to keep my cups in top shape. I dont want to risk arcing out the screen. Im already starting to realize that titanium is one of the hardest materials to learn to weld.Oscar wrote:Looks good! So I guess you're not gonna send that cup my way, eh?

Farmwelding

- Farmwelding

-

Weldmonger

-

Posts:

-

Joined:Thu Mar 10, 2016 11:37 pm

-

Location:Wisconsin

Hey at least you're trying and getting some welds down. And every bit of welding had its own issues and learning curve.

A student now but really want to weld everyday. Want to learn everything about everything. Want to become a knower of all and master of none.

Instagram: @farmwelding

Nick

Instagram: @farmwelding

Nick

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities