Great job Kym!MosquitoMoto wrote:

Ever look at something and see something else?

This is what happened when I stared into a junk shop clutterbox of cutlery. It became a praying mantis.

Kym

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Wow is that cool! It looks amazingly like a mantis. Nice work! I may have to steal that one

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

- 20161125_072432.jpg (31.21 KiB) Viewed 2054 times

Sorry you have to break your neck to see it.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

My friend brought me a bucket full of railroad spikes so I started making these. Sold every one I have made so far. $20 per.

Sorry you have to break your neck to see it.

clever idea!

Sorry you have to break your neck to see it.

clever idea!

htp invertig 221

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Great stuff Exnail...looks really cool, the copper highlighting is clever. Well done.

Love seeing stuff repurposed in a crafty way.

Kym

Love seeing stuff repurposed in a crafty way.

Kym

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

Getting my titanium dialled in. Still lots of "dialling" to do. I know I need more practice with the start stops. Suggestions?

- Attachments

-

- IMG_1337.JPG (33.98 KiB) Viewed 1976 times

-

- IMG_1338.JPG (30.3 KiB) Viewed 1976 times

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Looks like you got a good ID purge, welding a short piece like that is a constant start and stop to reposition so it's a challenge (as you know).Skylineauto wrote:Getting my titanium dialled in. Still lots of "dialling" to do. I know I need more practice with the start stops. Suggestions?

Richard

Website

Website

- Skylineauto

-

Workhorse

-

Posts:

-

Joined:Mon Aug 10, 2015 9:45 am

Was able to get the tie ins a bit better. A bit straighter too

- Attachments

-

- IMG_1346.JPG (36.85 KiB) Viewed 1914 times

-

- IMG_1345.JPG (40.13 KiB) Viewed 1914 times

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

- 20161203_164000.jpg (53.92 KiB) Viewed 2200 times

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

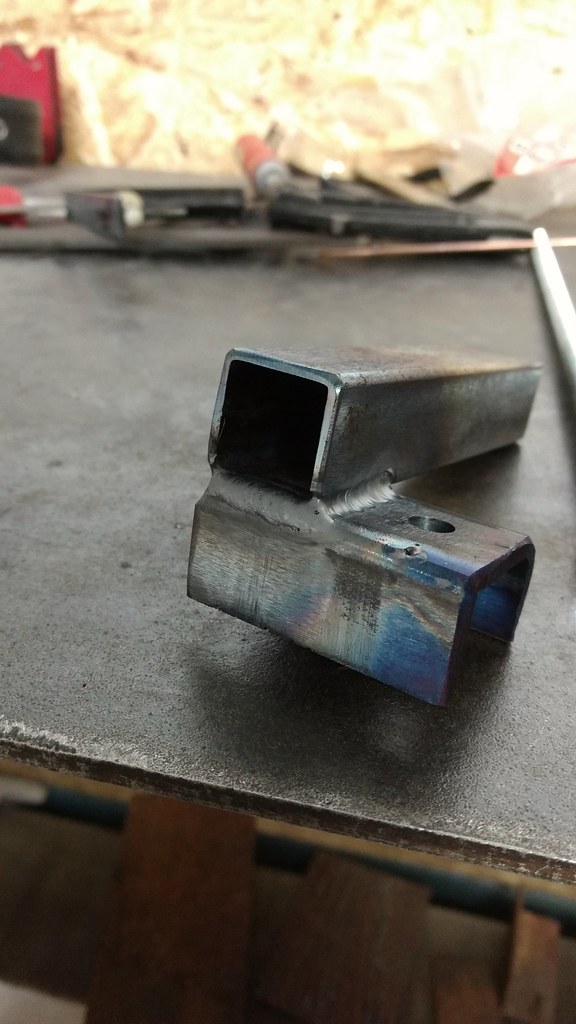

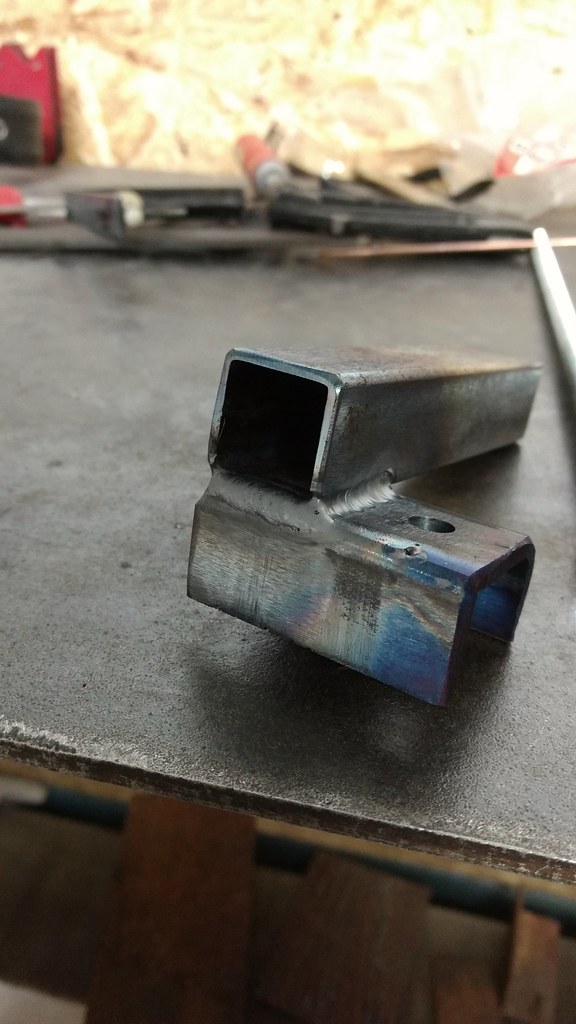

Building lower blade guides for my old* 24" wood cutting bandsaw, it only had some very simplistic side guides from factory, I am making new ones from scrap and it'll work like a set of carter guides:

* 50-70 years old, don't really know

* 50-70 years old, don't really know

CanMoulder

- CanMoulder

-

Active Member

-

Posts:

-

Joined:Wed Apr 22, 2015 1:02 pm

-

Location:Ontario Canada

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Nice to see some old machines getting some love.

Well done on the cast/silbr exnail. Sure beats trying to find a part.

And Dennis, I have an ancient band saw, I've often wondered what I'd do if I needed parts. I think you've answered my question...make them myself! Good work.

Kym

Well done on the cast/silbr exnail. Sure beats trying to find a part.

And Dennis, I have an ancient band saw, I've often wondered what I'd do if I needed parts. I think you've answered my question...make them myself! Good work.

Kym

Practicing on aluminum. This is also weak (left) handed welding. The aluminum is 1-1/2" wide x 1/8" thick. 200 amps with pedal control. AC frequency set to 200 Hz. AC Balance at 35%. 3/32" 2% Lanthanated Tungsten and 3/32" 4043 filler.

close up shot.

far away shot.

Dave

close up shot.

- IMG_4339.JPG (36.47 KiB) Viewed 2072 times

- IMG_4338.JPG (66.09 KiB) Viewed 2072 times

AHP AlphaTIG 200X

https://sites.google.com/site/davestelescope/home

https://sites.google.com/site/davestelescope/home

Dave, that's the only way to get better with the opposite hand, practice and more practice. I intentionally use my left hand a fair bit, now I switch when ever I need to and don't even think about it. It's never as perfect as my RH but it looks pretty damn good. Nice job.

Exnail- looks like a good score!

Exnail- looks like a good score!

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

had some extra aluminum lying around, needed practice on aluminum outside corners and wanted a couple heavy duty chainsaw boxes for 2 chainsaws I carry on my ATV so .... These are 1/8" 5052 aluminum, I scored the joints with my circular saw, bent them manually over a table edge, and then welded them with my Everlast 255EXT. Specs for welding were ~110a on outside corners (~125a to 130a at beginning then lowered as metal got warm), no pulse, 3/32" tungsten and 5356 filler, 3 sec upslope and 3 sec down using an on/off torch switch and slope to control heat. Handles were made with some tubing and a couple pieces of plate. Aluminum hinges were purchased and welded on. Fun project, lots of TIG seat time, 255EXT performed great.

- Attachments

-

- Two boxes

- IMG_5163[1].JPG (40.08 KiB) Viewed 1973 times

-

- Hinge side

- IMG_5158[1].JPG (39.07 KiB) Viewed 1973 times

-

- latch side

- IMG_5159[1].JPG (49.3 KiB) Viewed 1973 times

-

- Inside box w/chainsaw

- IMG_5165[1].JPG (45.3 KiB) Viewed 1973 times

Jim S.

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

LOVE the chainsaw boxes, well done.

They also make me giggle. It's a bit like wrapping a giraffe in brown paper, isn't it? "So....what's in the box?"

Kym

They also make me giggle. It's a bit like wrapping a giraffe in brown paper, isn't it? "So....what's in the box?"

Kym

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Holy Cow! You must really love your chainsaws!  Actually I get it, I have a couple nice saws that I take really good care of and make sure they are always cased when not in use. Great job...very unusual job ..but great nonetheless.

Actually I get it, I have a couple nice saws that I take really good care of and make sure they are always cased when not in use. Great job...very unusual job ..but great nonetheless.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

- C. Livingstone

-

Guide

-

Posts:

-

Joined:Sat Dec 03, 2016 9:22 am

Whoa,

Those chainsaw boxes are freaky cool!

Those chainsaw boxes are freaky cool!

Peace be with you all,

Christian Livingstone

www.youtube.com/newjerusalemtimes

Everlast AC/DC 210EXT (2015)

CAT250D DC-TIG/Plasma Combo

Christian Livingstone

www.youtube.com/newjerusalemtimes

Everlast AC/DC 210EXT (2015)

CAT250D DC-TIG/Plasma Combo

Thanks for the comments on the chainsaw boxes, enjoyed them. Kym, the Giraffe comment had me rolling.  I needed some serious practice on outside corners to build some gas tanks later this year and this seemed more fun than making modern art for the recycle. As well, don't want the chainsaw I take hunting getting beat up on the trip. Bar oil reservoir is filled with vegetable oil and the saw has double duty cutting up campfire wood and cleaning moose. Would not want a broken chainsaw and have to go back to using a hand saw for either task, getting too old for that.

I needed some serious practice on outside corners to build some gas tanks later this year and this seemed more fun than making modern art for the recycle. As well, don't want the chainsaw I take hunting getting beat up on the trip. Bar oil reservoir is filled with vegetable oil and the saw has double duty cutting up campfire wood and cleaning moose. Would not want a broken chainsaw and have to go back to using a hand saw for either task, getting too old for that.

Last edited by shipj0 on Tue Jan 03, 2017 8:58 pm, edited 2 times in total.

Jim S.

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

That is nice work. I have seen videos of welding cast and it seems very challenging. I think I would have contracted that one out at my skill level.exnailpounder wrote:20161203_164000.jpgRather proud of this. Bought a new to me lathe and the feed direction lever got broke so I Sil-brazed it back together and had to re-drill the hole for the return spring. Paper thin cast iron and mildly expensive to replace so I was puckered but I pulled it off. Silbr is harder to drill than cast.

Jim S.

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

Miller 211 Autoset

Everlast 255EXT

Everlast Water Cooler (2)

Everlast PowerPlasma 80S

Longevity 250MP

Lincoln 350MP Aluminum

Hypertherm 30Air

Everlast 350EXT

Started practice on welding SS today. Cut about 30 strips to weld back together.

Between 0.55mm and 0.7mm

First ones looked pretty crap. But fiddled with the settings and got something good enough for the moment.

I'm planning on fabricating a 0.55mm inconel exhaust for my bike early next year. Far cheaper to practice on SS though.

As it turns out inconel welds better than SS ... well for me anyway.

https://goo.gl/photos/PNZvFcDA9E6Ftkao9

Between 0.55mm and 0.7mm

First ones looked pretty crap. But fiddled with the settings and got something good enough for the moment.

I'm planning on fabricating a 0.55mm inconel exhaust for my bike early next year. Far cheaper to practice on SS though.

As it turns out inconel welds better than SS ... well for me anyway.

https://goo.gl/photos/PNZvFcDA9E6Ftkao9

- inco.jpg (39.81 KiB) Viewed 2006 times

Nowadays people know the price of everything and the value of nothing... Oscar Wilde

Finished up the blade guides and welded on a piece of angle iron with a slot in it that retains the thrust bearing. No problem in mounting this 1" 1.3 TPI ripping blade. This has way more adjustment range than I will ever need...

Perhaps I'll give it a coat of paint to look more professional, but it won't be visible inside the enclosre.

Perhaps I'll give it a coat of paint to look more professional, but it won't be visible inside the enclosre.

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities