I've done a bit of looking around but can't find any answers.

Have just purchased a new dual argon regulator for my Tig. I buy everything online because my LWS is variously hopeless/has no stock/is prohibitively expensive/ has no idea. Three issues:

* The stem on my new reg is a small male fitting with a collar.

* My bottle is large female, no need for collar.

* As supplied, the new dual regulator would fit up to the bottle with both flow meters and gauge sitting horizontal.

So...I have the correct stem with the large male fitting. Can I remove what's on the new regulator and fit the correct stem without any risk? Also, can I swing the flow meters around 90 degrees so that they sit upright, also with no risk? I don't care about the gauge, that can continue to sit flat.

Any tips? All seems straightforward, but don't want to blow myself to bits.

Cheers,

Kym

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Assuming the threads are the same spec then yes you should be able to do so quite readily. Quite often gas threads are tapered which enables them to seal when tightened without the need for teflon tape, but you can use a bit to seal if you want to. A few wraps around the male threads is all that is needed. Don't overtighten.. Just nip them up.MosquitoMoto wrote:

So...I have the correct stem with the large male fitting. Can I remove what's on the new regulator and fit the correct stem without any risk?

Yes you can. Back the coupling nut off a turn or so and reposition the meters as required and then retighten the nut. Don't overtighten though. And make sure that you use 2 spanners when loosening and tightening the fittings. Once assembled, install onto your cylinder and open the valve slowly. Spray some soapy water solution onto the fittings that you played with to check for leaks. The formation of bubbles will be the sign that a leak is present.

Also, can I swing the flow meters around 90 degrees so that they sit upright, also with no risk? I don't care about the gauge, that can continue to sit flat.

Any tips? All seems straightforward, but don't want to blow myself to bits.

Flo

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

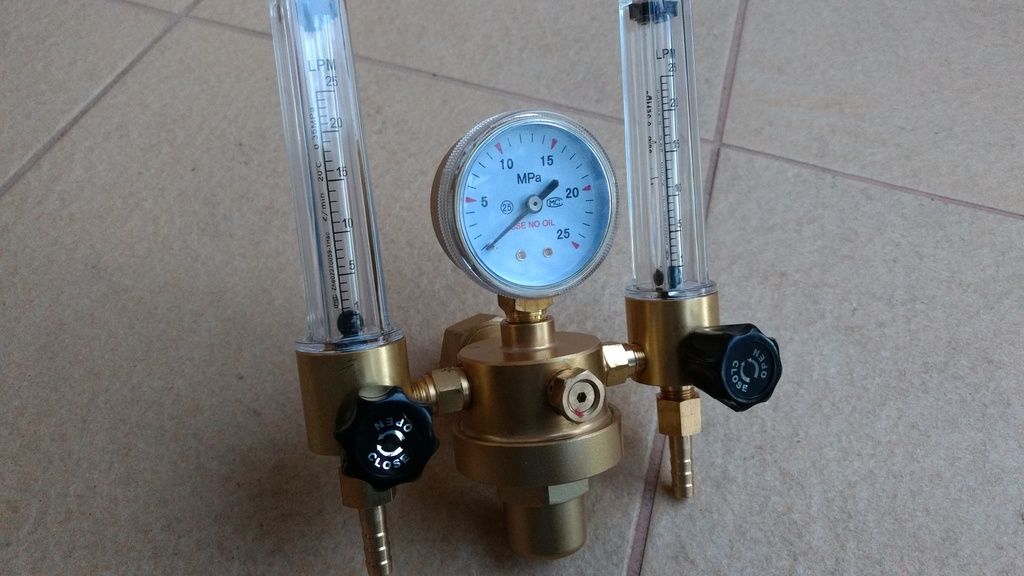

Here it is. I won't bore you with the convoluted story of how I wound up with this one, but I'm working with what I have. Thanks for your advice thus far.

Kym

Hey Kym,

I'd give it a go but I reckon you will need to use some teflon tape or a liquid thread sealant. From the looks of the nipple it appears to be a tapered thread where it attaches to the flow meter and possibly a parallel thread fitted to the regulator body.

You might need to remove the nipple from the reg to see how many threads you have to play with.

I'd give it a go but I reckon you will need to use some teflon tape or a liquid thread sealant. From the looks of the nipple it appears to be a tapered thread where it attaches to the flow meter and possibly a parallel thread fitted to the regulator body.

You might need to remove the nipple from the reg to see how many threads you have to play with.

I'm with Oz. You can do it. I've changed fittings before. I would use a thread sealant that's liquid based. I stay away from teflon tape on anything that's gas or oil like. Tends to get teflon strings and bits inside the regulator. Don't buy just any pipe dope. There not all equal. Your looking for one that's labeled thread lubricant and sealant.

I have more questions than answers

Josh

Josh

Tom Osselton

- Tom Osselton

-

Workhorse

-

Posts:

-

Joined:Sat Aug 15, 2015 12:33 am

-

Location:Calgary Alberta

I have the same one and had to change the bottle fitting with no problems, I did find though that I went through gas alot faster so if you can check your flow with a torch/flow meter.

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Thanks for the input, folks - I'm going to give this a shot.

(Opens valve slowly, eye protection, fingers in ears...)

Kym

(Opens valve slowly, eye protection, fingers in ears...)

Kym

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

A little update.

With much aggro I have managed to turn the flowmeter tubes and also remove the gas bottle fitting. I had to break one of my own personal rules to do it though. I own dozens and dozens of spanners, both metric and imperial, and not one of them quite fitted the nice, soft brass fittings. Damn. So I used...a shifting spanner. An act of pure butchery by my standards. Needless to say the fittings suffered as a result.

However....now all I need to do is source a male main fitting so that I can attach the reg to my argon bottle, test for leaks and I'm good to go.

Kym

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities