Aaron

hats off.

would love to see some pics of your shop.

(if they are not classified,lol)

craig

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

Top secret, sorry.motox wrote:Aaron

hats off.

would love to see some pics of your shop.

(if they are not classified,lol)

craig

Just kidding, I haven't taken any good photos of the shop. If I do, I'll post them.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

I have to agree wholeheartedly with this.Aaron@6061.com wrote: ...I can make them look just as good with my old Syncrowave 180 other than the white etched area on the sides of the weld is much wider. I think a lot of people get discouraged and think they would be a much better welder if only they had more expensive equipment, but I don't that is true for the most part...

If you have solid equipment (there is some junk out there), your results are the product of your hands and eyes, not the technology.

Aaron, you do beautiful work. Aluminum is a favorite of mine, and I don't get to weld it often enough.

Steve S

Sir Aaron ( I give the title of knight in welding ) , I'm impress too , I have never seen work like this , do you accept me a student of yours as in the films where

the student is willing to do anything just to get close to the master and his teachings.I'm in Greece but I'm willing to swim the

Atlantic to US.I'm trying many years and I cannot do a decent welding , for this reason I bought a very expensive machine

to help me to achieve better results.

the student is willing to do anything just to get close to the master and his teachings.I'm in Greece but I'm willing to swim the

Atlantic to US.I'm trying many years and I cannot do a decent welding , for this reason I bought a very expensive machine

to help me to achieve better results.

Yeah it's a F105mm typeo before, had it a few years but I'm thinking of going to the clamshell setup by welding on the ferrule they offer. I'll keep you in mind, I still build motors but not nearly as many as I use to after switching day jobs. I used another one of my contacts in the industry that's an Accufab dealer, they do make an impressive piece.Aaron@6061.com wrote:Thanks. Yeah, I use a Dynasty 350. I can make them look just as good with my old Syncrowave 180 other than the white etched area on the sides of the weld is much wider. I think a lot of people get discouraged and think they would be a much better welder if only they had more expensive equipment, but I don't that is true for the most part.Rick_H wrote:Nice work indeed....hope to finally make one of those later this summer after I finish my sheet metal intake for my 4.6 with a 100mm Accufab. I've done a lot of testing with TBs over the years Accufab is right at the top, the Wilson Manifolds pieces did well also.

Beautiful work I'm assuming those are done with an newer Dynasty setup

Accufab makes the highest quality throttle bodies in my opinion... I have seen all brands and that's why I am a dealer for only Accufab. Oh, and I think you must mean some other size than 100mm. To the best of my knowledge, they don't offer a 100mm. I sell a ton of 90mm and 105mm ones in the old 5.0 Mustang bolt pattern. Hit me up when you are ready to purchase one if you haven't already.

I agree on the machine but technology sure has helped if you know what your doing with those settings. I remember the first time I used a 350LX Dynasty for a weld test..when it was done they allowed me to mess around, I was very impressed. One may find its way in my shop shortly. If you dont mind me asking whos cores do you like on the A/W units? Beautiful work!

This threads makes.me want to crank out some Alum practice, I weld stainless nearly 98% of the time now days.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

Care to elaborate on the gas your using...straight argon or a custom blend?Aaron@6061.com wrote:Weld settings:

60-350 hertz. Doesn't really matter... I get tired of the same sound so I change it around. Just make sure your puddle isn't shaking around a lot. One time I had it at 145 hz and it did not like that for some reason... The puddle was shaking all over the place. I changed it a few HZ and it stabilized.

200A EN

150A EP

80% balance

15CFH gas flow (for indoor welding with zero air movement)

Sir Aaron and rest of forum , definitely there is something more than the usual , me too I want to know please all details possible to the Technic used , like the rod diameter if it is gas lens , what size tungsten ,type , alumina diameter everything .

If is acetone cleaned before welding . Many can try but few can win a metal in olympic games of welding still I'm Impressed

well done Sir Aaron ...

If is acetone cleaned before welding . Many can try but few can win a metal in olympic games of welding still I'm Impressed

well done Sir Aaron ...

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

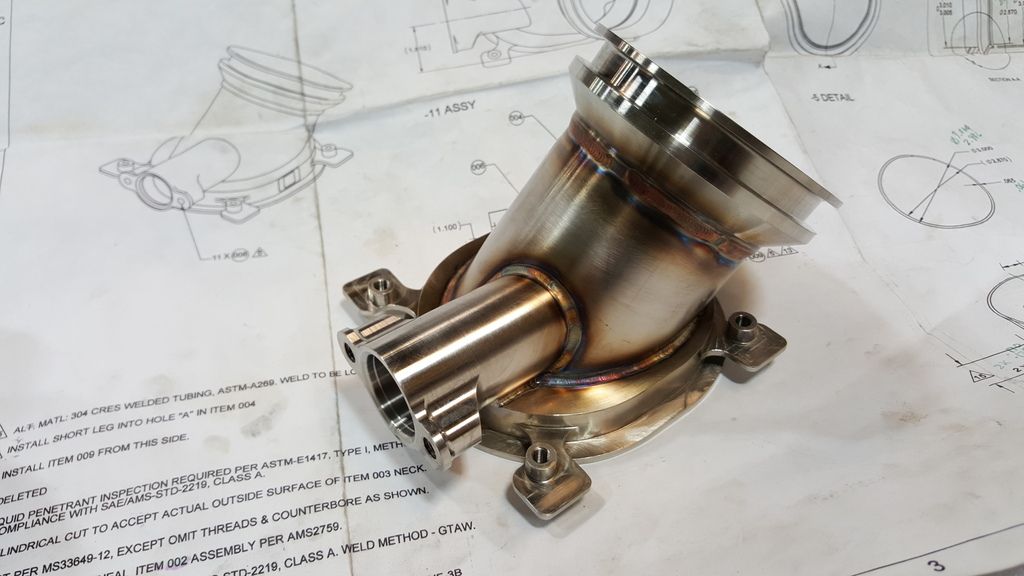

I never got too serious about selling A/W intercoolers, so I just told my customers to send me whatever cores they liked. If I remember correctly, Bell intercooler cores were the best to work with (but sometimes pretty pricey depending on dimensions). I haven't built any intercoolers for probably 6 years. This was one of the last ones I did:Rick_H wrote: If you dont mind me asking whos cores do you like on the A/W units? Beautiful work!

Last edited by Aaron@6061.com on Sun Jan 31, 2016 3:26 pm, edited 1 time in total.

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

dunkster wrote: Care to elaborate on the gas your using...straight argon or a custom blend?

Straight argon unless I'm welding 1/2" or thicker aluminum. Then I use a 75Argon/25Helium mix.

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

I just bought 3 cameras and I'm going to start making an aluminum fabrication welding how-to video for beginner and intermediate welders. I'll attempt to get the cameras set up to grasp my point of view, a side view (to show filler rod feeding technique), a foot pedal view and/or welder output view, all at the same time. I'll show and explain absolutely everything, from start to finish. Not only the welding side of things, but also the fabrication and fitment from start to finish. I'll show every single tool I use, and explain why.ESENTI wrote:Sir Aaron and rest of forum , definitely there is something more than the usual , me too I want to know please all details possible to the Technic used , like the rod diameter if it is gas lens , what size tungsten ,type , alumina diameter everything .

If is acetone cleaned before welding . Many can try but few can win a metal in olympic games of welding still I'm Impressed

well done Sir Aaron ...

There are several misconceptions about aluminum welding that seem to almost be set in stone as the "standard", or the "right way to do it" that I personally don't agree with, and I'll explain those too.

I'll be using a simple Miller Syncrowave 180 and also Miller Dynasty 350.

Troy Boy 72

- Troy Boy 72

-

Active Member

-

Posts:

-

Joined:Thu Dec 31, 2015 7:22 pm

-

Location:Mackay North QLD

Aaron or one of my new friends out there please explain to me what 200A EN , 150A EP , 80% balance means as I'm learning on a 210 EXT 2015 model this is not really making sense . I'm guessing its some settings on that miller 350. Thanks

Troy

Troy

Aaron@6061.com

- Aaron@6061.com

-

Active Member

-

Posts:

-

Joined:Thu Jan 14, 2016 10:16 am

On the higher end TIG welders, the EN (electrode negative) and EP (electrode positive) amperages can be adjusted independently. Those settings may not be available on your welder.Troy Boy 72 wrote:Aaron or one of my new friends out there please explain to me what 200A EN , 150A EP , 80% balance means as I'm learning on a 210 EXT 2015 model this is not really making sense . I'm guessing its some settings on that miller 350. Thanks

Troy

Here is an article that goes into more detail about wave balance:

https://www.millerwelds.com/resources/a ... ce-control

Jody has a Youtube video on this subject:

https://www.youtube.com/watch?v=RG4ZOwSw9CQ

Will be following with interest.Aaron@6061.com wrote:I just bought 3 cameras and I'm going to start making an aluminum fabrication welding how-to video for beginner and intermediate welders. I'll attempt to get the cameras set up to grasp my point of view, a side view (to show filler rod feeding technique), a foot pedal view and/or welder output view, all at the same time. I'll show and explain absolutely everything, from start to finish. Not only the welding side of things, but also the fabrication and fitment from start to finish. I'll show every single tool I use, and explain why.ESENTI wrote:Sir Aaron and rest of forum , definitely there is something more than the usual , me too I want to know please all details possible to the Technic used , like the rod diameter if it is gas lens , what size tungsten ,type , alumina diameter everything .

If is acetone cleaned before welding . Many can try but few can win a metal in olympic games of welding still I'm Impressed

well done Sir Aaron ...

There are several misconceptions about aluminum welding that seem to almost be set in stone as the "standard", or the "right way to do it" that I personally don't agree with, and I'll explain those too.

I'll be using a simple Miller Syncrowave 180 and also Miller Dynasty 350.

Everlast 250EX

Miller 250 syncrowave

Sharp LMV Vertical Mill

Takisawa TSL-800-D Lathe

Coupla Bandsaws,Grinders,surface grinder,tool/cutter grinder

and more stuff than I deserve(Thanks Significant Other)

Miller 250 syncrowave

Sharp LMV Vertical Mill

Takisawa TSL-800-D Lathe

Coupla Bandsaws,Grinders,surface grinder,tool/cutter grinder

and more stuff than I deserve(Thanks Significant Other)

Troy Boy 72

- Troy Boy 72

-

Active Member

-

Posts:

-

Joined:Thu Dec 31, 2015 7:22 pm

-

Location:Mackay North QLD

Hey thanks Aaron , as a learner (self taught ) I'm finding somethings little more confusing than others but with the more practise and seat time i get combined with reading and help from the awesome guys here the more I'm understanding and welding better .Im also noticing more and more things every time i light up. Thanks also for taking the time to start making some videos ,I'm sure they will be very knowledgeable . thanks

Troy

Troy

Hollywood1

- Hollywood1

-

Ace

-

Posts:

-

Joined:Mon Feb 23, 2015 9:05 am

-

Location:Washington

Welded this aluminum boat rack for fishing pole and net storage. Had some trouble with the tubing bringing lots of crud up into the weld. never had this problem. Any ideas? Thanks John.

- Attachments

-

- 20160202_132648.jpg (45.01 KiB) Viewed 1942 times

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

@tamjeffHollywood1 wrote:Welded this aluminum boat rack for fishing pole and net storage. Had some trouble with the tubing bringing lots of crud up into the weld. never had this problem. Any ideas? Thanks John.

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

@tamjeffHollywood1 wrote:Welded this aluminum boat rack for fishing pole and net storage. Had some trouble with the tubing bringing lots of crud up into the weld. never had this problem. Any ideas? Thanks John.

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

Finally, a project for me!

My version of an Alaskan chain saw mill. Decided to incorporate some delrin guides for stability, given the diameter logs being cut. Very pleased how it performed, though a ripping chain I'm sure would've sped things up a bit. Sorry for the pic quality.

My version of an Alaskan chain saw mill. Decided to incorporate some delrin guides for stability, given the diameter logs being cut. Very pleased how it performed, though a ripping chain I'm sure would've sped things up a bit. Sorry for the pic quality.

- Attachments

-

- DSCN0804.JPG (49.38 KiB) Viewed 1731 times

It's probably me that don't know about it. Its just that its looks to me like one vice-grip slip away from loosing a leg or two. Not trying to be funny or anything its just how it looks to me.

Flat out like a lizard drinkin'

Lol, got it. I guess one could see it that way.

No the bar was clamped using two 1/2" bolts at each clamp, so that wasn't going anywhere. The weld clamp you see was put on to use as a handle so the guides had even load, otherwise it would bind up. And cut was being made on the back cut side of bar, not the usual side...so yes, I was pulling on the clamp, not pushing on it. Chose that direction so that in case of a chain break, the uncut portion of log would retain it somewhat vs. swinging thru the gap from the cut and taking parts of me with it. Hope that made sense.

No the bar was clamped using two 1/2" bolts at each clamp, so that wasn't going anywhere. The weld clamp you see was put on to use as a handle so the guides had even load, otherwise it would bind up. And cut was being made on the back cut side of bar, not the usual side...so yes, I was pulling on the clamp, not pushing on it. Chose that direction so that in case of a chain break, the uncut portion of log would retain it somewhat vs. swinging thru the gap from the cut and taking parts of me with it. Hope that made sense.

Advancedynamix

- Advancedynamix

-

New Member

-

Posts:

-

Joined:Thu Aug 06, 2015 4:56 pm

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities