Hi,

I was out in the garage earlier and had a hour spare so thought i would quickly tack some stainless exhaust together, the rate I'm building this thing is like a bend a fortnight so its taking forever but anyways....

one part of the job was to tack the 1.6mm 304 SS pipe to a stainless Vband flange (roughly 3-4mm thick,unsure of grade, possibly 316), I found that it was next to impossible to get the arc to puddle both the pipe and the Vband flange because the arch would just want to go towards the thicker material on the flange..... what am i doing wrong? what causes the arc to wander?

I have had this problem welding alloy too, mostly when welding AN fitting nipples onto alloy sheet or pipe.

My spidey senses tell me the common denominator is the fact that there is a thicker material and a thinner one in each scenario but how do i fix it?

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

88MOOSE88

- 88MOOSE88

-

Active Member

-

Posts:

-

Joined:Fri Jul 11, 2014 11:13 am

-

Location:Grimsby, united kingdom

Hi,

Wondering arc on stainless steel is a pain especially on thin material.

Try a really fine point on the tungsten with no contaminates on it. Even try a 1/16 tungsten.

Use just enough amps as it takes to just form a good size puddle on the thicker material and add filler (1.6mm) then wash the pool over to the thin stainless steel part, keep a really really tight arc. Move slow enough to keep the bead uniform.

Keep the angle pointing at the thicker part at about 30 - 35 degrees.

Purge the pipe section to, you'll find that you will most likely melt through on the thinner material, just as a precaution.

Use pulse if your machine has it.

A gas lens will help also.

If your unsure on grade of material use 309.

Hope this helps

Wondering arc on stainless steel is a pain especially on thin material.

Try a really fine point on the tungsten with no contaminates on it. Even try a 1/16 tungsten.

Use just enough amps as it takes to just form a good size puddle on the thicker material and add filler (1.6mm) then wash the pool over to the thin stainless steel part, keep a really really tight arc. Move slow enough to keep the bead uniform.

Keep the angle pointing at the thicker part at about 30 - 35 degrees.

Purge the pipe section to, you'll find that you will most likely melt through on the thinner material, just as a precaution.

Use pulse if your machine has it.

A gas lens will help also.

If your unsure on grade of material use 309.

Hope this helps

CaveMechanic

- CaveMechanic

-

New Member

-

Posts:

-

Joined:Thu May 01, 2014 10:12 am

Back to basics?

electricity follows the path of least resistance.

so if the thinner material fits inside the thicker stuff, try direct grounding the thinner material, this will force the arc to be drawn to the thinner material thru the thicker material.

and remember to really sharpen your tungsten

hope this helps

electricity follows the path of least resistance.

so if the thinner material fits inside the thicker stuff, try direct grounding the thinner material, this will force the arc to be drawn to the thinner material thru the thicker material.

and remember to really sharpen your tungsten

hope this helps

Also difference between sulfur levels of two metals can cause wandering. It is very well known problem in autogenous orbital welding. Sometimes it can lead to total failier of the weld.

Here is video what mismacthed sulfur content will do in your stainless weld.

https://www.youtube.com/watch?v=LnEwHEAyI40

Here is video what mismacthed sulfur content will do in your stainless weld.

https://www.youtube.com/watch?v=LnEwHEAyI40

-Markus-

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

One other possibility, and this may surprise you, is magnetism in one or both pieces.

As unlikely as it sounds, it happens... I cut out (at a total repair cost in the tens of thousands of dollars) some stainless parts clearly marked 304/304L, that were as easily lifted by my pick-up magnet as any carbon steel. Each section I cut out was marked "Made in China", and failed miserably in a cryogenic application where the 304 was the ideal choice, and joined by really impressive welds.

Check your parts with a magnet, and see how much attraction you get... You may have to degauss it to put the arc where you want it.

Steve S

As unlikely as it sounds, it happens... I cut out (at a total repair cost in the tens of thousands of dollars) some stainless parts clearly marked 304/304L, that were as easily lifted by my pick-up magnet as any carbon steel. Each section I cut out was marked "Made in China", and failed miserably in a cryogenic application where the 304 was the ideal choice, and joined by really impressive welds.

Check your parts with a magnet, and see how much attraction you get... You may have to degauss it to put the arc where you want it.

Steve S

What kind of a joint was it? Was a 90° inside corner? How much amperage? what kind of a taper on the tungsten? flow-rate? cup size? ETC ETC ETC

The point is, without you giving out enough information, you're asking us to guess like if it was a game show. Help us help you by disclosing everything up front, including pictures of the joint and torch angle. In 2014, EVERYONE has access to a mobile camera phone.

The point is, without you giving out enough information, you're asking us to guess like if it was a game show. Help us help you by disclosing everything up front, including pictures of the joint and torch angle. In 2014, EVERYONE has access to a mobile camera phone.

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

Well the only camera I have is 35mm film which is hard to upload ! neither do I own a phone with camera & am not likely to - some of us do not keep up with trends in technology - I'm sure I'm not the only one & not everyone is comfortable enough here to post pictures of a weld that they are clearly unhappy about themselves - I agree a picture helps in diagnosis - but the OP's question is valid on it's own without cross examination ( in my opinion ) - when I had access to an old dinosaur Tig at a place I'd worked for I never had any real issues except lack of regular practice - having welded with a variety of inverters both of my own & while trying to teach people how to weld with their own mostly Ebay purchases I've come across this arc wander issue to the point you will melt one piece through while trying to add filler & the pool refuses to bridge the two - even on machined fit pipes that should autogenous weld will come to a certain point then refuse to join - continued attempts usually resulting in a keyhole - tube for handrails is a another one where many pieces cut from the same length of tube react differently - they also seem to erode tungsten fast & are very sensitive to surface finish from grinding - I've never had an explanation that made sense - except they are always Chinese welders - as it's not possible to turn the HF off on the ones I've seen I have been unable to hook my oscilloscope up to see what the output looks like - but I question if it's the machine rather than any other factor - I've not had the opportunity to try a good machine out to see if there is much difference - but the imports I've used have an erratic arc especially at lower amps plus weird start issues on AC irrespective of what color or sticker is on the box - I'd appreciate any thoughts on this - ( yes I know - win the Lotto & call Miller !! )

Yes that may be true, but to have access to one doesn't mean you have to own one. Access is one thing, ownership is another.noddybrian wrote:Well the only camera I have is 35mm film which is hard to upload ! neither do I own a phone with camera & am not likely to

Thanks for the reply guys much appreciated, like I said in the op that I was rushed for time and literally had a hour to spare and couldn't take a photo as the part was tacked and bolted under the car.

I will take a pic shortly

Cheers

I will take a pic shortly

Cheers

Rubbin' is racin' son

This expands on what Markus posted:

http://www.thefabricator.com/article/tu ... al-welding

And also, as Steve pointed out, check the magnetism. Not all regions produce the same quality. We get fitting from multiple countries and they not only rarely fit well, but also have differnt magnetic properties on the same material; typically 304/304L.

You said the flange was a stainless of an unknown grade. Well, ferritic stainless is common with exhaust piping. It's also highly magnetic. Duplex is also very magnetic, but somehow I doubt that's what you have. Not saying it is ferritic, but could be. And different grades weld differently.

http://www.thefabricator.com/article/tu ... al-welding

And also, as Steve pointed out, check the magnetism. Not all regions produce the same quality. We get fitting from multiple countries and they not only rarely fit well, but also have differnt magnetic properties on the same material; typically 304/304L.

You said the flange was a stainless of an unknown grade. Well, ferritic stainless is common with exhaust piping. It's also highly magnetic. Duplex is also very magnetic, but somehow I doubt that's what you have. Not saying it is ferritic, but could be. And different grades weld differently.

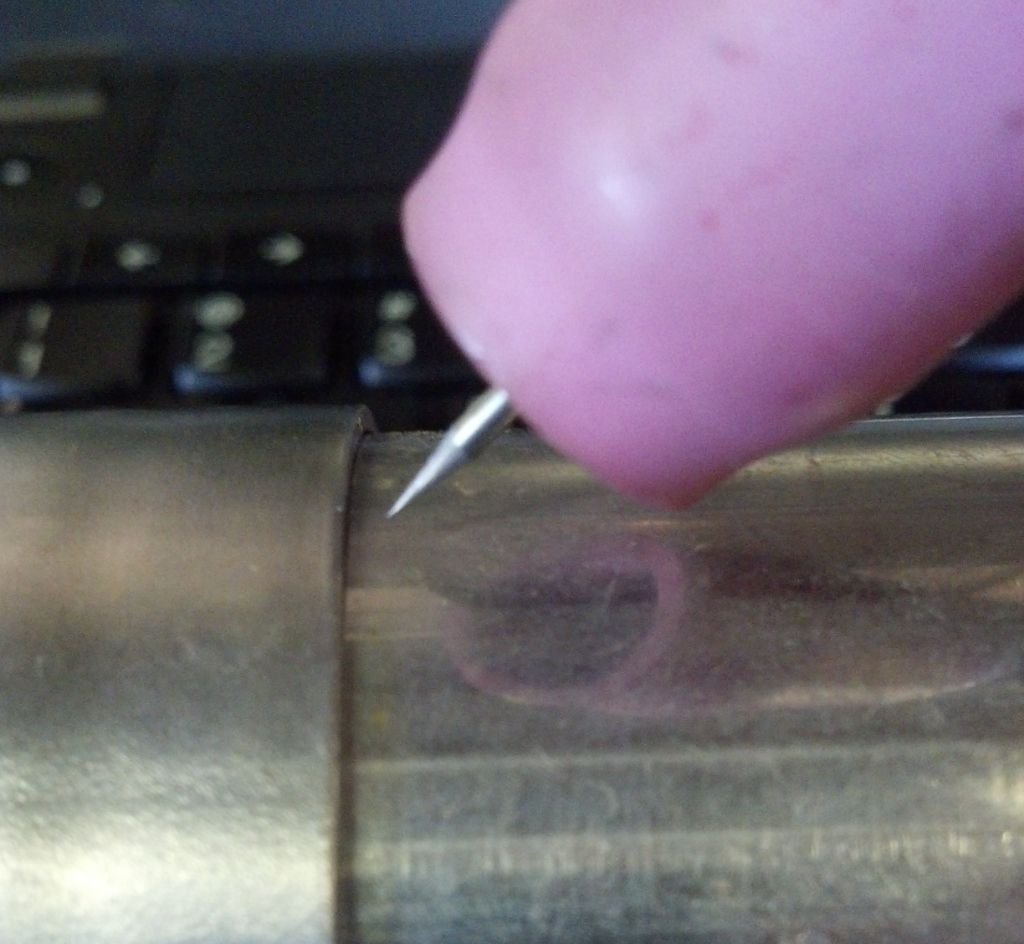

So this is the job piece, the 4" 304 pipe slips into the flange really snug. I guess you would call it a lap joint;

I'm using a 3/32 electrode with a #6 cup and gas lens @ 40amp with pure argon

I've had arc wander before but this was beyond a joke. I resorted to making a puddle on the pipe, dropping filler on it until I could get the filler up to a similar height as the flange at which point the arc would stabilise a bit and puddle but materials. At one point I was trying to puddle the pipe and the arch was still trying to jump to the flange, I was about 5mm away from where I was actually trying to form a puddle!!! If I had to guess, I would say my electrode was 3mm from the work piece.

I don't think it's a material issue as I welded the other half of the flange as seen in my pic and that worked out ok, and by ok I mean as good as my welding skills would allow

Thanks in advance

I'm using a 3/32 electrode with a #6 cup and gas lens @ 40amp with pure argon

I've had arc wander before but this was beyond a joke. I resorted to making a puddle on the pipe, dropping filler on it until I could get the filler up to a similar height as the flange at which point the arc would stabilise a bit and puddle but materials. At one point I was trying to puddle the pipe and the arch was still trying to jump to the flange, I was about 5mm away from where I was actually trying to form a puddle!!! If I had to guess, I would say my electrode was 3mm from the work piece.

I don't think it's a material issue as I welded the other half of the flange as seen in my pic and that worked out ok, and by ok I mean as good as my welding skills would allow

Thanks in advance

- Attachments

-

- Other side that was welded earlier

- image.jpg (40.96 KiB) Viewed 1670 times

-

- image.jpg (24.47 KiB) Viewed 1670 times

-

- image.jpg (45.17 KiB) Viewed 1670 times

Rubbin' is racin' son

Also I know the pics arnt the best that's because I had to get under the car to take them and the light isn't the best under there .... Might be because it's a bottomless pit were my money and time go, never to return again

Rubbin' is racin' son

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

@ oscar - did'nt mean to rant - sorry if it came over that way - had'nt thought of borrowing a camera phone - I guess many people have them now - never asked around - I don't borrow stuff or ask anyone for favors - just not my nature - I did once put a picture up -but only to get a " mate " off my case - he took it with a camera he had of a not that great 3rd hand tool on my bench - he'd never seen one so thought is was " rocket science " & kept on about the thing !

The magnetism is an interesting thought I'd not considered - next piece I do I'll check - it had never occurred to me as most stainless I weld is 316 - rarely know it's origin so I guess it could come from " Bongo " land.

Without any scientific method of testing welder output against a known machine is it possible that the low end machines on Ebay being Mosfet power conversion ( mostly ) exhibit strange characteristics due to the sheer number of them all requiring to work simultaneously - if you look inside them there are a significant number often on two or more heat sinks - as each operates switching a small % of the total current is there any difference in " gate" characteristic that would cause unusual effects in the output as whole ?- the better machines seem to be IGBT power conversion which appears to have very few modules handling the current - obviously transformer machines would not suffer with this as the power is from one source - only area of doubt being if a diode is going bad as happens sometimes with a Mig - any " tech " guys out there got a theory ?

The magnetism is an interesting thought I'd not considered - next piece I do I'll check - it had never occurred to me as most stainless I weld is 316 - rarely know it's origin so I guess it could come from " Bongo " land.

Without any scientific method of testing welder output against a known machine is it possible that the low end machines on Ebay being Mosfet power conversion ( mostly ) exhibit strange characteristics due to the sheer number of them all requiring to work simultaneously - if you look inside them there are a significant number often on two or more heat sinks - as each operates switching a small % of the total current is there any difference in " gate" characteristic that would cause unusual effects in the output as whole ?- the better machines seem to be IGBT power conversion which appears to have very few modules handling the current - obviously transformer machines would not suffer with this as the power is from one source - only area of doubt being if a diode is going bad as happens sometimes with a Mig - any " tech " guys out there got a theory ?

I believe that is part of the problem. 3mm is ≈ 1/8". For thin tubing like that, it's way too much arc length especially if you just put a "whatever" point on the tungsten. Take your tungsten (ideally a 1/16") and sharpen it about 3x the diameter, needle tip, shrink your arc length <1.5mm, preferally around 1mm. It takes a very steady hand and the proper amperage settings but trust me it will help your issues. I typically deal with the same kind of stuff when working on automotive exhaust projects here and there.ONDGAS wrote: If I had to guess, I would say my electrode was 3mm from the work piece.

On your 2nd and 3rd pictures, I can clearly see that the arc is just barely starting to puddle the edge of the flange and the tubing itself. Just get those two tiny puddles just a tiny bit closer and stab it with some very thin filler rod, NOT 1/16" rod. It may be "snug" but that don't make it a good fit. You can clearly see a gap because the tubing was probably not cut perpedicular to the tangent, probably to make the curve. This makes the tack that much more difficult on stainless. If one were to magnify a vband-tubing joint 100x, it should look like a tiny fillet/lap joint with no gap. If you're not already using a 2.5x or a 3.00x diopter magnifier lens, it will help out so long as you have good lighting and can see the tip of the tungsten clearly.

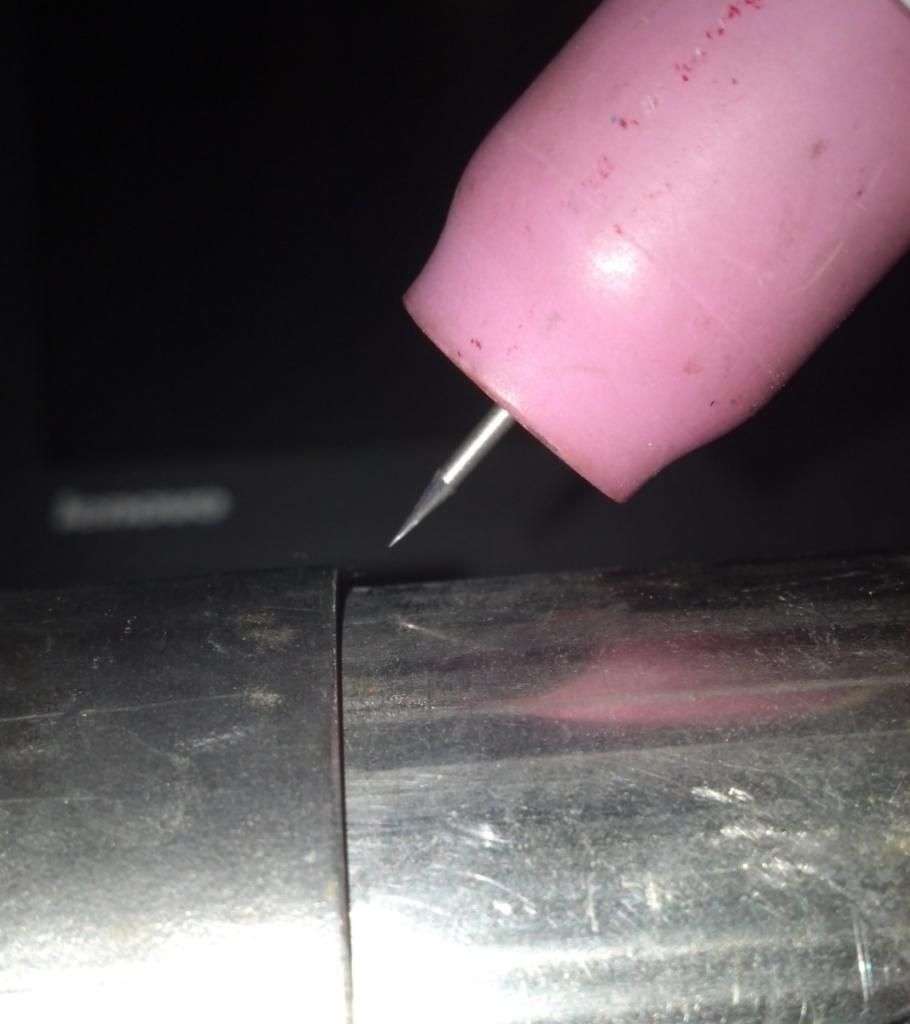

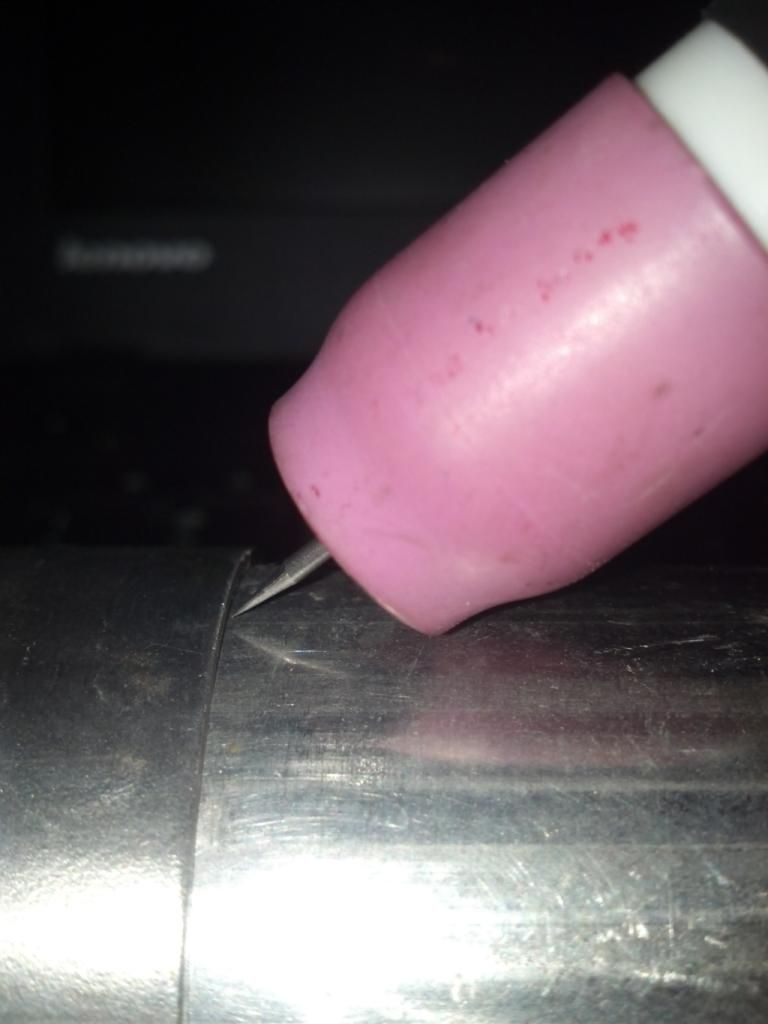

I took it a step further, to illustrate for you.

This is basically what you were working with, in terms of arc length. 16ga stainless steel tubing, slip-fitted one in the other. 1/16" diameter tungsten.

What you should to do is similar to this:

close-up:

Looks like I'm touching the base metals but I'm not. If I had to guesstimate, I'm at around 0.5-0.6mm arc length (remember to glance at the tungsten which is 1.6mm in diameter for a visual gauge reference). That will get you nice clean tacks without having the arc wander around---it is so close to the base metals it will jump to them necessarily. Hope this helps.

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities