Being cursed with a curious mind I had to see this for myself so I set out to try to replicate their experiment.

I took a 7018 out of the rod oven one Friday evening after everyone had left the shop and laid it up on top of the welding machine. Monday morning, I went back and snagged that rod that had several hours of atmospheric exposure and took it to my office. I had two small pieces of A36 scrap plate and found a guy who was standing around to be my welder. I had him weld a short bead (2.5-3" long on the scrap plate with each 7018(one properly stored in the oven and the one that I had out "exposed" all weekend), and after they cooled off enough to handle them without gloves, I dropped each into separate jars filled with baby oil. Within minutes bubbles begin to form on the center of the bead of weld that was produced with the improperly stored 7018, the other...not a single bubble. After 3 to 4 minutes the bubbles on the improperly stored test sample was streaming off the center of the cap of that weld bead and pouring towards the top of the fluid(baby oil).

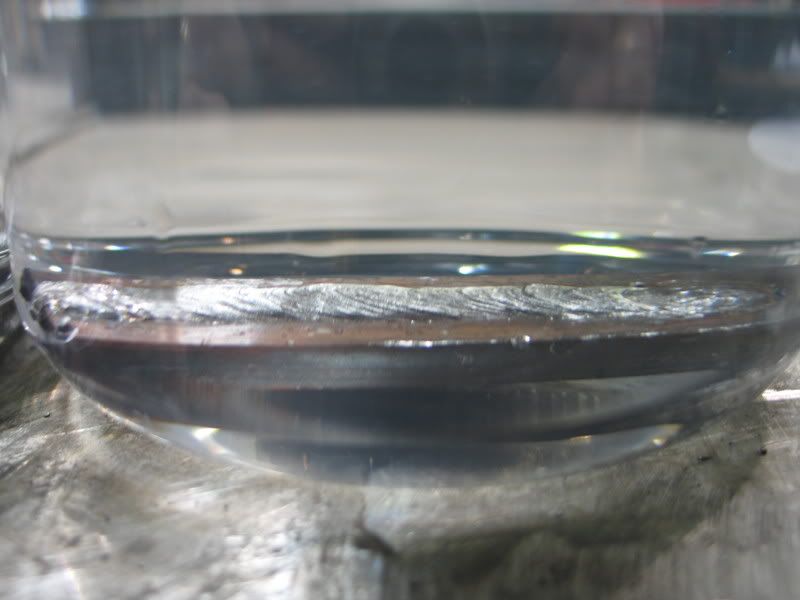

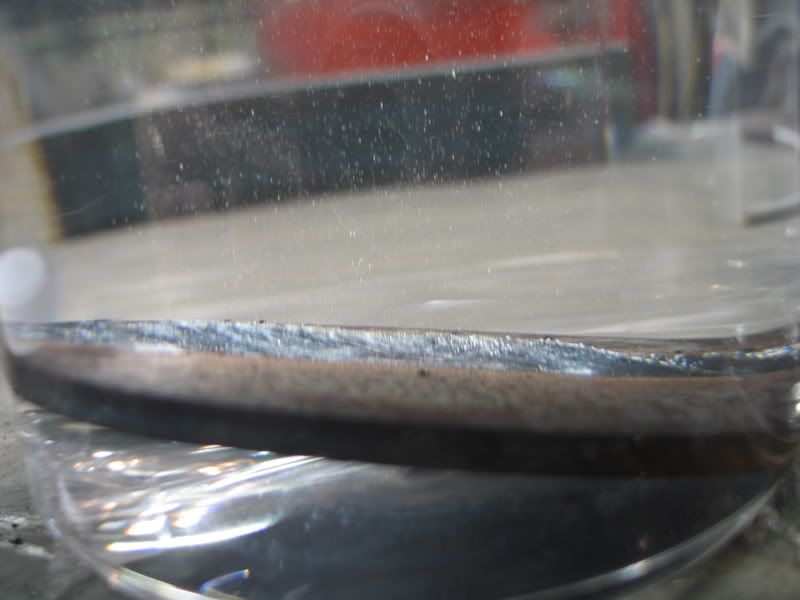

These pics were taken within less than a minute of submersion:

Properly stored sample:

Improperly stored sample:

Here's a pic of Al Moore's test:(post on AWS forum that got my attention and curiosity up)

http://www.aws.org/mwf/attachments//50/ ... Aug-08.jpg

I've posted this pic here before but, new topic and people. 7018, open packet, will not weld even after a bit of a cook in the oven and burning half the rod. (Force full drying)

I've posted this pic here before but, new topic and people. 7018, open packet, will not weld even after a bit of a cook in the oven and burning half the rod. (Force full drying)